Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

qiangsheng

-

Voltage:

-

380v 50hz or customized

-

Dimension(L*W*H):

-

30m*3.5m*3m

-

Power (kW):

-

110

-

Weight:

-

8000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plastic Machine:

-

abs sheet extrusion machine

-

screw material::

-

38CrMoAlA nitriding

-

inverter::

-

ABB or FUJI or as customized

-

motor:

-

siemens

-

production width:

-

1220mm or as customer's request

-

Warranty time::

-

one year for abs sheet extrusion machine

-

High output::

-

200-400kg/h

-

operation person:

-

2~3 person per shift

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

30:1

-

Screw diameter (mm):

-

120 mm

-

Screw Speed (rpm):

-

80 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

qiangsheng

-

Voltage:

-

380v 50hz or customized

-

Dimension(L*W*H):

-

30m*3.5m*3m

-

Power (kW):

-

110

-

Weight:

-

8000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Plastic Machine:

-

abs sheet extrusion machine

-

screw material::

-

38CrMoAlA nitriding

-

inverter::

-

ABB or FUJI or as customized

-

motor:

-

siemens

-

production width:

-

1220mm or as customer's request

-

Warranty time::

-

one year for abs sheet extrusion machine

-

High output::

-

200-400kg/h

-

operation person:

-

2~3 person per shift

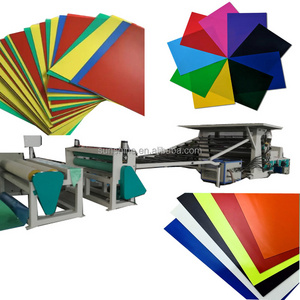

2. The products are widely used in the fields of refrigerater ,air conditioner ,auto,advertisement ,and construction ,environment protection ,etc.

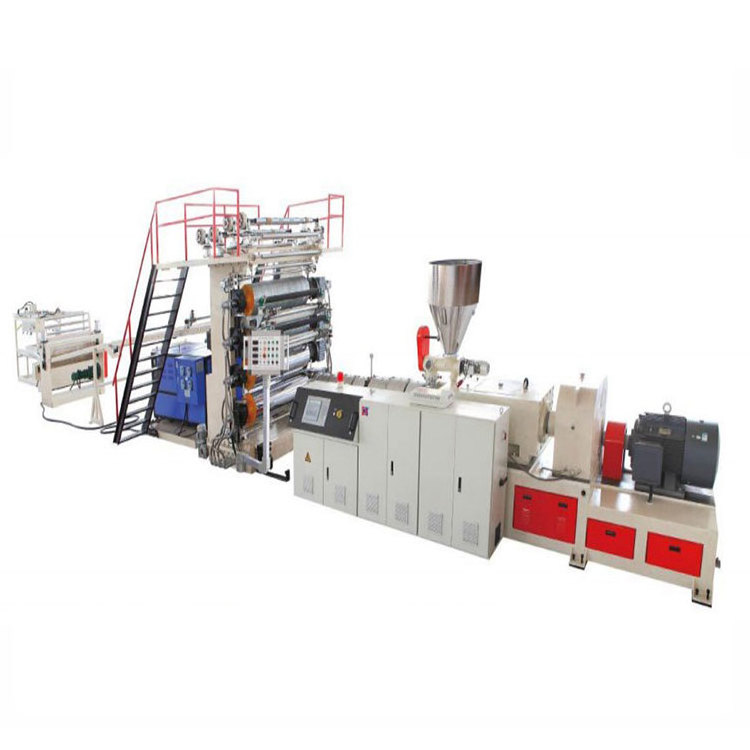

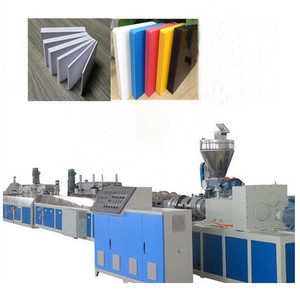

Automatic feeding system and drying machine -------- Extruder -------- Extruding mould ------- Three rollers calender ------- Haul-off unit -------- Cooling bracket -------- Cutting and strap transmission machine

Single-screw extruder.

Appropriate single-single extruder (exhause or not)( should be choosen based on different materials. Specially designed screw and advanced temperature controlling system ensure the good plasticization, high output and stable extrudig.

Screen changer and mould .

Three-roller calendering machine:

Cooling bracket: .

It is equipped with corresponding cooling guide roller, making the cooling effect better. Meanwhile, equipped with edge cutting and crush device.

Hauling off machine .

Adpts butyronitrile rubber roller and twice hauling to guarantee the stability and smoothness of plates. The hauling speed is adjusted with the three roller calendering machine synchronusly.

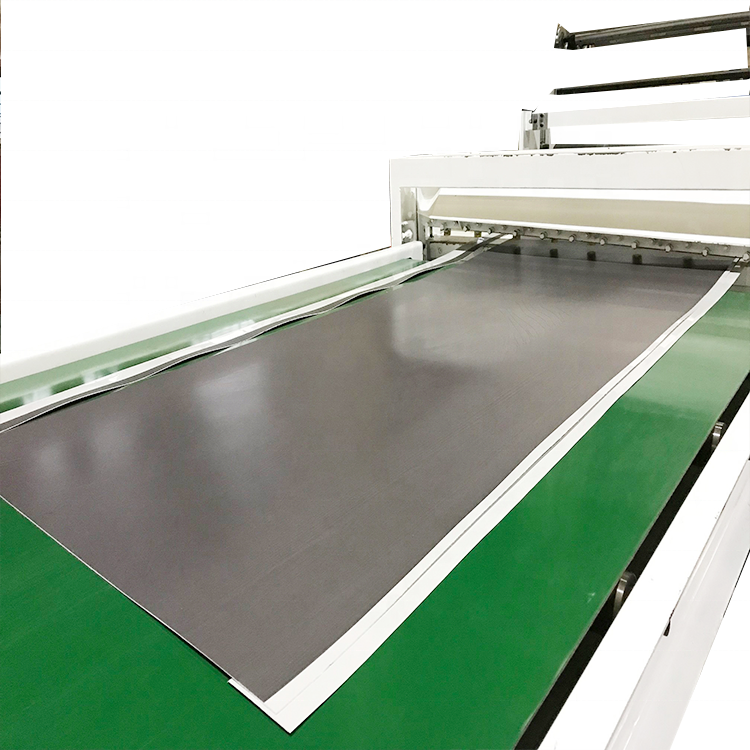

Thansverse cutting machine:

Cylinder clamping, moving cutting and speed frequency regular to guarantee the cutting speed same with plate production speed.

The products are widely used in the fields of luggage, refrigerator, air conditioner, advertisement,bathroom,automotive trim etc.

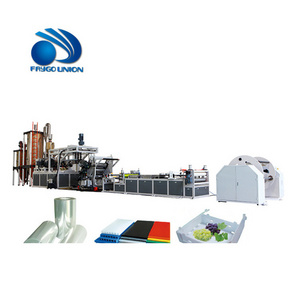

PVC PIPE PRODUCTION LINE

PVC pipe has many usages,such as: buildings,drainage,agricultural drainage, compressed air transportation and cable line.The pipes

of thickness can be varied.

PVC PROFILE PRODUCTION LINE

(2).plastic wall sheet making machine production line can be treated by double color printing & coated with glossy oil, or by heat transfer printing, or by lamation, which can make marble,wooden design on surface of product.