- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jopar

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

21.5m*1.2m

-

Weight:

-

6500 kg

-

Name:

-

pipe making machine

-

Color:

-

Bule,Green,Orange,Grey, etc.

-

Pipe shape:

-

Sqaure/ Round/Rectangle

-

Grinding:

-

automatic grinding,manual grinding

-

application:

-

railing ect

-

Market:

-

India/the Middle East ect

-

Usage:

-

industrial pipe,decorative pipe

-

Tube Range:

-

8-51mm

-

Thickness:

-

0.3-2.2mm

-

Useful life:

-

40years

Quick Details

-

Pipe Material:

-

Stainless steel

-

Production Capacity:

-

0-10m/min

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jopar

-

Voltage:

-

220/380/415/420/440V

-

Power:

-

11KW

-

Dimension(L*W*H):

-

21.5m*1.2m

-

Weight:

-

6500 kg

-

Name:

-

pipe making machine

-

Color:

-

Bule,Green,Orange,Grey, etc.

-

Pipe shape:

-

Sqaure/ Round/Rectangle

-

Grinding:

-

automatic grinding,manual grinding

-

application:

-

railing ect

-

Market:

-

India/the Middle East ect

-

Usage:

-

industrial pipe,decorative pipe

-

Tube Range:

-

8-51mm

-

Thickness:

-

0.3-2.2mm

-

Useful life:

-

40years

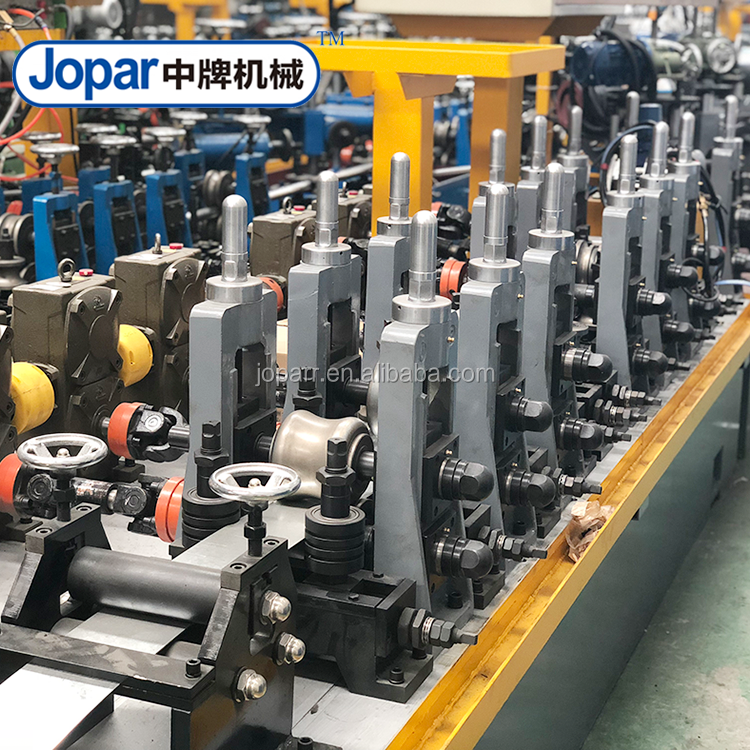

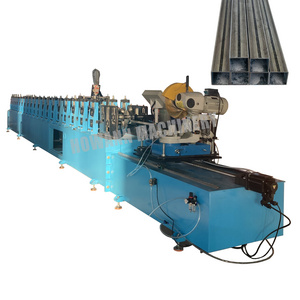

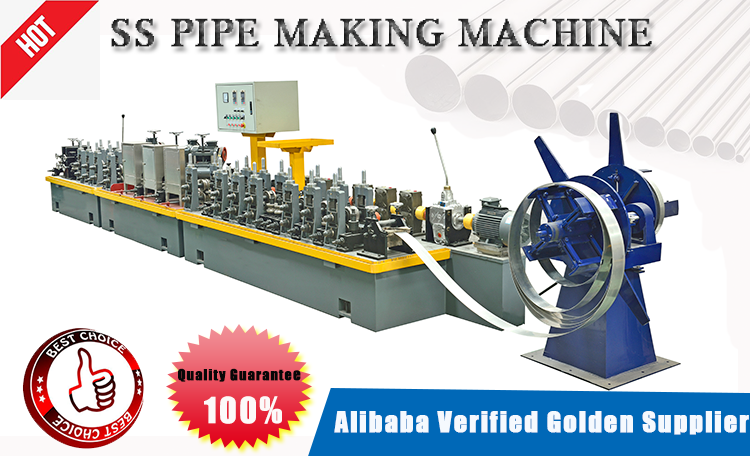

High Quality SS Square Tube Mill Line Steel Pipe Making Machine

This machine is mainly used for the production of Stainless Steel/Carbon Steel pipes/tubes with

heavy thickness which applied in decoration, furniture,hand rali,outdoor decoration,household

appliances industry ,steel pipes/tubes etc.(round tubes,square tubes,rectangle tubes).

Technical Parameter

| Model |

Horizontal Shaft O.D. |

Vertical Shaft O.D. |

Tube Range |

Thickness | Drive Motor | Dimension |

| ZP-S40 | 40mm | 30mm | 8-51mm | 0.3-2.2mm | 11KW | 21.5m*1.2m |

| ZP-S50 | 50mm | 30mm | 25-76mm | 0.4-2.5mm | 15KW | 24m*1.3m |

| ZP-S60 | 60mm | 40mm | 50-114mm | 0.5-3.0mm | 18.5KW | 26m*1.5m |

| ZP-S80 | 80mm | 50mm | 89-168mm | 0.8-4.0mm | 22KW | 32m*2.5m |

| ZP-S100 | 100mm | 60mm | 114-219mm | 1.0-6.0mm | 30KW | 36m*2.8m |

| ZP-S120 | 120mm | 80mm | 168-325mm | 1.5-8.0mm | 37KW | 40m*3.0m |

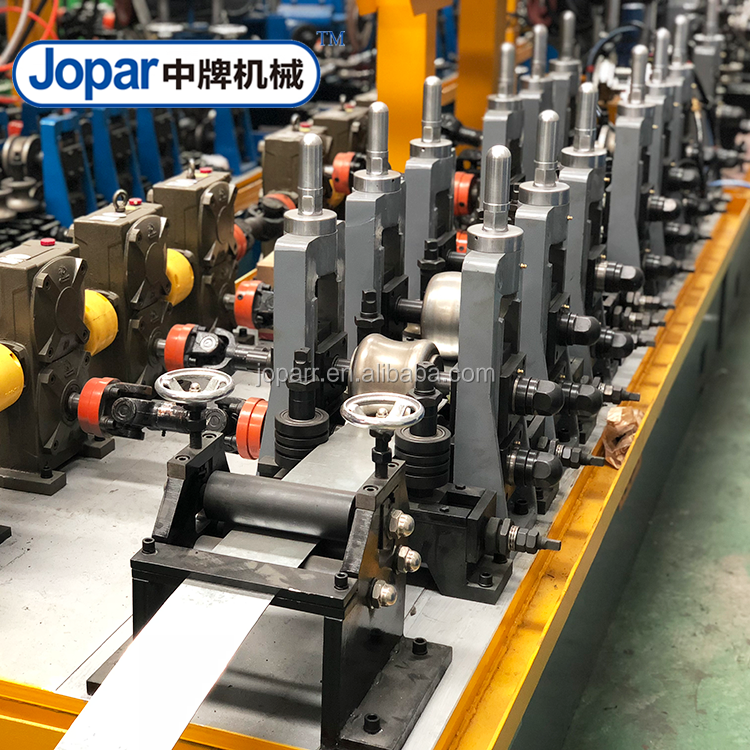

The Stronger Pipe/Tube Production Line Solutions

Optional type of machine:

Standard configuration:

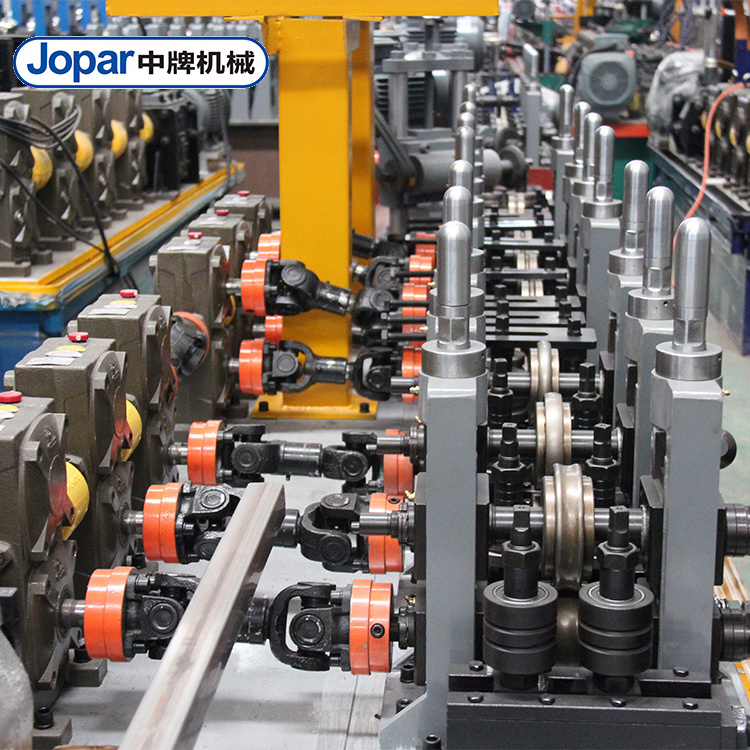

1. Uncoiler : Mechanical tension bridle manual adjustment .

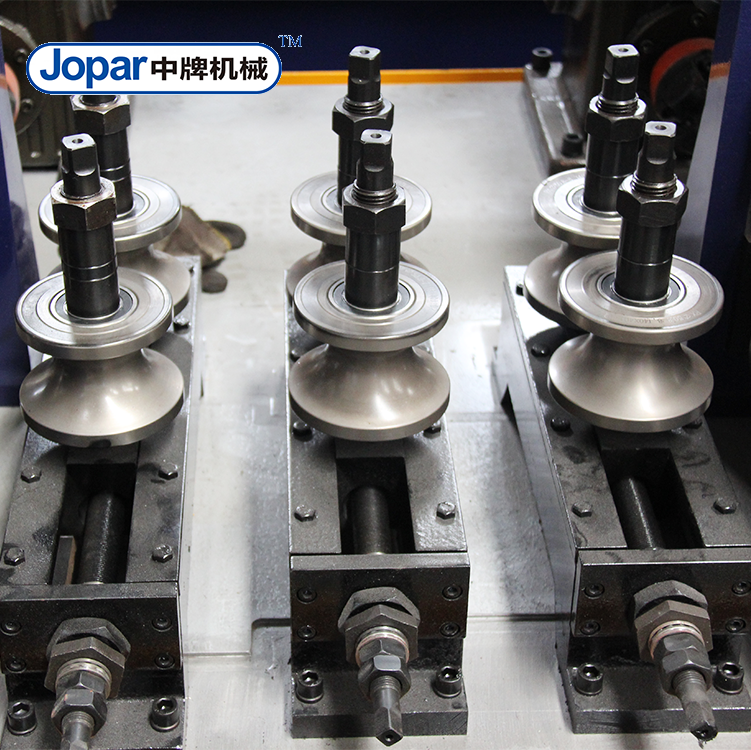

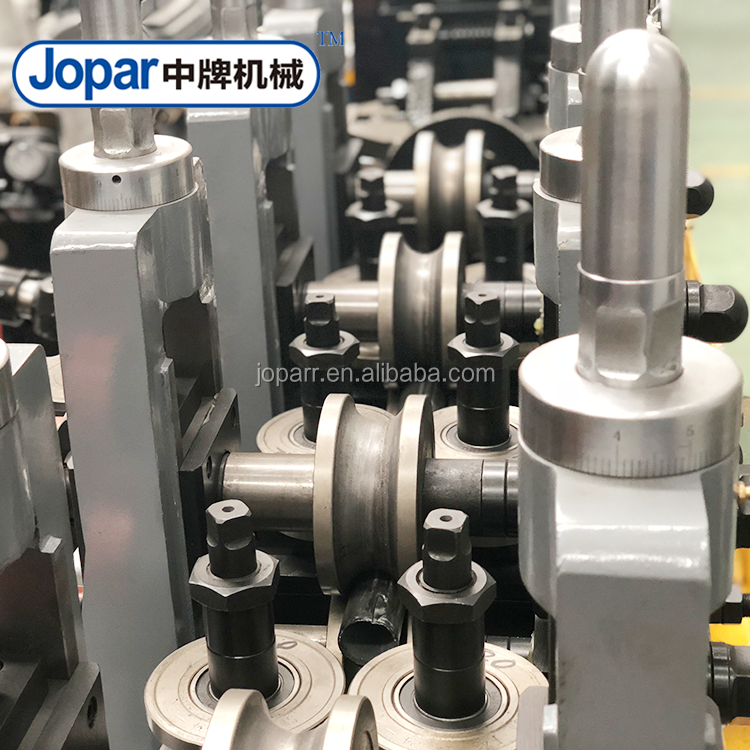

2. Horizontal and vertical holder: Passed heat treatment to make black. The holder will rust protection when used.

3. Bearing : Used deep groove ball bearing

4. Welding : Argon welding machine (500A) .

6. Grinding head: Manual by hand to debugging.

7. Cutting machine: Abrasive cutting machine.

8. Drive motor used Siemens brand, grinding motor used Kaiyuan brand.

High configuration.

1. Uncoiler: Hydraulic tension bridle automatic adjustment.

2. Horizontal and vertical holder: Passed electroplate treatment . Except rust protection, also can make holder more stable and can bear more pressure.

3. Bearing: Used Needle bearing and cone bearing.

4. Welding : High configuration Plasma and Quasi ion welder, can improve welding seam quality also can save more produce cost.

5. Welding equipment: Welding torch protective box, after used ,the welding line will easy to grinding and can protect the welding line , Have fast speed, low cost, easy grinding.

6. Grinding head: Automatic type grinding head (can manual or fully automatic optional)

7. Cutting machine: Metal saw cutting or Band saw cutting machine.

8. All motor in the pipe making machine used Siemens brand.