- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Rfm

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

4000 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

ppgi

-

color:

-

Customized

-

motor brand:

-

china famous brand

-

name:

-

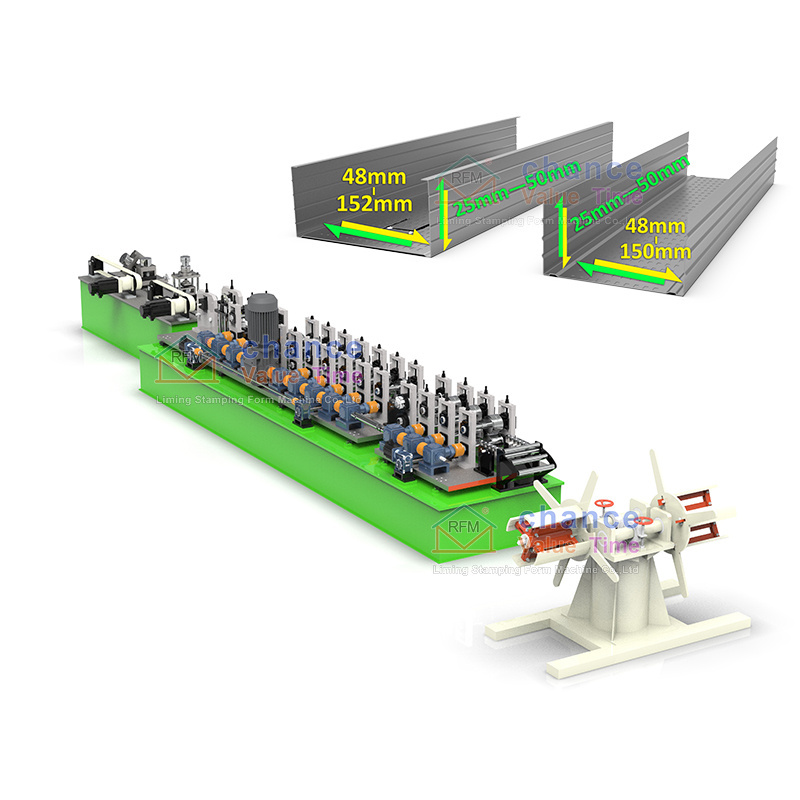

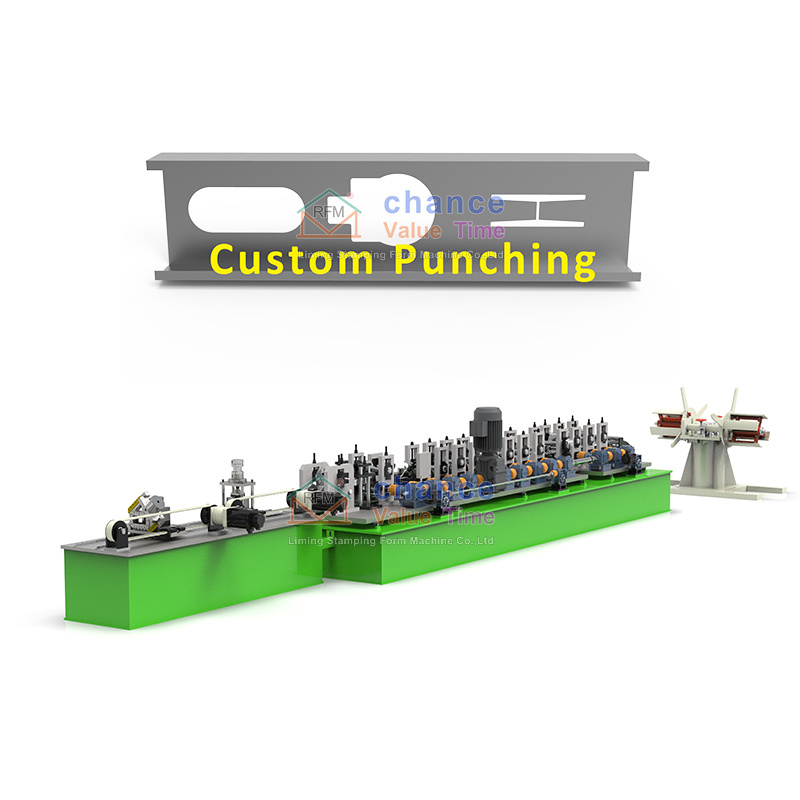

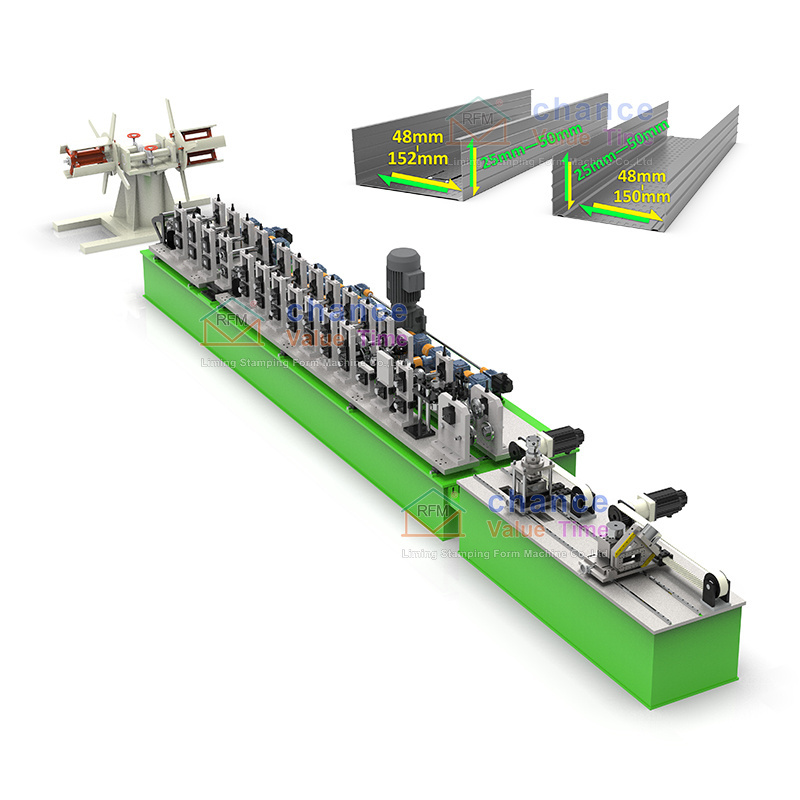

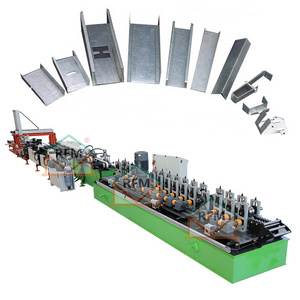

Drywall Metal Stud Machine Stud&Truck Roll Forming Machine

-

plc:

-

mitsubishi/delixi/siemens

-

operate style:

-

automatic

-

profiles:

-

Customer request

-

thickness:

-

0.3-1.0mm

-

cutting blade material:

-

cr12 with quenched treatment

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-1mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Rfm

-

Voltage:

-

380V 50Hz 3Phases

-

Dimension(L*W*H):

-

5000*800*1200Mm

-

Weight:

-

4000 kg

-

Feeding width:

-

Customer request

-

Marketing Type:

-

New Product 2021

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

raw material:

-

ppgi

-

color:

-

Customized

-

motor brand:

-

china famous brand

-

name:

-

Drywall Metal Stud Machine Stud&Truck Roll Forming Machine

-

plc:

-

mitsubishi/delixi/siemens

-

operate style:

-

automatic

-

profiles:

-

Customer request

-

thickness:

-

0.3-1.0mm

-

cutting blade material:

-

cr12 with quenched treatment

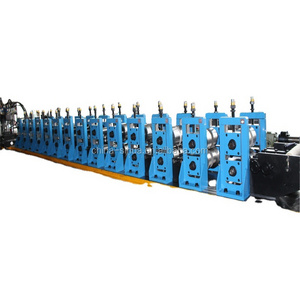

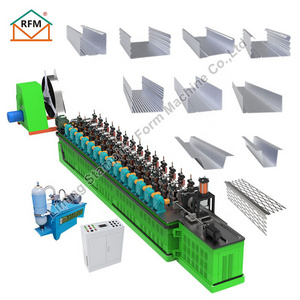

Fully Automatic Metal Stud C-Slot Roll Forming Machine Chinese Famous Brand Keel Forming Machine

Click the image below to start online customization for the design you want.

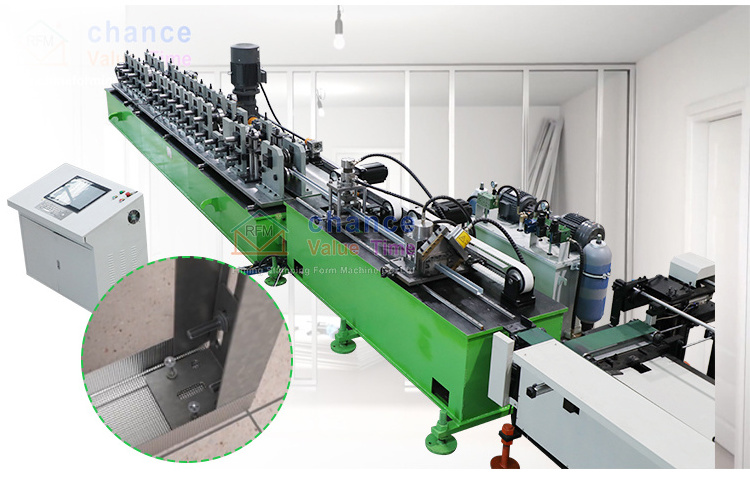

Our company provides machines with the Mengniu archway structure of our company. We provide supporting software to configure and test run the machine for you before transportation to ensure rapid investment in your factory. The product parameters can be determined in advance through the software to prevent bringing Waste of materials. In the overall frame of the fuselage we used the gb 360 heavy i-beam, the fuselage stable, long life, no sag of the fuselage. The machine is equipped with double bearings to ensure the quality of the products. Even if one of them is broken, there is another bearing to ensure the operation. Our products are inspected by professional machines and quality inspection teams.

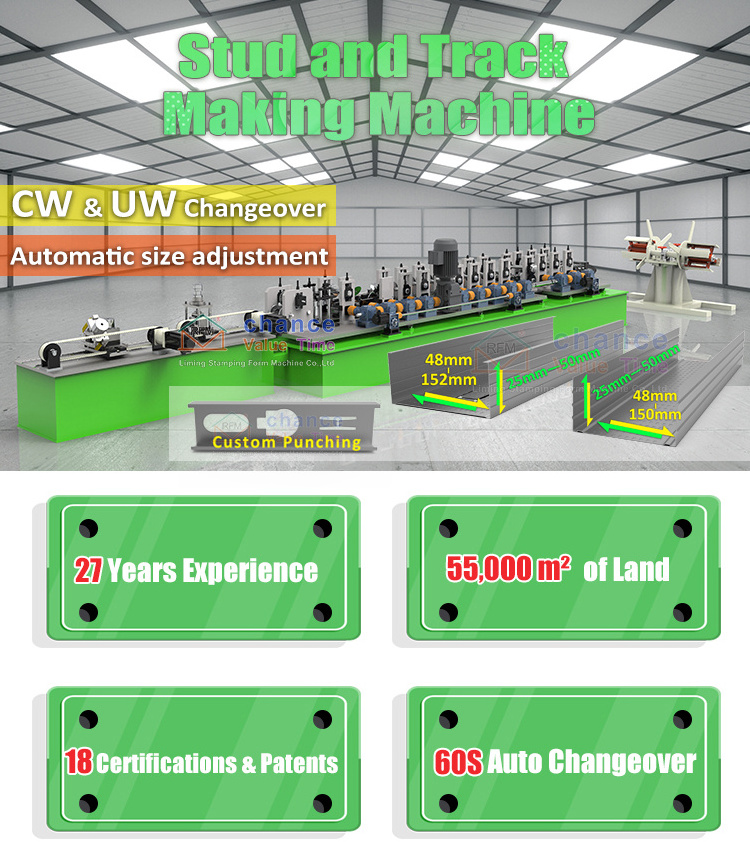

Liming Stamping Form Machine Co.,Ltd. occupies an area of 55,000 square meters and 6 large production plants. It has been established in 1996 with many years of production experience, serving 156 countries, 4 international machinery patents, 10 Chinese machinery patents, nationally certified high-tech company.China's top three steel-building materials equipment factories.

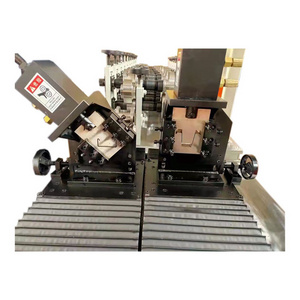

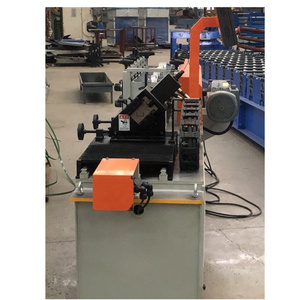

Machine Details

Manufacturing Technique

|

No.

|

Description

|

Quantity (set)

|

Remark

|

|

1

|

Double head decoiler (option)

|

1

|

|

|

2

|

Guider

|

1

|

|

|

3

|

Leveler

|

1

|

|

|

4

|

Servo Feeder

|

1

|

|

|

5

|

Puncher

|

1

|

|

|

6

|

Pre-cutter

|

1

|

|

|

7

|

Conveyor

|

1

|

|

|

8

|

Roll forming system

|

1

|

|

|

9

|

Forming system base

|

1

|

|

|

10

|

Size Auto adjuster

|

1

|

|

|

11

|

Gear Transmission system

|

1

|

|

|

12

|

Auto Stacker

|

1

|

|

|

13

|

Safety fence

|

1

|

|

|

14

|

Hydraulic station

|

1+1

|

|

|

15

|

Control box

|

1

|

|

|

16

|

Spare parts and tools

|

1

|

As standard

|

|

17

|

IOT

|

1

|

|

|

18

|

Printer

|

1

|

|

Warranty:

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

Quality inspectors test the hardness and speed of machine parts to ensure safe and stable operation of the machine and increase

production.

production.

|

No

|

Item

|

Parameter

|

Note

|

|

1

|

Max Working Speed

|

60 m/min

|

|

|

2

|

Forming station

|

Around 14

|

|

|

3

|

Power

|

380 V/3PH/50HZ.

|

Total 60 KW

|

|

|

|

Decoiler: 3+3 KW

|

|

|

|

|

Leveling Motor: 5.5 KW

|

|

|

|

|

Servo Feeding motor: 5 KW

|

|

|

|

|

Hydraulic Stations: 15 KW

|

|

|

|

|

Main motor: 22 KW

|

|

|

|

|

Stacking &Packing: 3 +3KW

|

|

|

4

|

Total Weight

|

About 17200 KGS

|

|

|

|

|

|

|

Machine assembly

Partner

After-Sales Service

Hot Searches