- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

per models

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product

-

Product name:

-

hydrocyclone

-

Other name:

-

hydrocyclone separator

-

Color:

-

customized for our hydrocyclone

-

Application:

-

Gold

-

Keywords:

-

Centrifugal Gold Concentrtor

-

After-sales Service Provided:

-

Field Maintenance

-

Processed materials:

-

Separating Stones

-

Feeding size:

-

0-2mm

-

Recovery rate:

-

95-98%

Quick Details

-

Production Capacity:

-

150cubic meter /h

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Gaoxuan

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

per models

-

Weight:

-

200 KG

-

Marketing Type:

-

Hot Product

-

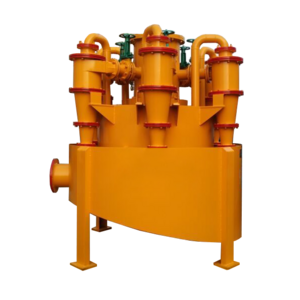

Product name:

-

hydrocyclone

-

Other name:

-

hydrocyclone separator

-

Color:

-

customized for our hydrocyclone

-

Application:

-

Gold

-

Keywords:

-

Centrifugal Gold Concentrtor

-

After-sales Service Provided:

-

Field Maintenance

-

Processed materials:

-

Separating Stones

-

Feeding size:

-

0-2mm

-

Recovery rate:

-

95-98%

Product Description

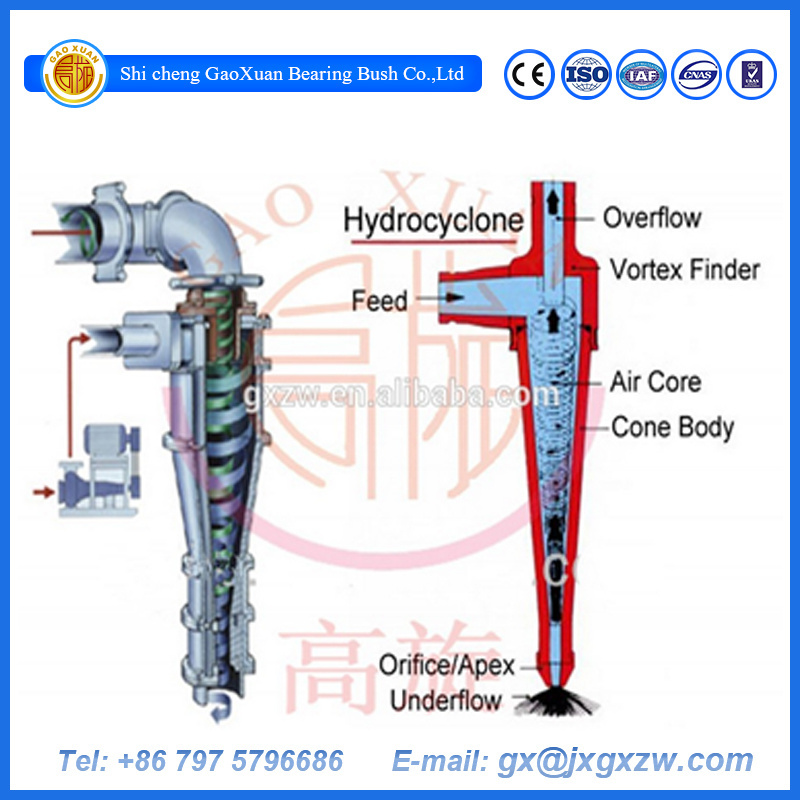

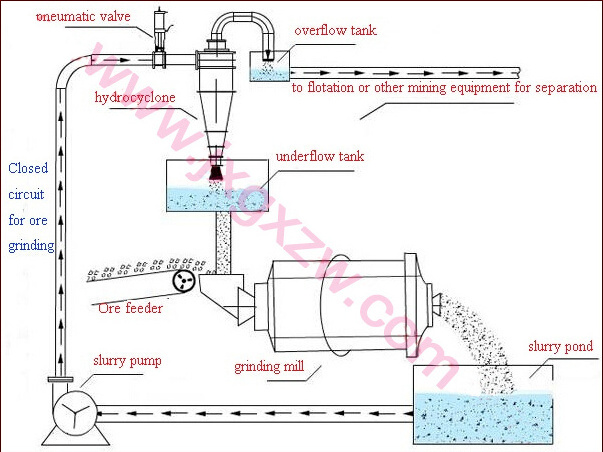

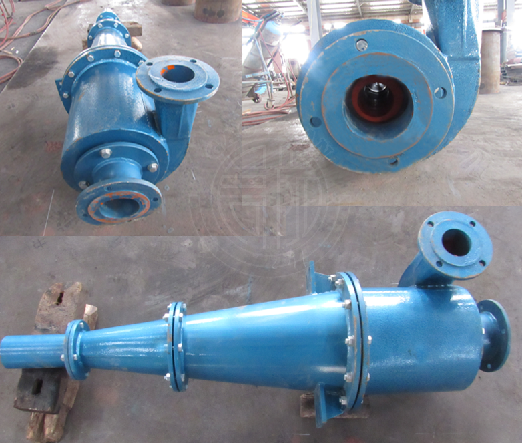

1.Introduce of Hydrocyclone:

Hydrocyclone, also called Hydraulic cyclone, which is a high efficient grading and de-sliming equipment of fine-particle

materialis and it is mainly applied to the process of second paragraph grinding, coarse or concentrates re-grinding and the

closed-circuit composed by mechanical grading machine, its grading operation is according to the particle size. In closed circuit

grinding system, it features high classification efficiency and fine over fall fineness under high mine concentration.

2.Application Fields of Hydrocyclone:

1.A hydrocyclone is most often used to separate "heavies" from a liquid mixture originating at a centrifugal pump or some othe

continuous source of pressurized liquid.

2.A hydrocyclone is most likely to be the right choice for processes where "lights" are the greater part of the mixture and where

the "heavies" settle fairly easily.

3.Generally, hydrocyclones are used in continuous flow systems so that the instantaneous liquid inflow to the hydrocyclone is

equal to the total instantaneous outflow of "lights" plus "heavies".

4.In cases where "heavies" are a very small part of the whole liquid, it is sometimes advantageous to accumulate them in the

bottom of the hydrocyclone for batchwise removal.

3.Working Principle of Hydrocyclone separator:

The feed is introduced under pressure through the trangential entry which imparts a swirling motion to the pulp. This generates a

vortex in the cyclone, with a low pressure zone along the vertical axis.An air core develops along the axis ,normally connected to

the atmosphere through the apex opening, but in part created by dissolved air coming out of solution in the zone of low pressure.

Hydroclone have repaled mechanical classifiers in many modern grinding plants,as they are more efficent, especially in the finer

size ranges,they also need less floor space and consume less power. Due to the relatively short residence time of particles within

the cyclone,the mill circuit can rapidly be brought into balance if any changes are made abd oxidation of particels within

thecircuit is reduced.

Hydrocyclone, also called Hydraulic cyclone, which is a high efficient grading and de-sliming equipment of fine-particle

materialis and it is mainly applied to the process of second paragraph grinding, coarse or concentrates re-grinding and the

closed-circuit composed by mechanical grading machine, its grading operation is according to the particle size. In closed circuit

grinding system, it features high classification efficiency and fine over fall fineness under high mine concentration.

2.Application Fields of Hydrocyclone:

1.A hydrocyclone is most often used to separate "heavies" from a liquid mixture originating at a centrifugal pump or some othe

continuous source of pressurized liquid.

2.A hydrocyclone is most likely to be the right choice for processes where "lights" are the greater part of the mixture and where

the "heavies" settle fairly easily.

3.Generally, hydrocyclones are used in continuous flow systems so that the instantaneous liquid inflow to the hydrocyclone is

equal to the total instantaneous outflow of "lights" plus "heavies".

4.In cases where "heavies" are a very small part of the whole liquid, it is sometimes advantageous to accumulate them in the

bottom of the hydrocyclone for batchwise removal.

3.Working Principle of Hydrocyclone separator:

The feed is introduced under pressure through the trangential entry which imparts a swirling motion to the pulp. This generates a

vortex in the cyclone, with a low pressure zone along the vertical axis.An air core develops along the axis ,normally connected to

the atmosphere through the apex opening, but in part created by dissolved air coming out of solution in the zone of low pressure.

Hydroclone have repaled mechanical classifiers in many modern grinding plants,as they are more efficent, especially in the finer

size ranges,they also need less floor space and consume less power. Due to the relatively short residence time of particles within

the cyclone,the mill circuit can rapidly be brought into balance if any changes are made abd oxidation of particels within

thecircuit is reduced.

Specifications

|

Model

|

Specification

|

Capacity

(m³/h) |

Separation Particle Size

(μm) |

Diameter of Overflow Port

(mm) |

|

FX-10

|

10

|

0.05-1

|

1-5

|

2-4

|

|

FX-25

|

25

|

0.3-1

|

2-10

|

5-8

|

|

FX-50

|

50

|

1.5-3

|

5-74

|

11-18

|

|

FX-75

|

75

|

2-5

|

5-74

|

15-20

|

|

FX-100

|

100

|

5-12

|

10-74

|

20-40

|

|

FX-125

|

125

|

8-15

|

20-74

|

25-40

|

|

FX-150

|

150

|

10-23

|

25-74

|

30-45

|

|

FX-200

|

200

|

17-38

|

28-80

|

40-65

|

|

FX-250

|

250

|

24-53

|

30-82

|

65-100

|

|

FX-300

|

300

|

40-100

|

36-90

|

65-120

|

|

FX-350

|

350

|

56-118

|

40-100

|

80-120

|

|

FX-375

|

375

|

74-157

|

42-105

|

90-135

|

|

FX-450

|

450

|

90-192

|

44-110

|

100-150

|

|

FX-500

|

500

|

128-300

|

50-115

|

130-220

|

|

FX-600

|

600

|

200-468

|

57-125

|

160-260

|

|

FX-660

|

660

|

237-524

|

60-130

|

180-280

|

Packing & Delivery

Ways of packing

1.Small parts packed in the wooden cases

2.Big parts packed by plastic membrane

3.The whole big machine is loaded in the container

◆ Shiping by sea/air freight

1. Usually our mining machines are shipped in 40'HQ or Flat Containers by sea.

2. Our mining equipments can be also shipped by air if customers request.

Hot Searches