1. Heater should be protected against damp during storing or installing to ensure the performance of the heater.

2. In order to be sure of well-distributed lot of each and groups, heater should be divided before assembling. The tolerance of the resistance of each one cannot exceed by 10% each other.

3. Heater is hard and brittle, please be careful when assembling and maintaining so as to avoid damage.

4. When operating the electric furnace at the beginning, the voltage should be increased slowly and cannot be fully loaded at once. Otherwise the larger current will be resulted in the damage of heater.

5. When heater is damaged and need to be changed, the resistance of new ne should follow the increasing resistance. If many are damaged or resistance increased too much, heater should be changed.

6. Silicon Carbide (SIC) heating elements is a non-metal electric heating element made from SiC as its main raw materials. It has some specific properties, such as low expansion coefficient, little deformation, stable chemical property, long service life, easy installation and maintenance, etc.

7. Usage: Silicon Carbide (SIC) heating elements can usually make use for furnace which temperature from 600-1600. It can be directly used in an air atmosphere, without any protection atmosphere. It is extensively used in the fields of metallurgy, ceramics, glass, machinery, analysis test, semiconductor, science & research and so on.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GRD

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1 KG

-

Working Temperature Range:

-

800 - 1400 ℃

-

Service life:

-

Over 2000 hours

-

Application:

-

Sintering, melting

-

Size:

-

Cuztomized

-

Shape:

-

DB, ED, U, W, customized

-

MOQ:

-

1 Piece

-

Delivery time:

-

7-15 days

-

Packing:

-

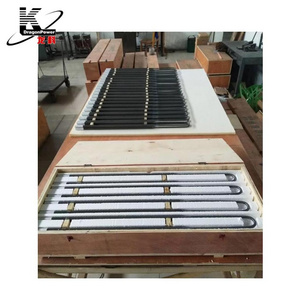

Standard export wooden case

-

Certification:

-

CE, ISO

Quick Details

-

Type:

-

Air Heater

-

Power Source:

-

Electric

-

Voltage:

-

0-380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

GRD

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

1 KG

-

Working Temperature Range:

-

800 - 1400 ℃

-

Service life:

-

Over 2000 hours

-

Application:

-

Sintering, melting

-

Size:

-

Cuztomized

-

Shape:

-

DB, ED, U, W, customized

-

MOQ:

-

1 Piece

-

Delivery time:

-

7-15 days

-

Packing:

-

Standard export wooden case

-

Certification:

-

CE, ISO

Product Description

Silicon carbide sic heating elements

are made from the high purity green hexagonal silicon carbide material. Make into blank according to a certain formula. Then through 2200 high temperature silicatization recrystallization sintering, non-metallic high temperature electric heating element is finished. The normal operating temperature in the oxidizing atmosphere

can reach 1450, and the continuous use can reach more than 2000 hours -3000 hours.

Compared with metal electric heating material, this kind of elements is characterized of high operating temperature,

anti-oxidization, anti-corrosion, long service life, little deformation, easy installation and maintenance. Because of these

advantages, SiC electric heating element is widely used in various high temperature electric furnaces and other heating devices, such as in the industries of magnet, ceramics, power metallurgy, glass, metallurgy and machinery, analysis test, semiconductor,science & research and so on.

Compared with metal electric heating material, this kind of elements is characterized of high operating temperature,

anti-oxidization, anti-corrosion, long service life, little deformation, easy installation and maintenance. Because of these

advantages, SiC electric heating element is widely used in various high temperature electric furnaces and other heating devices, such as in the industries of magnet, ceramics, power metallurgy, glass, metallurgy and machinery, analysis test, semiconductor,science & research and so on.

|

1

|

Withstands as high as 1600°C (surface temperature)

|

|

2

|

Generates high heat output per unit surface area, approximately 5-10 times than the output of Nichrome wire

|

|

3

|

High strength and excellent shock resistance

|

|

4

|

Heat source is free of noise and air pollution

|

|

5

|

Efficiently handle a wide range of products and atmospheres without any protection atmosphere

|

|

6

|

High operating temperature, anti-oxidization, anti-corrosion, long service life, little deformation, easy installation and maintenance

|

Direction for Using & Installing

Detailed Images

SiC electric heating elements can be customized as the drawings, which are widely used in various high temperature electric furnaces and other heating devices.

Specification

|

Specific Gravity

|

2.6~2.8g/cm³

|

Bend Strength

|

>300kg

|

|

Hardness

|

>9MOH'S

|

Tensile Strength

|

>150kg/cm³

|

|

Porosity Rate

|

<30%

|

Radiance

|

0.85

|

Shapes: ED type(rod shape), DB type(dumbbell shape),U type, W type (Three Phase shape), Solid rod type, SC type(single-spiral shape), SCR type(double-spiral shape),UX type(slot shape),3ED type, L type(bend shape) and 5 piece type (dual hot zone) or according to your requirement.

Diameter: 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25 inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) and so on.

When you place an order of rod type sic heating elements, please give following information:

OD: Outer Diameter;

HZ: Length Of Hot Zone;

CZ: Length Of Cold Zone;

OL: Total Length

Diameter: 8mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm, 25mm, 30mm, 31.7mm (1.25 inch), 35mm, 38.1mm (1.5 inch), 40mm, 44.4mm (1.75 inch) to 54mm (2.125 inch) and so on.

When you place an order of rod type sic heating elements, please give following information:

OD: Outer Diameter;

HZ: Length Of Hot Zone;

CZ: Length Of Cold Zone;

OL: Total Length

Order Sample:

ED(Rod)Shape: OD=54mm,HZ=1575mm,CZ=419mm, OL=2413mm, Resistance: 0.9

Specify as: ED, 54/1575/2413/0.90

ED(Rod)Shape: OD=54mm,HZ=1575mm,CZ=419mm, OL=2413mm, Resistance: 0.9

Specify as: ED, 54/1575/2413/0.90

Packing&Shipping

Silicon carbide sic heating elements are packed in export standard plywood case outside, lined with sponge and foam inside. It is also individually packed with buffer material. And then hang them by steel trapezes and springs outside to ensure the safety of the goods.

Related Products

Company Introduction

Henan Gurdoo Industry Co.,Ltd. is founded by engineers who have more than 20 years’ experience in research and production, which is specialized in manufacturing silicon carbide sic heating elements, MoSi2 heating elements, alumina ceramics, silicon carbide refractory, high temperature furnace and also can supply molybdenum and tungsten products, ceramic fiber insulation and quartz glass tube, etc.

Focusing on professional high temperature working field, we have the stable and efficient industrial production with ISO9001, CE, GB, CO, FTA certifications etc. All material & components adopt the qualified materials. 100% quality check and durable testing for every product before shipment will supply you high quality products and VIP service.

We have a well team-conscious, the ability of communication and coordination, work hard, meticulous and patience can afford the pressure of the work.

We provide cost efficient quality products for our customers, assisting them to gain competitive advantages are our major focus.

Focusing on professional high temperature working field, we have the stable and efficient industrial production with ISO9001, CE, GB, CO, FTA certifications etc. All material & components adopt the qualified materials. 100% quality check and durable testing for every product before shipment will supply you high quality products and VIP service.

We have a well team-conscious, the ability of communication and coordination, work hard, meticulous and patience can afford the pressure of the work.

We provide cost efficient quality products for our customers, assisting them to gain competitive advantages are our major focus.

After Sales Service

24 hours Service

1. Any inquiries will be replied professionally within 24hours.

2. Technical staff available for the technical assistance anytime.

3. Professional customization of furnace and project is offered.

4. Small MOQ, Fast delivery and competitive freight.

5. Also can help to purchase other products if you needed.

2. Technical staff available for the technical assistance anytime.

3. Professional customization of furnace and project is offered.

4. Small MOQ, Fast delivery and competitive freight.

5. Also can help to purchase other products if you needed.

FAQ

Q1. What information should we supply to get a quote?

Please offer the specification of silicon carbide sic heating elements, such as shape, dimension, quantity, application etc.

Q2. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application.

Then our technical staff will check and offer you the most suitable type or material.

Q3. How can we place an order?

You can contact any sale person by email, trade manager, skype, WhatsApp, WeChat and so on.

And more details of the products you supplied will be helpful to get the targeted responses.

Q4. How long our order can be finished?

A mass of semi-finished products and standard sizes are available in stock, and 10-30days for bulk production or customized

products.

Q5. What do you do on quality control?

For every batch, each step and finished products will be inspected when producing by QC department.

Q6. How can we get the sample?

Free samples can be supplied after communication, but freight is for your account.

Q7. Can you accept OEM/ODM?

Yes, your goods will be produced exactly according to your drawings.

Please offer the specification of silicon carbide sic heating elements, such as shape, dimension, quantity, application etc.

Q2. What type or material should we choose?

If you are not sure about the type/material needed, please kindly supply more details about working condition and application.

Then our technical staff will check and offer you the most suitable type or material.

Q3. How can we place an order?

You can contact any sale person by email, trade manager, skype, WhatsApp, WeChat and so on.

And more details of the products you supplied will be helpful to get the targeted responses.

Q4. How long our order can be finished?

A mass of semi-finished products and standard sizes are available in stock, and 10-30days for bulk production or customized

products.

Q5. What do you do on quality control?

For every batch, each step and finished products will be inspected when producing by QC department.

Q6. How can we get the sample?

Free samples can be supplied after communication, but freight is for your account.

Q7. Can you accept OEM/ODM?

Yes, your goods will be produced exactly according to your drawings.

Hot Searches