Professional service

Super quality

Low price F

astest responds Short lead time

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

custom

-

Product name:

-

Translucent plastic dome

-

Key word:

-

Acrylic PMMA Lens Cover

-

Thickness:

-

Custom

-

Color:

-

Translucent

-

Diameter:

-

Custom

-

Lead time:

-

15-25 days

-

Material:

-

Acrylic Pmma/ PC

-

Packing:

-

Custom

-

Certificate:

-

ISO9001

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BTai

-

Model Number:

-

custom

-

Product name:

-

Translucent plastic dome

-

Key word:

-

Acrylic PMMA Lens Cover

-

Thickness:

-

Custom

-

Color:

-

Translucent

-

Diameter:

-

Custom

-

Lead time:

-

15-25 days

-

Material:

-

Acrylic Pmma/ PC

-

Packing:

-

Custom

-

Certificate:

-

ISO9001

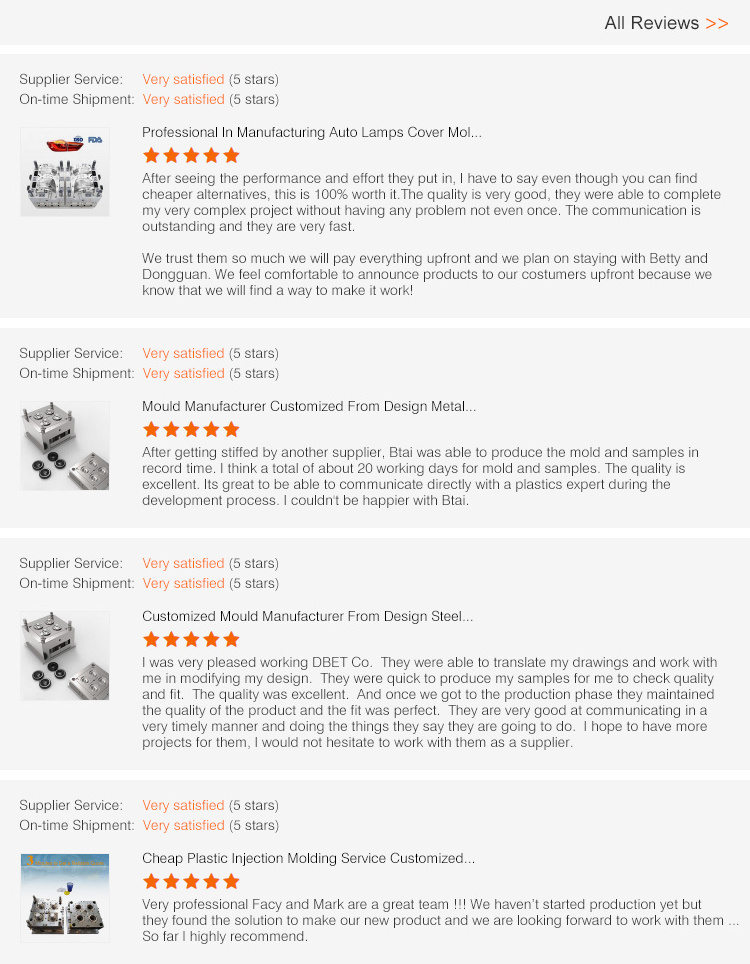

Customer feedback

Products Description

|

Business type

|

Manufacturer

|

|

|

Precise machining

|

PIR pattern machining, Optical polishing

|

|

|

Material

|

PMMA(Acrylic) & PC material for Fresnel lens, HDPE material for PIR lens

|

|

|

Dimension

|

For fresnel lens: 30-1100mm

For PIR lens: 10-70mm

|

|

|

Focal length

|

For fresnel lens: 25-1500mm

For PIR lens: 5-30mm

|

|

|

Thickness

|

2-5mm

|

|

|

Detection angle

|

For PIR lens: 30-360°

|

|

|

Sensing distance

|

For PIR lens: 4-18m

|

|

|

Reliable and best price

|

|

|

Professional suggestion on custom design

Fresnel Lens

Fresnel Lens

PIR lens

PIR lens

Other optical lens

Other optical lens

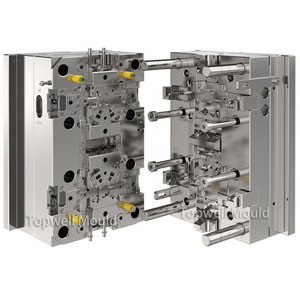

Automatic injection molding machine

The company has 22 sets of 60t-550t injection molding machines, vertical injection molding machines and optical injection molding machines.

How to get suitable and quality mold and plastic parts?

1.

Our professional engineers submit suggestions on the mold and part structure before quotation.

2.

Mold flow analysis before mold design, experienced mold designer and mold maker.

3.

Experienced injection molding engineers.

4.

Strict QC checking on the molds and parts.

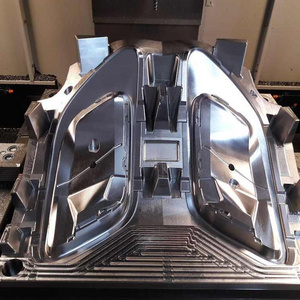

Mold making process

1. P

roduct samples or 3D design drawings

2.

DFM report and mold design

3. Material Preparation

4. CNC machining

5. EDM Machining

6. Mold Trail

7. Sample Inspection

8.

Pre-production

9.

Product packaging

10. Plywood package

11. After Sale Service

Are you bothered by the following questions?

1. Low precision mold, short mold life , high cost of changing molds frequently.

2. Bad quality product, loose tolerance product.

3. Bad quality steel with cracked surface or rough surface.

4. Not environment friendly materials with odor and bad performance.

5. Long lead time and production time.

6. Lack of professional knowledge and experience, difficulty in English communication.

7. High scrap rate of injection molding and low efficiency.

2. Bad quality product, loose tolerance product.

3. Bad quality steel with cracked surface or rough surface.

4. Not environment friendly materials with odor and bad performance.

5. Long lead time and production time.

6. Lack of professional knowledge and experience, difficulty in English communication.

7. High scrap rate of injection molding and low efficiency.

Our Advantages

Submit quotation within

8

hours

Quality Guarantee

We have cooperated with raw material suppliers for 20 years, with stable and efficient cooperation.

Free maintenance

Maintain and keep molds in good condition.

Remark:

We are honest and we won't use your mold to make any parts for other business.

20 year professional team

We have the professional engineer teams and sales teams, mostof them have more than 20 years experience in mold-makingindustry and injection industry, especially for household, electronics and automotive products.

Advanced equipment

We have the high quality CNC and EDM machines from HAAS, MOKRON, OKUMA, AGIE, MAKINO, such as: 4-axis and 5-axis CNC machines, can offer stable and accurate processing ability.

Fast delivery time

For small prototype mold: 10 days.

For complex mold: 20-30 days.

For prototype: 3-5 days.

For mold design: 2-5 days.

One stop service

We offer products design and 3D print service, we have more than 22 sets injection machines and 3 aseembly lines, we can provide production run, product assembly and Product packaging for direct sale service.

High quality and factory price

We have lSO9001 International Quality Management System, aswell as Chinese Production Cost Control Experience, So we canhelp you save about 20%~30% Manufacturing cost when youcompare with others.

High speed after-sales service

We offer good after-sale service within 5 years after customer receive the mold, Provide 16 hour online consultation, Most of our customers work with us more than 15 yearsand still trust ,satisfy and do with us.

Certifications

Our Shipping Advantages

1.

Fast delivery time,

about 3-5 days door to door service by express, about 20-45 days door to door service by sea.

2. My company give additional

discount 70%

on the shipping cost to customers.

3. Door to door service include all taxes,

No need to pay an extra cent.

Hot Searches