- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3370X1260X1430mm

-

Weight:

-

656 KG

-

Warranty:

-

1 Year

-

Raw material:

-

rice/wheat/corn straw

-

Main power:

-

5.5kw

-

Bundle rate:

-

more than 99%

-

Bundle density:

-

more than 115 kg per cubic meter

-

Bale weight:

-

40-80kg

-

Bale size:

-

Dia.550*250mm

-

Processing efficiency:

-

40-60 bundles per hour

-

Poller speed:

-

350 r/min

-

Operating speed:

-

1.6-4T/H

-

Color:

-

green

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Double Crane

-

Application:

-

Bale Hay Rice Wheat Straw

-

Dimension(L*W*H):

-

3370X1260X1430mm

-

Weight:

-

656 KG

-

Warranty:

-

1 Year

-

Raw material:

-

rice/wheat/corn straw

-

Main power:

-

5.5kw

-

Bundle rate:

-

more than 99%

-

Bundle density:

-

more than 115 kg per cubic meter

-

Bale weight:

-

40-80kg

-

Bale size:

-

Dia.550*250mm

-

Processing efficiency:

-

40-60 bundles per hour

-

Poller speed:

-

350 r/min

-

Operating speed:

-

1.6-4T/H

-

Color:

-

green

-

Certification:

-

CE ISO

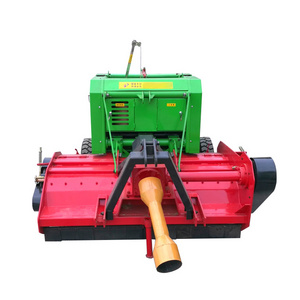

animal husbandry corn silage baler machine, mini round baler for sale used in dry season

Introduction & technical data for corn silage baler machine, mini round baler

Shandong double crane machinery brand automatic round straw baler price is a new professional

silage baling and PE film wrapping machine on straw,fodder and forage,alfalfa ect. for cow/catle

/goat/sheep farm and livestock feed mill.

Silage is to use lactic acid bacteria in the green forage to ferment the fodder under anaerobic

conditions, some of the sugar source in the straw are converted into lactic acid which

reduces the silage PH to below 4.2 to inhibit other Aerobic microorganisms such as

mildew, spoilage bacteria growing for long-term storage.

It is rich in nutrient, lactic acid and vitamins,animals have fewer digestive diseases

to eat silage. Meanwhile,the parasite and its ovum are killed after fermentation,the livestock

can reduce the occurrence of entozoic parasite. Some weed seeds also lose their ability to

germinate due to fermentation to lower the chance of livestock droppings spread the weed.

The waste crops is changed into valuable to improve the utilization of resources, compensate for

the shortage of low-quality and low-quantity forage, reduce the feeding cost and improve

the yield and quality of beef and milk.

| Powder for baling unit(motor) | 5.5kw |

| Powder for film wrapping unit(motor) | 0.55kw |

| Rotated speed | 350r/min |

| Water content in sliage | 55-65% |

| Bundle weight | 40-80kg |

| Bundle size (mm) | Dia.550*520 |

| Processing efficiency | 40-60 bundles/Hour |

| Filim wrapping efficiency | 24 seconds/3 lays |

| Overal dimension L*W*H (mm) | 3370*1260*1430 |

| Weight | 656KG |

Basic structure&working principle for corn silage baler machine, mini round baler

1.Raw materials are conveyed to bundling chamber through feeding conveyor.

2.As the bale is up to a certain density and enough big, alarm sounds and conveyor stops to feed,

reciprocating rope bundling begin and automatically to be cut after a bale is produced.

3.Air cylinder to control the chamber door open and unload the bale.

4.The bale rolls onto the rotating rack through signal turning plate, there is travel switch on the rotating

rack to activate the automatic air cylinder to clip one end of the PE film.

5.When signal turning plate touches the travel switch,travel switch releases a signal to time relay to

pull the PE film onto the bale, the rotating rack rotates to finish wrapping.

6.After the wrapping layer is up to the setting value, clutch disengages and the rotating rack stops,

The cutters on the side of rotating rack automatically cut down the PE film and press the broken

PE film into the overlap of the bale surface.

7.Put the bale onto the handcart for storage.

Main features for corn silage baler machine, mini round baler

1. A specialized round silage baler machine has two functions- silage baling &compaction by hemp

rope and PE film wrapping, one-time continuous processing can gain the final product.

2.Automatic hemp rope bundling and cutting, budling chamber door openning&closing,PE film wrapping&cutting to save time improving working efficiency &productivity. At the same time,

2 workers are enough to operate the silage baling and wrapping machine to save more labour

compared to manual operation corn silage making machine .

3. Alarm deveice for bale volume is installed to prevent silage failure caused by machine

overloading and ovesized bale volume.

4.Easy operating, high baling density, compact machine structure, nice appearance, strong and

durable, less vibration, low power consumption, simple maintenance, low labor cost.

5.Good seal of PE film can improve livestock grazing rate up to 90% and not pollute the envoirnment without liquild leakage&mildewto reduce loss. Suitable pckage and volume is easy to trasport and coomercialize and store in long time (2-3 years) for animal livestock farm or food processing facotry especially in dry season.

Final product&accessory for corn silage baler machine, mini round baler

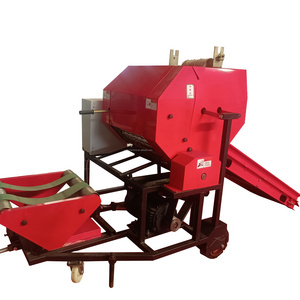

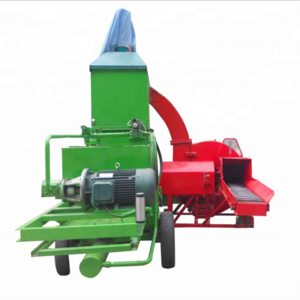

Corollary equipment for corn silage baler machine, mini round baler

The straw kneading machine has the serrated scimitar and straight blade to laniate the straw

into soft long thin filaments as material for maize silage wrapper .

| Model | SH-800 |

| Capacity | 8T/H |

| Main power | 15 Kw |

| Size: | 2400*750*1600mm |

| Weight | 500Kg |

| Hammers QTY andsize | 32 Pcs , 148*36*4mm |

| Feeding type | automatic |

A 20 GP contain 2-3 sets , A 40 GP container can hold 6-7 set with bubble filn wrapping fixed by iron cable