- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

11000 KG

-

Power (kW):

-

50kw

-

Machine Name:

-

HF saw wood drying kiln/woodwork machines with large capacity

-

Effective Wood Pile:

-

1300*1300*8000mm

-

Effective Capacity:

-

13 Cubic meter

-

Power:

-

50KW

-

HF Ocsilation:

-

6.78MHz

-

Hydraulic Pressure:

-

8T

-

Vacuum System:

-

7.5KW

-

Vacuum Range:

-

-0.09Mpa(-13psi)

-

Working Principle:

-

High Frequency Dielectric Heating Generator

-

Control system:

-

PLC,Programmable Logic Controllers

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

SAGA

-

Machine Type:

-

wood drying machine

-

Marketing Type:

-

Hot Product 2020

-

Weight (KG):

-

11000 KG

-

Power (kW):

-

50kw

-

Machine Name:

-

HF saw wood drying kiln/woodwork machines with large capacity

-

Effective Wood Pile:

-

1300*1300*8000mm

-

Effective Capacity:

-

13 Cubic meter

-

Power:

-

50KW

-

HF Ocsilation:

-

6.78MHz

-

Hydraulic Pressure:

-

8T

-

Vacuum System:

-

7.5KW

-

Vacuum Range:

-

-0.09Mpa(-13psi)

-

Working Principle:

-

High Frequency Dielectric Heating Generator

-

Control system:

-

PLC,Programmable Logic Controllers

HF saw wood drying kiln/woodwork machines with large capacity

Features

- Fast drying cycle

- Automatic feeder

- Large capacity

- PLC automated systems with touch screen control panel

- Uniform heating

- No sparking or bending problem

- Veneer, panels, hardwood

- Weighing testing technology

- Fiber optic temperature testing

Description

High frequency wood drying kilns are many times faster than traditional kiln dryers. The drying process can range from several hours for thinner, softer woods to several days for thicker,harder woods.

The HFVD120-SA features an automatic feeder and a quick, automated drying cycle. It has a 50KW high frequency generator, 8T hydraulic pressure and 13m3 capacity.It is an ideal dryer for thick hard woods typically used in the furniture and flooring industry.

All models include high-tech Programmable Logic Controllers.The PLC comes with common hardwood presets ready for use. The PLC automates the drying process by starting the hydraulic pump, HF generator, vacuum pump and water system.

The water control system pulls the moisture to an external water tank which can then be drained. The weight system calculates change data to read the moisture content of the wood.

Our engineers can provide overseas installation, training and are available to provide after-sales service and maintenance. We recommend proper training for safe and prolonged use of the machinery.

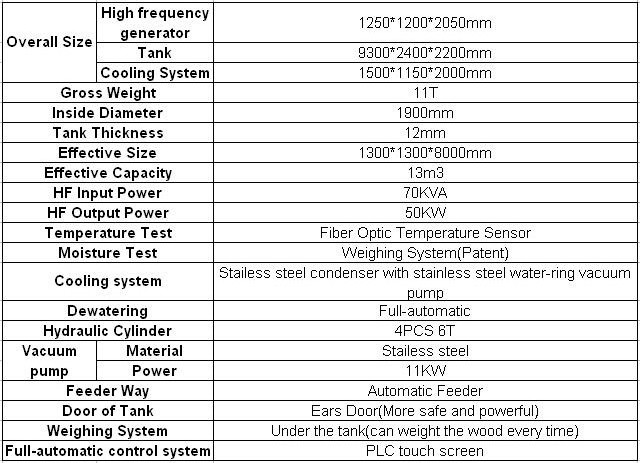

Basic Parameter of HFVD120-SA

Standard Parts

Working Live-action

Comparision of before drying and after

Certification

Installation and Transportation

Guarantee and After-sell Service

One year guarantee for whole machine except of high frequency tube

24 hours technical support by e-mail

Calling or door-to-door service

Use-friendly English software, user manual and detailed video/CD