- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Weight:

-

18500 kg

-

Product name:

-

Hook On Suspended Ceiling Panel Machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

After-sales Services Provided:

-

Engineers

-

Cutting blade material:

-

CR12MOV

-

Control system:

-

Touch screen

-

Touch screen:

-

Mitsubishi

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380V

-

Weight:

-

18500 kg

-

Product name:

-

Hook On Suspended Ceiling Panel Machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

After-sales Services Provided:

-

Engineers

-

Cutting blade material:

-

CR12MOV

-

Control system:

-

Touch screen

-

Touch screen:

-

Mitsubishi

Products Description

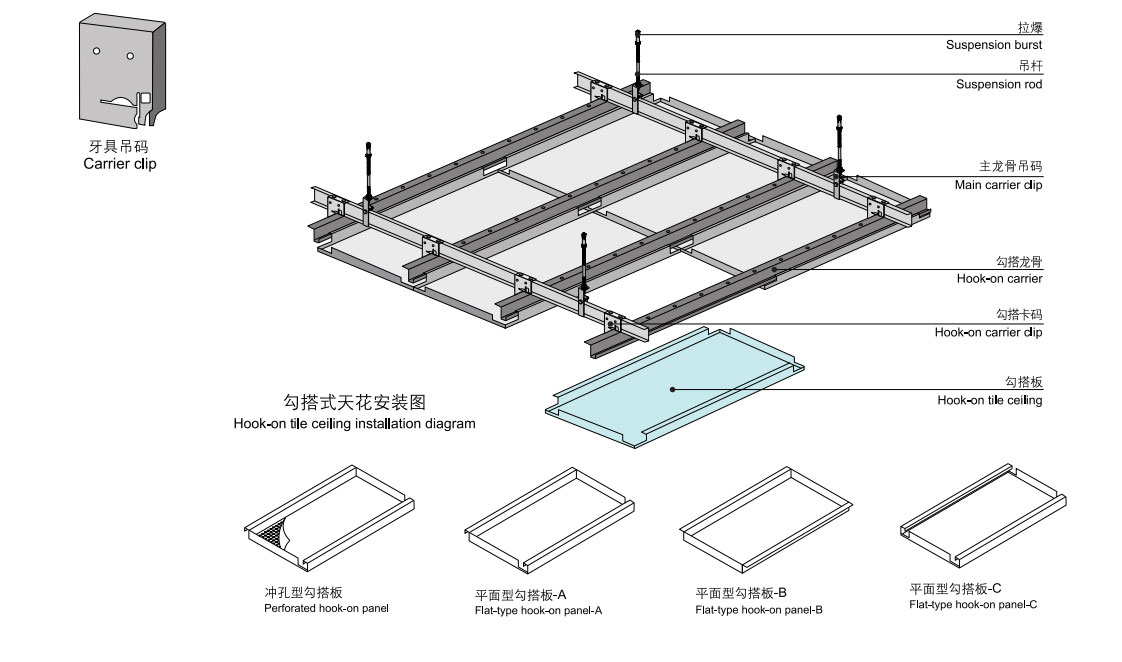

HOOK ON CEILING PANEL PRODUCITON LINE

KINGREAL Hook On Suspended Ceiling Panel production line is deigned for making hook on ceiling panel. Using the roll forming system to make the metal like aluminum and GI panel. The production line is automatic and high speed for your efficient production.

Applications

* Concealed suspension ceiling system with a variety of configurations that can fit any contemporary interior design.

* All panels are demountable without the need for special tools, allowing easy access to plenum for simple maintenance.

* Configurable panel sizes and layouts offer the designer more freedom with their design

Working Procedure

Decoiler -- Precision Leveling -- Corner Punching Machine -- Roll Forming -- Main Roll Forming Machine -- Cut to Length and Bending Machine

|

Raw materials

|

Pre-painted Aluminum or Pre-painted Galvanized steel

|

|

Hook on metal ceiling sizes

|

Width: 600-1200mm width adjustable

Length: up to 2400 |

|

Length control

|

Automatic servo control

|

|

Maximum forming speed

|

15 m / min

|

|

Roll Forming stands

|

20 roll forming stations

|

|

Machine Power

|

~ 22KW

|

- Hydraulic Decoiler

- Straightener

- Punching Station

- Roll Forming Machine

- Cut to Length and Bending Machine

- Hydraulic & Electrical System

- Straightener

- Punching Station

- Roll Forming Machine

- Cut to Length and Bending Machine

- Hydraulic & Electrical System

Technique Feature

The production line can produce the panel up to 2400mm length by setting on the control system. Using our touch screen control system is easy to control the line. When we provide the machine, we will already set the data as you production requirement. After you get the machine, just assemble it and use it.

The production line using one-step cut to length and bending, reduces manual steps in the production process and increases production speeds.

The machine you mainly use to control the production line is equipped with our 10-inch touch screen. Self-develop system can be set as our language. Like English, Russia, Spanish or other language as your wish.

Service for the KINGREAL Production Line

Install service

The machine will be setting already for your need before shipment. When you get the machine, our engineer can come to your factory to install the line. Also, the engineer can train your worker to ensure the daily production.

Warranty

KINGREAL provide 1 year warranty for our machine except the vulnerable parts and human damage. Also, there we will provide spare parts for your 1-year daily machine maintain. Maintenance parts can also be sourced through us at the back, guaranteeing the lowest possible assistance. After warranty you can get the fee for service from KINGREAL.

Hot Searches