- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

1900x470x1240mm

-

Weight:

-

130 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Automatic bottle cap sealing machine

-

Capping speed:

-

30-40bottles/min

-

Applicable cap size:

-

22-66mm

-

Applicable bottle size:

-

Height:50~280mm

-

Air pressure:

-

0.4-0.6MPa

-

Material:

-

Stainless steel&Aluminium

-

Marketing Type:

-

New Product

Quick Details

-

Core Components:

-

/

-

Voltage:

-

AC220/110V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

TOPCN

-

Dimension(L*W*H):

-

1900x470x1240mm

-

Weight:

-

130 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Automatic bottle cap sealing machine

-

Capping speed:

-

30-40bottles/min

-

Applicable cap size:

-

22-66mm

-

Applicable bottle size:

-

Height:50~280mm

-

Air pressure:

-

0.4-0.6MPa

-

Material:

-

Stainless steel&Aluminium

-

Marketing Type:

-

New Product

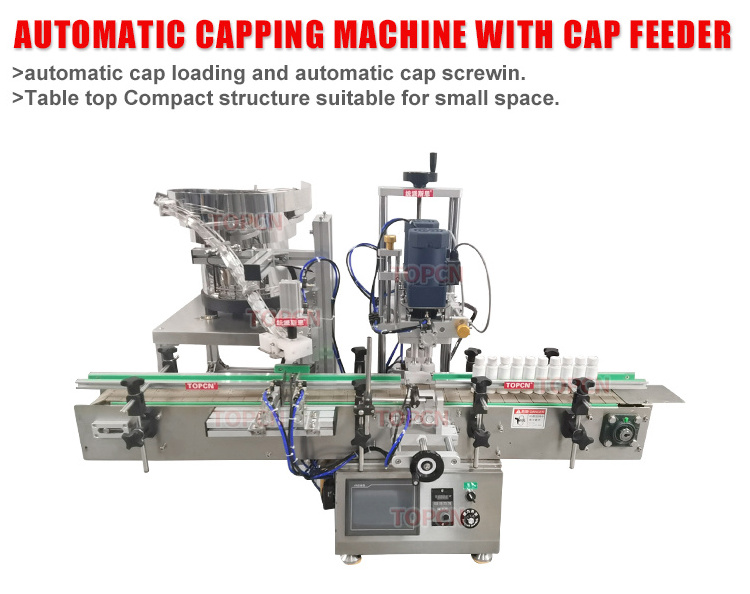

Application

This capping machine can arrange the cap and capping automaticlly, is is suitable for many sahpe of the cap, f lat round cap,aluminium round cap,flip top cap,push pull cap,sharp cap,dropper cap,washing bottle cap etc.

|

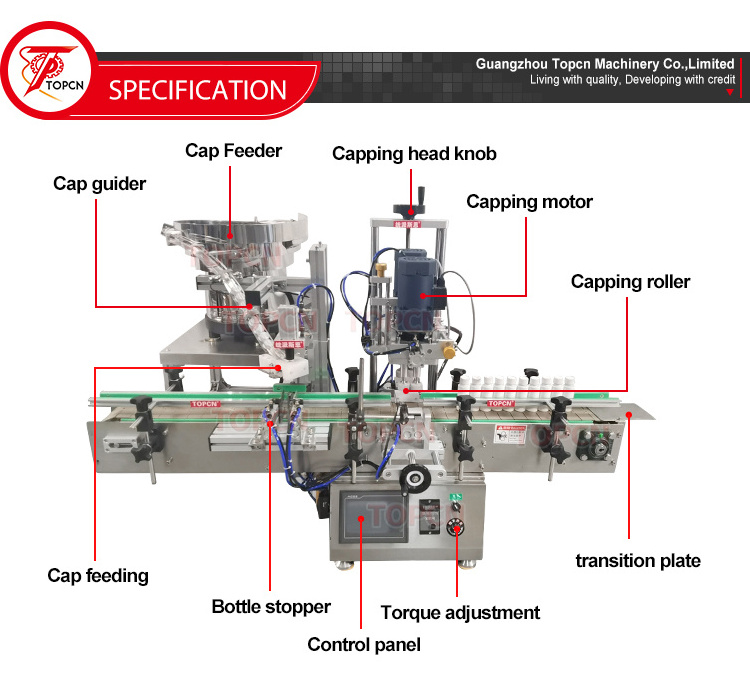

Product Name

|

Desktop Automatic Capping Machine with Cap Feeder

|

|

Bottle height

|

30-300mm

|

|

Cap Diameter

|

Standard:20mm-68mm; Customize:15mm-70mm;20mm-115mm

|

|

Bottle Size

|

Bottle height:80mm-300mm;

Can be customized 15mm-100mm; (other sizes can be customized) |

|

Working speed

|

20-30 bottles / minute (depending on bottle and cap size and shape)

|

|

Dimension

|

152x63.5x104.5Cm (Machine)50*50*118Cm(Vibratory Bowl)

|

|

Packing size

|

157*63*123Cm(Machine)About 81*66*110cm(Vibratory Bowl)

|

|

Product Weight

|

120KG(Machine)116kg(Vibratory Bowl)

|

|

Note

|

If your caps is used by pressing instead of screwing, please contact us and we will send the suitable machine for you.

|

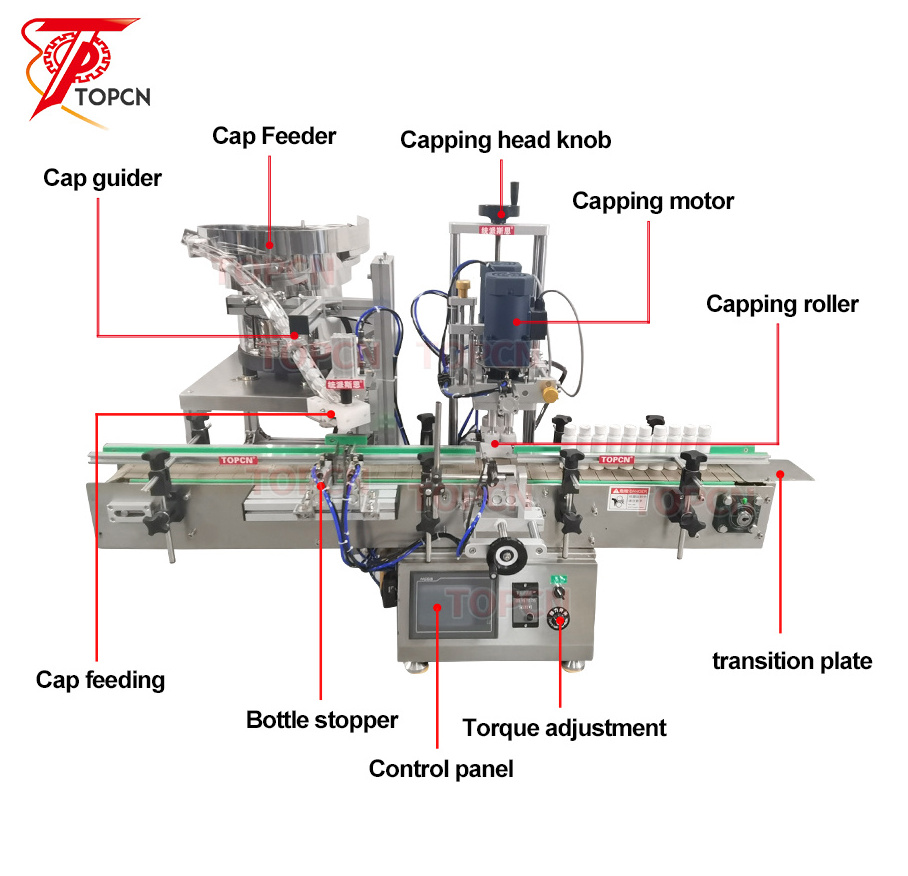

Cap Feeder

Cap feeder arrange cap on bottle automaticlly, vibrator customized as differerent cap shape, pls help to confirm the cap picture and size to our customer service before order

Cap loading

When the sensor detects the bottle cap, piston press mold to push the bottle cap in the right position, then screw the cap to ensure the effect of the capping

Rotary Knob for bottle stopper

Bottle stop postion is adjustable according to the bottle height by rotating this knob, it will convenience for customer adjust the machine

Capping adjusting knob

Screw rod adjust capping chuck for different kinds of bottle cap.left one is used for loosing or tightening middle pusher mold.right one is used for loosing or tightening the capping roller.compare with cylinder type,which is easier to adjust for customer.

Related Products

Full Automatic Production Line

* Can automatically

filling liquid

, capping bottle caps and labeling stickers at the same time.

* With conveyor, it can help to save a lot of labor.

■

1. A step-by-step free English manual and operation video to easily know how to operate the machine.

■

2. Our senior engineers are skillful and fluent in English. They have rich oversea experiences and are available to oversea services. Below with some pictures our engineers trained customers how to install and operate the machines.

Hot Searches