- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v, 380 v

-

Power:

-

7500

-

Dimension(L*W*H):

-

1020mm*500mm*965mm

-

Weight (KG):

-

920

-

Name:

-

Steel upsetting machine

-

Motor power:

-

7.5KW

-

Machined rebar:

-

16-32 mm

-

Hydraulic pump:

-

McY14-1b

-

Maximum working pressure:

-

30MPa

-

Antiwear hydraulic oil:

-

68

-

Machine weight:

-

920Kg

-

Machine size:

-

1020*500*965mm

-

origin:

-

China

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

jiesheng

-

Machine Type:

-

Rebar upsetting machine

-

Voltage:

-

380v, 380 v

-

Power:

-

7500

-

Dimension(L*W*H):

-

1020mm*500mm*965mm

-

Weight (KG):

-

920

-

Name:

-

Steel upsetting machine

-

Motor power:

-

7.5KW

-

Machined rebar:

-

16-32 mm

-

Hydraulic pump:

-

McY14-1b

-

Maximum working pressure:

-

30MPa

-

Antiwear hydraulic oil:

-

68

-

Machine weight:

-

920Kg

-

Machine size:

-

1020*500*965mm

-

origin:

-

China

Products Description

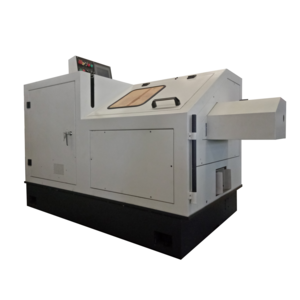

7.5KW hydraulic Rebar Thread Rolling Machine Screw Heading Machine Cold Heading Machine Metal Forging Machinery

Title goes here.

Adopting hydraulic system and electric structure, new product and new technology, just press on a power button, the overall upsetting work is completed at one time, high processing accuracy and quality assurance.

Rebar upsetting uses the principle of cold heading to make the plastic deformation of rebar end and increase the diameter by 4~6mm, and then process the thread. The actual cross-sectional area after processing the thread is larger than the original cross-sectional area of the bar, which greatly improves the tensile strength of the joint. This kind of upsetting threaded joint is tested by tensile test all broken in the base material, suitable for construction, road and bridge, high speed railway, power station with high requirements; simple operation, aspect

Detailed information

|

Name

|

Steel upsetting machine

|

|

Voltage

|

380 v

|

|

Motor power

|

7.5KW

|

|

Machined rebar

|

16-32 mm

|

|

Hydraulic pump

|

McY14-1b

|

|

Maximum working pressure

|

30MPa

|

|

Antiwear hydraulic oil

|

68

|

|

Machine weight

|

920Kg

|

|

Machine size

|

1020*500*965mm

|

pictrure

Contact

packing&shipping

FAQ

Are you manufacture?

Yes. We are one of leading manufacturers

Do you have Stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual

for punctual delivery.

(2) 20years production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad

situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to

discuss with him for all the problems and the way sames much times.

Yes. We are one of leading manufacturers

Do you have Stock productions to sell?

Yes,of course.But we also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual

for punctual delivery.

(2) 20years production experience. We have over 20 years experience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad

situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to

discuss with him for all the problems and the way sames much times.

Our service

1. 24 hours on line service, support Chinese, English, Spanish, French, German, Russian ,technical guidance.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Provide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Provide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.

Hot Searches