- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

3850*1300*1300mm, 3850*1300*1300mm

-

Weight (KG):

-

1800

-

Power (kW):

-

6

-

Applicable Industries:

-

Grinding machine

-

Table size:

-

1550*180mm

-

Max Grinding Length:

-

1600mm

-

Power:

-

6.0kw

-

Grinding speed:

-

17m/min

-

Wheel size:

-

200*100*32mm

-

Weight:

-

1800kg

-

Power of grinding head:

-

4kw

-

After-sales Service Provided:

-

Video technical support

Quick Details

-

Year:

-

2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SINOEURO

-

Voltage:

-

380V/415V

-

Dimension(L*W*H):

-

3850*1300*1300mm, 3850*1300*1300mm

-

Weight (KG):

-

1800

-

Power (kW):

-

6

-

Applicable Industries:

-

Grinding machine

-

Table size:

-

1550*180mm

-

Max Grinding Length:

-

1600mm

-

Power:

-

6.0kw

-

Grinding speed:

-

17m/min

-

Wheel size:

-

200*100*32mm

-

Weight:

-

1800kg

-

Power of grinding head:

-

4kw

-

After-sales Service Provided:

-

Video technical support

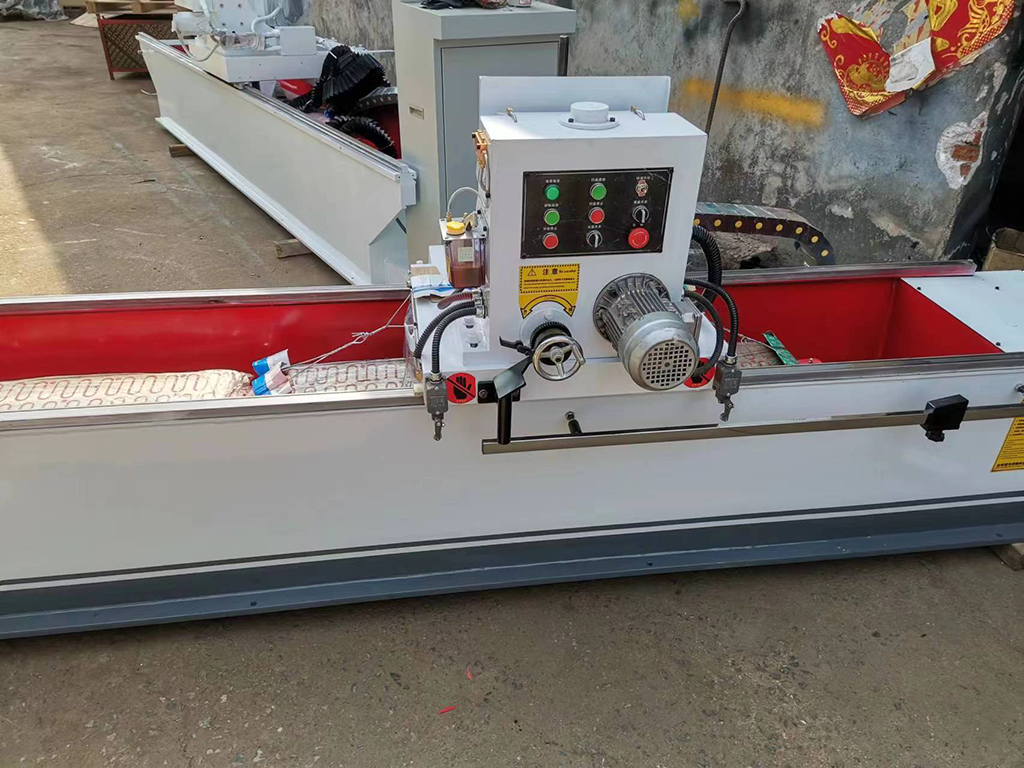

The knife grinder for veneer peeling blade is a

precision machine

designed to sharpen and maintain the blades used in veneer peeling. This machine is equipped with advanced features such as a

high-precision grinding wheel, automatic knife feed, and precise angle adjustment system

to ensure consistent and accurate sharpening results.

Specification

|

Name and Model

|

MZ6115

|

MZ7115

|

|

Maximum grinding length

|

1600mm

|

1600mm

|

|

Length * width

|

1550*180(200)mm

|

1550*180(200)mm

|

|

Adjustable angle of operating cutter table

|

±90°

|

±90°

|

|

Power of grinding head motor

|

3KW

|

5.5kw

|

|

Gross power

|

5.5KW

|

6kw

|

|

Reciprocating speed of grinding speed

|

14m/min

|

17m/min

|

|

External dimension

|

3000*1000*1200mm

|

3850*1300*1300mm

|

|

Total weight

|

1200kg

|

1800kg

|

|

Grinding head drive mode

|

Belt transimission

|

Belt transimission

|

Product Description

MZ electromagnetic full- automation cutter grinder

Suitable for:

Small-scale processing factory, blade manufacturer, hardware accessory factory, board processing factory, printing plant

...

Feature: 1. Adopts cycloidal pin gear speed reducer to ensure travelling stability, and greatly

improve the grinding quality and operational efficiency

.

2. The electromagnetic chuck is excellent in quality, durable and in line with national standard, which ensures less heat generation, great suction force and long service life.

3.

Water tank for knife sharpening to avoid sparks and to cool down the machine, helping to prolong its service life.

In addition to its advanced features, this machine is also designed with

safety and ease-of-use

in mind. Its intuitive controls and user-friendly design make it

easy to operate

, while safety features such as a protective shield and emergency stop button ensure the safety of the operator.

Details Images

Grinding head

The grinding head part of the machine tool

adopts rapid hoisting device

, which makes the replacement of the girnding wheel more convenient and rapid, improves the operational efficiency, and reduces labor intensity/The thickened ball screws inside work with the adjustable coppermade nuts to facilitate the adjustment of the axial clearance of the screw rods. The grinding head adopts the grinder motor of national standard and is resonable designed to improve the grinding precision and prolong the service life.

Electromagnetic chuck

Electric control panel

Product Use Range

With a powerful motor and durable construction, this machine is capable of handling

a wide range of blade sizes and types

, making it a versatile tool for any veneer peeling operation. Whether you need to sharpen new blades or maintain existing ones, this knife grinder is a reliable and efficient choice.

Hot Searches