Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Color:

-

White,Clear

-

Hardness:

-

30 Shore A

-

Certification:

-

ISO14001,ISO9001

-

MOQ:

-

10000 pcs

-

Process:

-

LSR Injection Molding

-

Feature:

-

Non-toxic,High Transparent

-

Application:

-

Dispensing Squeeze Bottle

-

Keyword:

-

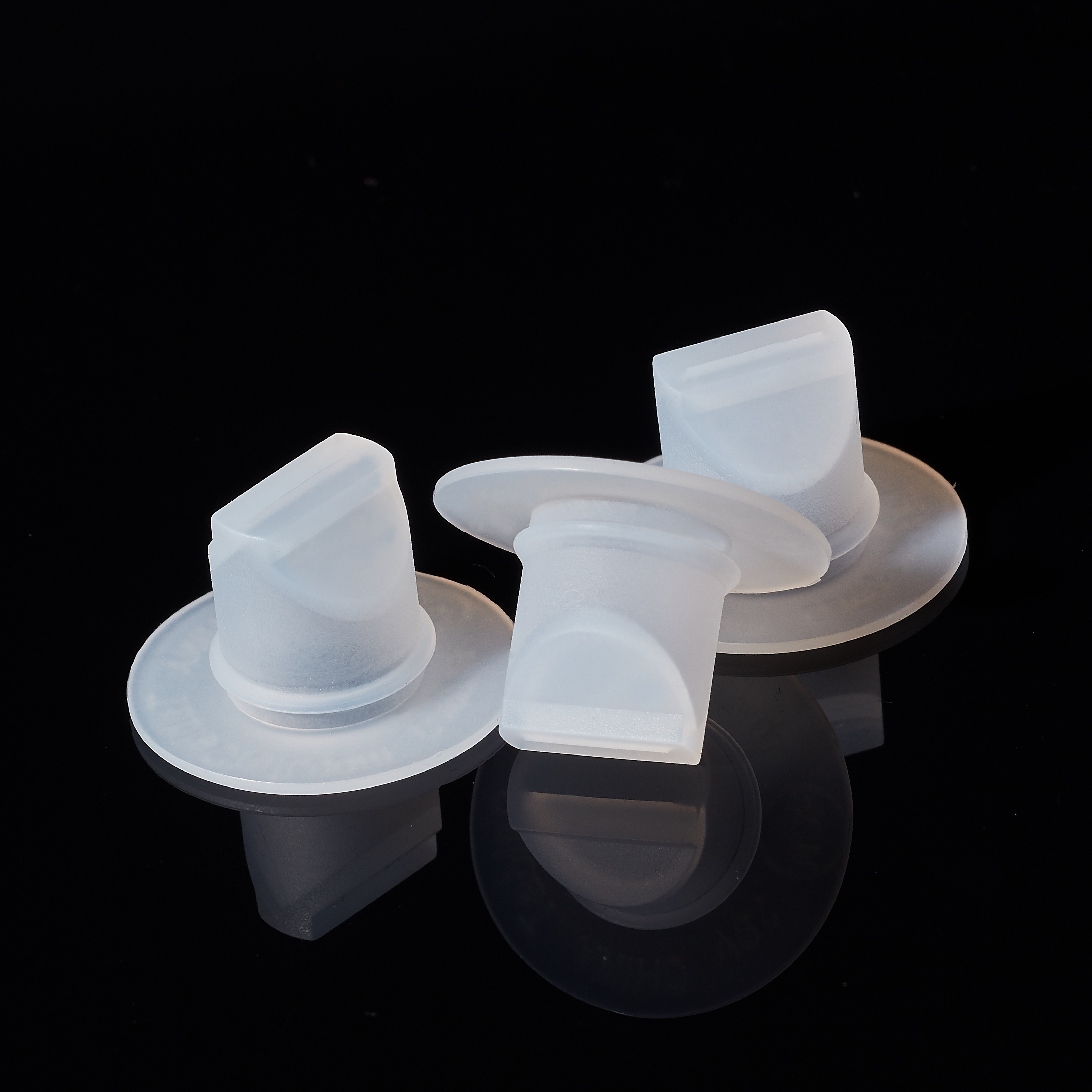

Silicone Umbrella One Way Flow Control Duckbill Valve

Quick Details

-

Place of Origin:

-

China

-

Product name:

-

Silicone Duckbill One Way Check Valve

-

Material:

-

Liquid Silicone

-

Color:

-

White,Clear

-

Hardness:

-

30 Shore A

-

Certification:

-

ISO14001,ISO9001

-

MOQ:

-

10000 pcs

-

Process:

-

LSR Injection Molding

-

Feature:

-

Non-toxic,High Transparent

-

Application:

-

Dispensing Squeeze Bottle

-

Keyword:

-

Silicone Umbrella One Way Flow Control Duckbill Valve

Product Description

Size and structure can be custom made.

Highly welcome OEM/ ODM design.

Highly welcome OEM/ ODM design.

|

Product Name

|

Silicone Duckbill One Way Check Valve

|

|

Material

|

Liquid Silicone

|

|

Color

|

Clear,White,Black

|

|

Shape

|

Duckbill Shape

|

|

Process

|

LSR Injection Molding

|

|

Hardness

|

30 Shore A

|

|

Certification

|

ISO14001,ISO9001

|

|

Feature

|

High-transparent,Non-toxic

|

|

Application

|

Dispensing Squeeze Bottle

|

Packing & Delivery

Packaging Details

Net weight:9 kgs Gross weight:9.5 kgs Carton Size: 37*25*42cm

Port Shenzhen, Ningbo, Shanghai, etc.

|

Lead Time:

|

Quantity(Pieces)

|

1 - 30000

|

>30000

|

|

|

Est. Time(days)

|

10

|

To be negotiated

|

Related Products

Our Company

YEJIA Optical Technology (Guangdong) Corporation, is one of the subsidary of Yejia Technology Group, which has 3 subsidaries,i.e., Dongguan Yejia Electronic Technology Co., Ltd., Jiaying Precision Plastic Products Co., Ltd., and Guandong Yejia Optical Technology Corporation (The Optical Division and The Silicone Division).

Yejia Optical, the silicone division, specializes in producing silicone rubber products, as a R&D, design and marketing technology corporation.

We've owned about 10000 square meters modern workshop, 26 sets LSR injection molding machines, 12 sets solid silicone vacuum compression molding machines, 100,000 class Spraying& Printing clean workshop and 100,000 class clean production workshop.

Our main products are mobile phone threeproofing parts, outdoor electronic waterproof parts, silicone medical products and smart wearables, silicone valves and other household silicone products.

Yejia Optical, the silicone division, specializes in producing silicone rubber products, as a R&D, design and marketing technology corporation.

We've owned about 10000 square meters modern workshop, 26 sets LSR injection molding machines, 12 sets solid silicone vacuum compression molding machines, 100,000 class Spraying& Printing clean workshop and 100,000 class clean production workshop.

Our main products are mobile phone threeproofing parts, outdoor electronic waterproof parts, silicone medical products and smart wearables, silicone valves and other household silicone products.

Certifications

ISO13485

IATF16949

Quality Control

Full Inspection

Deflash

Our Customers

FAQ

1. Are you trading company or manufacturer ?

We’re a manufacturer, with about 10000 square meters workshop.

We’re a manufacturer, with about 10000 square meters workshop.

2. What kind of machines do you have?

There are 26 sets LSR injection molding machines and 12 sets compression molding machines.

3. What technics do you have?

We have Liquid Injection Molding (LIM), LSR Over-molding, Compression Molding, Oil Spraying, Silkscreen Printing, Pad Printing,Laser Engraving and Assembling.

4. What’s your advantage?

With over 10 years of experience in Liquid Injection Molding (LIM), LSR overmolding with other materials, such as PC, PA, PET,PPSU, SUS, Aluminum, PCB, etc.

5. What grade of silicone materials do you use?

We have food grade/medical grade/optical grade silicone for options, the main brands we use are ShinEtsu, Polysil, Wacker, Nusil,Momentive, Dow Corning.

6. Do you offer free samples?

Yes, 10~50pcs free samples can be offered, shipping costs need to be paid by customers

7. What is your MOQ and lead time?

Normally our MOQ is 10K PCS, lead time is 10 days based on MOQ.

8. What is your terms of payment ?

Payment<=5000USD, T/T 100% in advance; Payment>5000USD, T/T 50% in advance, balance before shipment.

9. What certifications do you have?

Our factory is certificated by ISO9001, ISO14001, ISO13485, IATF16949.

There are 26 sets LSR injection molding machines and 12 sets compression molding machines.

3. What technics do you have?

We have Liquid Injection Molding (LIM), LSR Over-molding, Compression Molding, Oil Spraying, Silkscreen Printing, Pad Printing,Laser Engraving and Assembling.

4. What’s your advantage?

With over 10 years of experience in Liquid Injection Molding (LIM), LSR overmolding with other materials, such as PC, PA, PET,PPSU, SUS, Aluminum, PCB, etc.

5. What grade of silicone materials do you use?

We have food grade/medical grade/optical grade silicone for options, the main brands we use are ShinEtsu, Polysil, Wacker, Nusil,Momentive, Dow Corning.

6. Do you offer free samples?

Yes, 10~50pcs free samples can be offered, shipping costs need to be paid by customers

7. What is your MOQ and lead time?

Normally our MOQ is 10K PCS, lead time is 10 days based on MOQ.

8. What is your terms of payment ?

Payment<=5000USD, T/T 100% in advance; Payment>5000USD, T/T 50% in advance, balance before shipment.

9. What certifications do you have?

Our factory is certificated by ISO9001, ISO14001, ISO13485, IATF16949.

Hot Searches