- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

2800mm*6600mm

-

Year:

-

2019

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Degree of automation:

-

high automatic

-

usage:

-

for industrial oil,boiler,generator,car,cargo,truck diesel

-

Environmental:

-

Recycling water,no carbon black flying, no air pollution,no smell

-

Fuel request:

-

Coal/gas/wood/oil,gas bunner,oil bunner

-

Processing time:

-

20 hours for 10 T, 2hours feeding, 12 hours oil off

-

outputs:

-

45%-55% oil, 35% carbon black,15 % steel,5% gas

-

function:

-

getting oil, fuel oil, diesel from tire,plastic, rubber,MSW

-

Material quality:

-

Q245Q345R,16 thickness,X-ray welding,insulating layer

-

Machine Type:

-

plastic to oil maker machine

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Huayin

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

2800mm*6600mm

-

Year:

-

2019

-

Power (kW):

-

25 kW

-

Weight (KG):

-

25000 KG

-

Degree of automation:

-

high automatic

-

usage:

-

for industrial oil,boiler,generator,car,cargo,truck diesel

-

Environmental:

-

Recycling water,no carbon black flying, no air pollution,no smell

-

Fuel request:

-

Coal/gas/wood/oil,gas bunner,oil bunner

-

Processing time:

-

20 hours for 10 T, 2hours feeding, 12 hours oil off

-

outputs:

-

45%-55% oil, 35% carbon black,15 % steel,5% gas

-

function:

-

getting oil, fuel oil, diesel from tire,plastic, rubber,MSW

-

Material quality:

-

Q245Q345R,16 thickness,X-ray welding,insulating layer

-

Machine Type:

-

plastic to oil maker machine

Product details

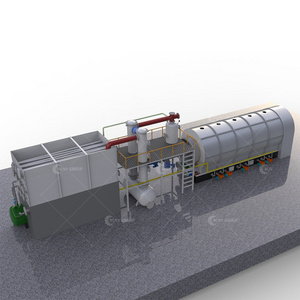

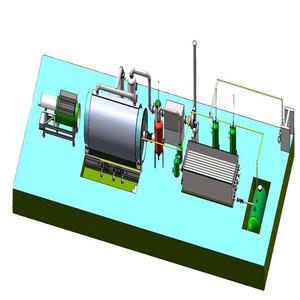

Tire pyrolysis plant is a specialized facility that utilizes thermal decomposition to convert used tires into valuable products such as pyrolysis oil, carbon black, and steel wire, providing an environmentally friendly solution for tire recycling and resource recovery.

|

Output product

|

Usage

|

|

Fuel oil

|

Used as industrial fuel for cement plant, steel plant, metallurgical plant, glass plant, power plant etc. Refined to diesel by our

distillation plant. |

|

Carbon black

|

Used as raw materials for rubber and plastic industries after further processing. Or used as heating fuel.

|

|

Steel Wire

|

Sold directly.

|

Process description

B. Heat the pyrolysis reactor. When the temperature reaches to 300-600 degrees , a large amount of oil and oil gas will be produced. The oil will be collected into the oil storage tanks.

C. Dedusting . The black smoke will be purified by the ceramic packing dedusting device which can filter the smoke effectively., thus the smoke meets the emission standards.

D. Discharge carbon black and steel wire. The carbon black will be discharged out by screw conveyor discharger.

Product Paramenters

|

Model

|

HY-05

|

HY-08

|

HY-10

|

HY-15

|

HY-30

|

||||

|

Capacity

|

5 t/d

|

8 t/d

|

10 t/d

|

15 t/d

|

30-50 t/d

|

||||

|

Working Type

|

Batch

|

Batch

|

Batch

|

Batch

|

Continuous

|

||||

|

Reactor size(m)

|

D2.2*L5.5

|

D2.6*L6.6

|

D2.8*L6.6

|

D2.8*L8.1

|

D1.2*L24

|

||||

|

Reactor material

|

Q245R

|

Q245R

|

Q245R

|

Q245R

|

310S stainless steel

|

||||

|

Power

|

29.4KW

|

29.4KW

|

32KW

|

34KW

|

100KW

|

||||

|

Heating Fuel

|

Pyrolysis oil /coal/ wood/natural gas

|

|

|

|

|

||||

|

Burners

|

3*300,000 kcal

|

3*300,000 kcal

|

3*300,000 kcal

|

4*300,000 kcal

|

12*30000kcal

|

||||

|

Landing Area

|

200m2

|

250m2

|

300m2

|

350m2

|

700m2

|

||||

|

Number of Containers

|

1*40FR+1*40HQ

|

1*40FR+2*40HQ

|

1*40FR+2*40HQ

|

1*40FR+2*40HQ

|

bulk cargo

|

||||

|

Cooling Mode

|

Circle Water

|

Noise (dB)

|

≤60

|

Working pressure

|

Normal

|

||||

Product Features

Pyrolysis reactor : Made of Q245R steel plate , high pressure and temperature resistance. the main body of the complete line, the internal reactor is rotating when production,and the temperature inside is over 500℃. Because of the excellent insulation layer , the heating efficiency is high.

Square box condenser: It offers a long condensing distance of 120 meters in total. The pyrolysis gas produced from pyrolysis reactor enters the internal condenser pipes connected in series. The condensing process is fast and efficient. The diameter of condensing pipe not only brings larger heat exchange area, but also makes maintenance easier.

The stainless steel deduster is filled with ceramic filters inside, which brings it strong dust adsorption capacity and good dust control effect.

.

Installation cases

1.Two devices to avoid back fire in production: oil-water separator and anti-back fire device. 2.Vacuum device makes the reactor work under ordinary pressure or negative pressure.

3. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

4. Dedusting : The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust removal device, then can be released into the air through the chimney.

5.Carbon black will be discharged out in sealed condition to avoid pollution.

6. In manufacturing we use auto-cutting machines, auto welding machines, auto rolling machines so that both the quality and appearance of our products can be guaranteed.

3. Temperature monitoring and Pressure gauge to monitor the pressure. If the pressure goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

4. Dedusting : The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by a powerful ceramic packing dust removal device, then can be released into the air through the chimney.

5.Carbon black will be discharged out in sealed condition to avoid pollution.

6. In manufacturing we use auto-cutting machines, auto welding machines, auto rolling machines so that both the quality and appearance of our products can be guaranteed.

Profit analysis

Assumption 8 set of 15tons pyrolysis plant , processing 2,400 tons of used tire per month.

It produces 42% of oil , 30% of cabon black and 15% of steel wires from used tires.

Water consumption is 2 tons and electricity consumption is 300kwh each machine each working day.

Labor works 8 hours by 3 shifts. It needs 20 workers.

Assumption 8 set of 15tons pyrolysis plant , processing 2,400 tons of used tire per month.

It produces 42% of oil , 30% of cabon black and 15% of steel wires from used tires.

Water consumption is 2 tons and electricity consumption is 300kwh each machine each working day.

Labor works 8 hours by 3 shifts. It needs 20 workers.

|

Cost

|

|

|

|

|||

|

Item

|

Unit price

|

Qty

|

Monthly amount

|

|||

|

Purchase of used tires

|

USD 100

|

2,400 tons

|

USD 240,000

|

|||

|

Water

|

USD 0.4

|

320 tons

|

USD 128

|

|||

|

Electricity

|

USD 0.13

|

48,000 kwh

|

USD 6,240

|

|||

|

Salary

|

USD 1,000

|

20 workers

|

USD 20,000

|

|||

|

Maintenance

|

|

|

USD 5,000

|

|||

|

Others

|

|

|

USD 5,000

|

|||

|

Total

|

|

|

USD 276,368

|

|||

|

Income

|

|

|

|

|||

|

Item

|

Unit price

|

Qty

|

Monthly amount

|

|||

|

Sales of oil

|

USD 650

|

1,008 tons

|

USD 655,200

|

|||

|

Sales of carbon black

|

USD 80

|

720 tons

|

USD57,600

|

|||

|

Sales of steel wire

|

USD350

|

360 tons

|

USD 126,000

|

|||

|

TOTAL

|

|

|

USD 838,800

|

|||

|

Profit

|

|

|

|

|||

|

Item

|

|

Monthly amount

|

|

|||

|

Profit before taxes

|

|

USD 562,432

|

|

|||

|

Profit to process each ton of used tires

|

|

USD 234

|

|

|||

Hot Searches