- Product Details

- {{item.text}}

Quick Details

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China, Shanghai, China (Mainland)

-

Brand Name:

-

Kynhor, Kynhor

-

Year:

-

2020

-

Voltage:

-

380V

-

Clamping Force (kN):

-

120

-

Power (kW):

-

50

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field maintenance and repair service, Video technical support, Free spare parts, Online support, Field installation, commissioning and training

-

Type:

-

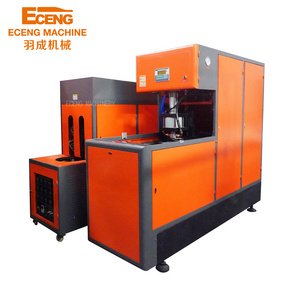

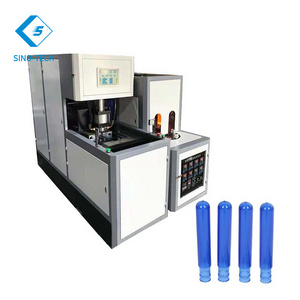

PET Bottle Blowing Machine

-

Feature:

-

speediness and damage-free

-

Usage:

-

High automation and easy operation

-

Bottle Volume:

-

100 ml-2500 ml

-

Certification:

-

CE ISO 9001

Quick Details

-

Neck Diameter(mm):

-

90 mm

-

Max.Bottle Diameter(mm):

-

300 mm

-

Max.Bottle Height(mm):

-

500 mm

-

Bottle Volume(ml):

-

2000 ml

-

Place of Origin:

-

Jiangsu, China, Shanghai, China (Mainland)

-

Brand Name:

-

Kynhor, Kynhor

-

Year:

-

2020

-

Voltage:

-

380V

-

Clamping Force (kN):

-

120

-

Power (kW):

-

50

-

Weight (KG):

-

2000 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field maintenance and repair service, Video technical support, Free spare parts, Online support, Field installation, commissioning and training

-

Type:

-

PET Bottle Blowing Machine

-

Feature:

-

speediness and damage-free

-

Usage:

-

High automation and easy operation

-

Bottle Volume:

-

100 ml-2500 ml

-

Certification:

-

CE ISO 9001

Would like to know more details , feel free to send us inquiry !

Kynhor Full Automatic Blow Molding Machine.

Full automatic blow molding machine is suitable for producing PETplastic containers and bottles in all shapes. It is widely used to produce the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, wide-mouth bottle and hot fill bottle etc.

Features of main body :

2). Automatic preform conveyer to save human cost.

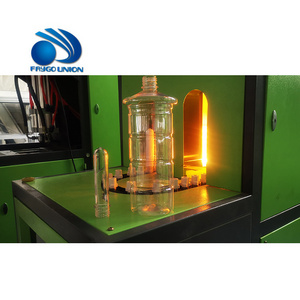

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Low cost,high efficiency,easy operation and maintenance etc, profited from the fully automatic technological process.

11). Ideal cooling system make the finished bottles without any flaws.

Would like to know more details , feel free to send us an inquiry!

1.1 New Auto Preform Unscrambler System.

1.1 New Auto Preform Unscrambler System.

*There are two photoelectric sensors to control preform-loading motor and preform-separating cylinder that will warn the operator to add the preforms into the hopper when lacks preform instead of stopping the machine.

1.2 New Heating System.

*Special oven design helps power saving and easy maintain.

*Each lamp position and temperature can be adjusted.

*Cycle air-cooling system keeps the oven temperature constantly.

Would like to know more details , feel free to send us an inquiry!

Would like to know more details , feel free to send us an inquiry!

Shanghai Kynhor Machinery Co., Ltd.

1. Standardized workshop of total 8,000 square meters.

2. The equipment will be tested and run for more than 12 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechnical stability.

3.

1 Years Warranty and 1 Years Spare parts for free .

4. Go through Alibaba.com to ensure the timely delivery and the safety of your funds .

Q.1.ARE YOU A MANUFACTURER OR TRADING COMPANY?

● Kynhor is a manufacturer with trading company who is registered in the Chinese Business Administration and has the right to operate and sell it legally.

● Kynhor cooperates with Alibaba who will supply you a lot of service to protect you .

● Kynhor has a professional engineer team who all have more than 25 years experience in beverage filling machine manufacturing .

Q.2.HOW TO VISIT OUR FACTORY?

● If you are interested in our products, you may visit our factory at any time , we can pick you up from the station or the airport near our city .

● Seeing is believing , you can see our machine quality after your visit .

Q.3.HOW TO ENSURE THE MACHINE QUALITY?

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Before shipping, the whole machine will run more than 12 hours to ensure the stable running in your factory

Q.4.HOW TO GUARANTEE YOUR FUNDS?

● We go through Alibaba.com Guarantee Service, which can protect your funds to be safe.

● We will send you pictures of the machine every week to ensure the delivery.

Q.5.KYNHOR MACHINE AFTER-SALE SERVICE

● We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly

● When you finish the preparation conditions,our fast and professional after service engineer team will go to your factory to install the machine,give you the operating manual,and train your employee until they can operate the machine well.

● We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

● We provide

1 year warranty

with spare parts free and life-long technical support .