- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

QT

-

Voltage:

-

220V/380V

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

700 kg

-

Processing customization:

-

Yes

-

type:

-

Brick machine

-

Molding cycle:

-

35-45 (seconds)

-

Transmission mode:

-

Manual/conveyor belt

-

Excitation frequency:

-

1 (time/minute)

-

After-sales Service Provided:

-

1200(KN)

-

Vibration frequency:

-

50(hz)

-

Main vibration form:

-

Vibratory Electromechanical

-

Total power:

-

7.5(w)

-

purpose:

-

Paving and wall building

Quick Details

-

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

QT

-

Voltage:

-

220V/380V

-

Marketing Type:

-

New Product 2022

-

Weight (KG):

-

700 kg

-

Processing customization:

-

Yes

-

type:

-

Brick machine

-

Molding cycle:

-

35-45 (seconds)

-

Transmission mode:

-

Manual/conveyor belt

-

Excitation frequency:

-

1 (time/minute)

-

After-sales Service Provided:

-

1200(KN)

-

Vibration frequency:

-

50(hz)

-

Main vibration form:

-

Vibratory Electromechanical

-

Total power:

-

7.5(w)

-

purpose:

-

Paving and wall building

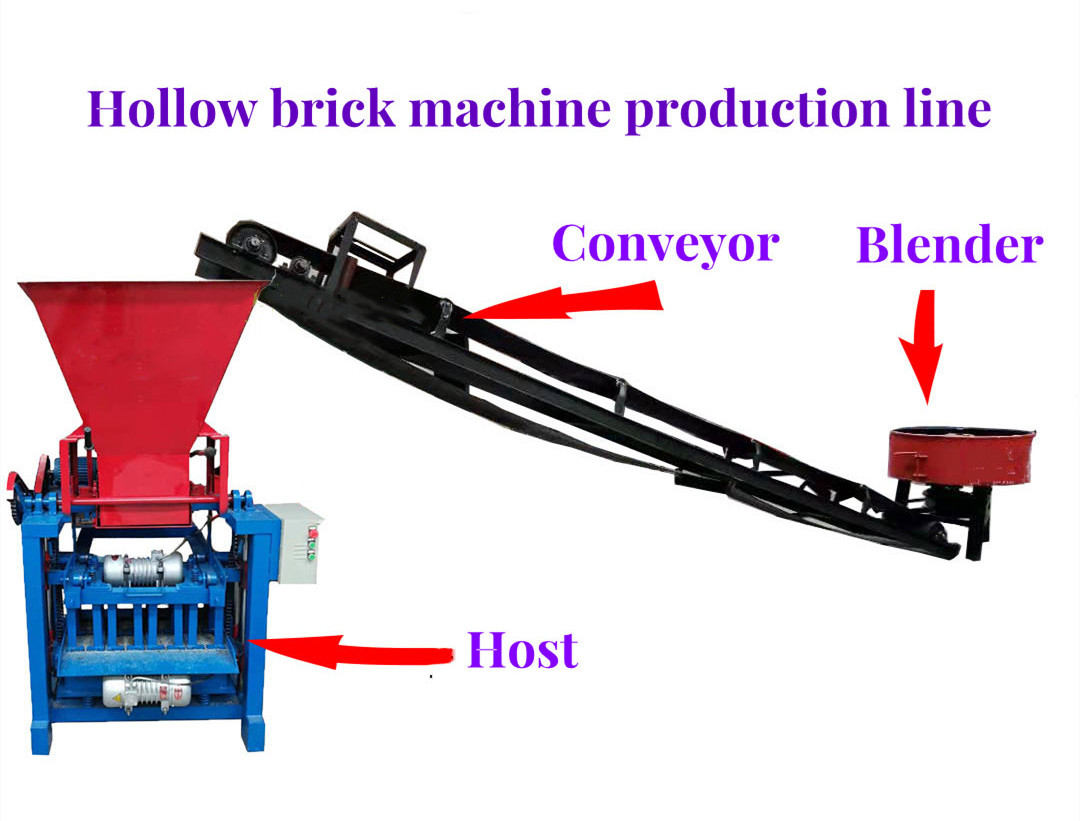

Product Description

Hot Sale automatic hollow cement paver moulding manual concrete block making machine price.

Performance:

This machine is easy to operate. It can replace various molds and produce hollow bricks and standard bricks of various specifications. It is a good machine for rural prosperity. It uses agricultural electric power and does not need a pallet. Two to eight blocks are produced each time. One person can produce them on the road.

Use method of unburned cement brick machine:

1. Check whether all parts of the machine are loose; Lubricating oil shall be added to the oil filling part to reduce mechanical friction and prolong service life.

2. After the power is turned on, press the mold lifting button to hang the ram; Overlap the mold box and the pressure head several times to check whether it is smooth.

3. Press the mold lowering button, drop the mold box onto the wooden pallet, push back the ram, and start feeding into the mold box, then open the lower vibration button to vibrate for 5-8 seconds, stop vibrating and add a little material, and scrape the excess material to the horizontal position of the mold box.

4. Pull back the ram to touch the baffle, and the hook under the plate will drop the ram. At the same time, turn on the upper and lower vibration switches. When the horizontal bars on the two half lead screws reach the position, turn off the upper and lower vibration buttons. Start the lifting button to hang the upper ram on the hook, and stop immediately when it reaches the position to avoid collision. The bricks and supporting plates can only be pulled out with a forklift after the hooks are firmly hung.

Structural principle and characteristics of cement unburned brick machine:

1.The 4-35 cement brick making machine adopts four column guidance and is equipped with a strong vibration motor. It uses a vibration table to conduct directional vertical vibration and upper mold pressurization vibration. With a small power, it can achieve strong vibration effect, so that all raw materials can flow and fill densely, greatly improving the production efficiency, and the bricks produced are uniform in density and high in strength.

2. The machine adopts upper mold pushing and pulling, manual scraping and brick discharging. The operation is convenient and flexible, and can be mastered quickly.

3. The machine body is made of large steel and special welding technology and materials, which is firm and shock resistant. The suspension and connection parts of the whole machine adopt "spring isolation technology" and directional vertical vibration technology, which reduce power loss, improve compactness, achieve good shock absorption effect, reduce die wear, and extend the working life of the die.

4. The wooden pallet is synchronous resonance with the mold during forming without impact, and its service life is more than twice that of similar products.

5. One machine can be used for many purposes, and different specifications of molds can be used to produce cement bricks of different specifications. The mold is easy to replace and maintain.

6. The pressure head can be moved longitudinally, which is convenient for feeding, maintenance and flushing. The gap between the presser foot and the mold box is small, the rough edge of the block is small, and the appearance is good.

Use raw materials

Application field

It can produce standard blocks, non-standard blocks, paving blocks, bearing blocks, non bearing blocks and light blocks. The surface of the block is complete, dense and beautiful.

Product size

|

Brick size

|

Block/time

|

Brick size

|

Block/time

|

|

400*200*200

|

4 pieces

|

390*140*190

|

5 pieces

|

|

390*190*190

|

4 pieces

|

390*120*190

|

6pieces

|

|

390*150*190

|

5 pieces

|

240*115*53

|

26pieces

|

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging serviceswill be provided.

Hot Searches