- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

xlf-N008

-

Brand Name:

-

XLF

-

Item:

-

aluminum keyboard part

-

Material:

-

Brass/aluminium/stainless steel/plastic

-

Process:

-

Drilling/bending/milling/turning/laser machining

-

Finish:

-

Anodize/Powder coating/Sand blasting ect

-

Certification:

-

ISO9001:2008

-

OEM/ODM:

-

Avaliable

-

Product name:

-

oem machining

-

Packing:

-

Customers'requirements

-

Surface treatment:

-

Request

-

Tolerance:

-

0.05mm~0.10mm

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Stainless steel, Steel Alloys

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

xlf-N008

-

Brand Name:

-

XLF

-

Item:

-

aluminum keyboard part

-

Material:

-

Brass/aluminium/stainless steel/plastic

-

Process:

-

Drilling/bending/milling/turning/laser machining

-

Finish:

-

Anodize/Powder coating/Sand blasting ect

-

Certification:

-

ISO9001:2008

-

OEM/ODM:

-

Avaliable

-

Product name:

-

oem machining

-

Packing:

-

Customers'requirements

-

Surface treatment:

-

Request

-

Tolerance:

-

0.05mm~0.10mm

|

Custom CNC Machining Parts of Most Materials

|

|

|

|

|

||||

|

Quotation

|

According to your drawing(size, material, thickness, processing content, and required technology, etc)

|

|

|

|

||||

|

Tolerance丨Surface Roughness

|

+/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Custonize avaiable)

|

|

|

|

||||

|

Materials Avaiable

|

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, etc.

|

|

|

|

||||

|

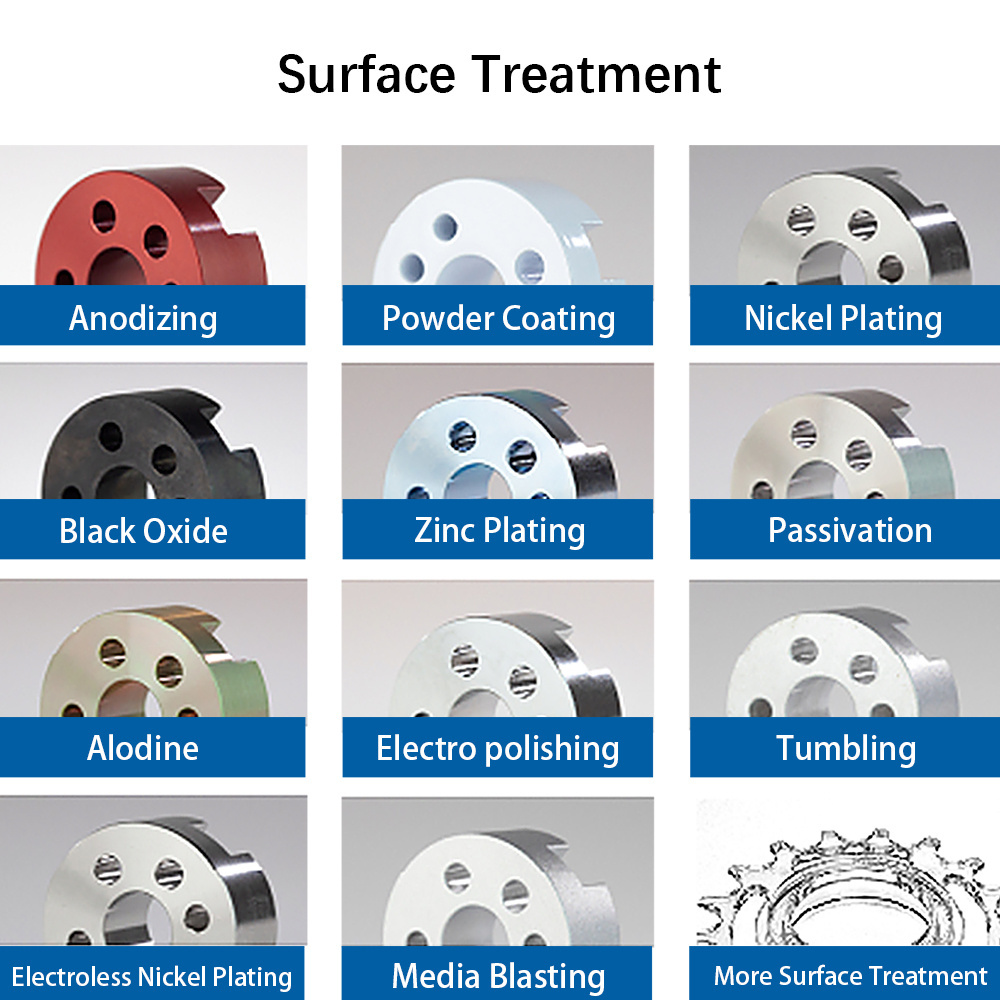

Surface Treatment

|

Polishing, general/hard/color oxidation, surface chamfering, tempering, etc.

|

|

|

|

||||

|

Processing

|

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc.

|

|

|

|

||||

|

Testing Equipment

|

CMM/Tool microscope/multi-joint arm/Automatic height gauge/Manual height gauge/Dial gauge/Roughness measurement

|

|

|

|

||||

|

Drawing Formats

|

PRO/E, Auto CAD, Solid Works , UG, CAD / CAM / CAE, PDF

|

|

|

|

||||

|

Our Advantages

|

1.) 24 hours online service & Quickly Quote/Delivery.

2.) 100% QC quality inspection before delivery, and can provide quality inspection form.

3.) 18+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

|

|

|

||||

|

|

|

|

|

|||||

|

Material Available

|

|

|

|

|

|

|||||

|

Aluminum

|

Stainless Steel

|

Brass

|

Copper

|

Plastic

|

Iron

|

|||||

|

AL6061

|

SS201

|

C35600

|

C11000

|

POM

|

20#

|

|||||

|

AL6063

|

SS301

|

C36000

|

C12000

|

Peek

|

45#

|

|||||

|

AL6082

|

SS303

|

C37700

|

C12200

|

PMMA

|

Q235

|

|||||

|

AL7075

|

SS304

|

C37000

|

C10100

|

ABS

|

Q345B

|

|||||

|

AL2024

|

SS316

|

C37100

|

etc

|

Delrin

|

Q345B

|

|||||

|

AL5052

|

SS416

|

C28000

|

|

Nylon

|

1214/1215

|

|||||

|

ALA380

|

etc

|

C26000

|

|

PVC

|

12L14

|

|||||

|

etc

|

|

C24000

|

|

PP

|

Carbon steel

|

|||||

|

|

|

C22000

|

|

PC

|

4140 / 4130

|

|||||

|

|

|

etc

|

|

etc

|

etc

|

|||||

|

Surface Treatment

|

Material Available

|

|

As machined

|

All metals

|

|

Smoothed

|

All metals+Plastic (e.g aluminum, steel,nylon, ABS)

|

|

Powder Coated

|

All metals ( e.g aluminum, steel)

|

|

Brushing

|

All metals (e.g aluminum, steel)

|

|

Anodized Hardcoat

|

Aluminum and Titanium alloys

|

|

Electropolished

|

Metal+plastic (e.g aluminum, ABS)

|

|

Bead Blasted

|

Aluminum and Titanium alloys

|

|

Anodized Clear or Color

|

Aluminum and Titanium alloys

|

Xielifeng Tech., Ltd is an ambitious

ISO

registered company, we specialized in

CNC Machining

and focusing on

superior workmanship

,

absolute quality

,

cleanliness

, and

lead time

. We're a firmly united team of talented and experienced engineers, machinists and technical consultants, who commit to helping solve problems relative to manufacturing precision and complex machined parts, including design, product costing, quality, assembly service, etc.

What makes Xielifeng Tech different from other machining company is that Xielifeng is the label of superior quality and high efficiency. We have imported much high-tech equipment during these years, for example,

4 axis CNC machining center

, which enables us to make complex and micro machine precision parts faster than ever.

Besides, we have long term cooperated partners on

sheet metal

,

stamping

,

injection

, and

die casting

as well. We can offer a one-stop service to fulfill your whole project. Absolutely we offer the highest precision and speed for our clients.

Our purpose is to help millions of buyers for custom CNC machining parts to do business easily. Welcome to discuss your ideas with our technical team

>>>

Hot Searches