- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jian'en

-

Model Number:

-

customizable

-

Surface Treatment:

-

Vinyl Coated

-

Sample Time:

-

3-7 Days

-

Production Capacity:

-

8000tons/Month

-

Sample:

-

Avaiable

-

Package:

-

Customized

-

Port:

-

tianjin

Quick Details

-

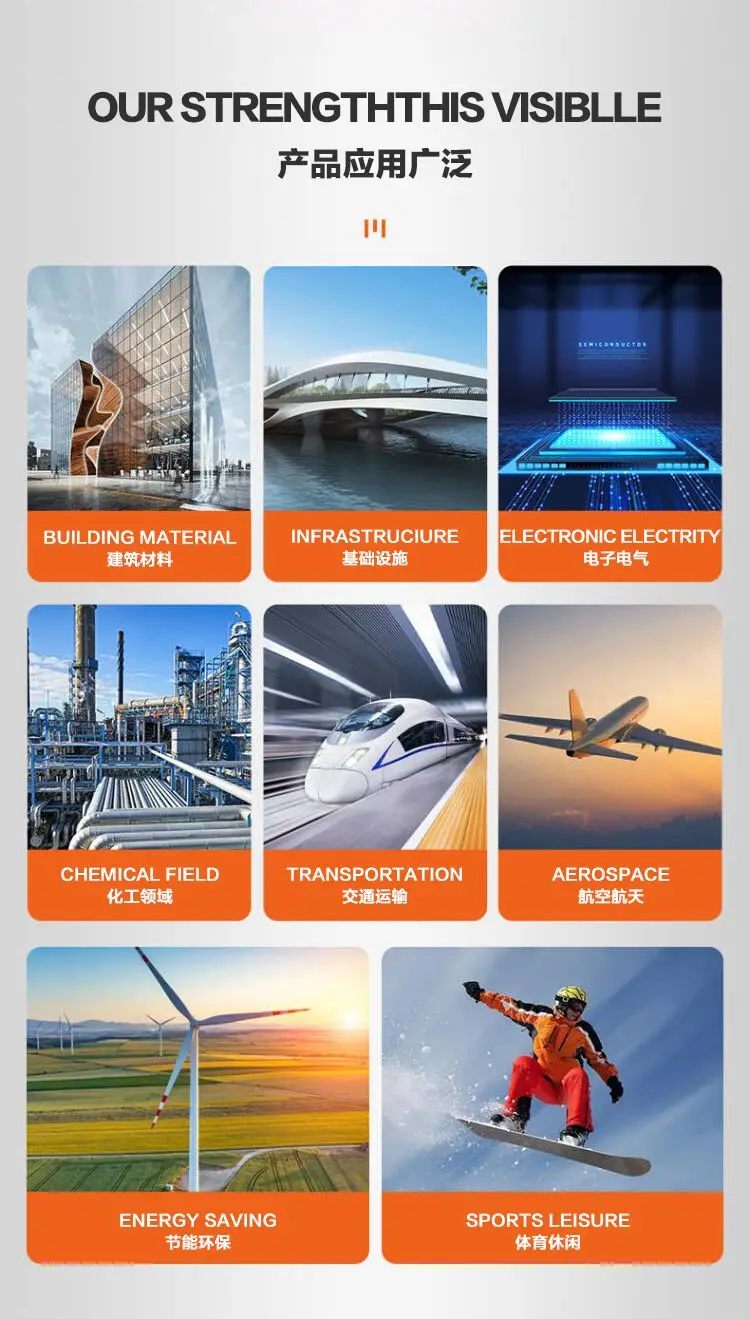

Application:

-

Industry/Construction/concrete, concrete

-

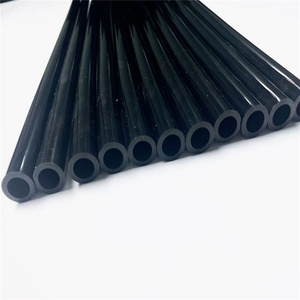

Technique:

-

Winding Filament Roving, reinforcing thermoplastics

-

Place of Origin:

-

Hebei, China, China

-

Brand Name:

-

Jian'en

-

Model Number:

-

customizable

-

Surface Treatment:

-

Vinyl Coated

-

Sample Time:

-

3-7 Days

-

Production Capacity:

-

8000tons/Month

-

Sample:

-

Avaiable

-

Package:

-

Customized

-

Port:

-

tianjin

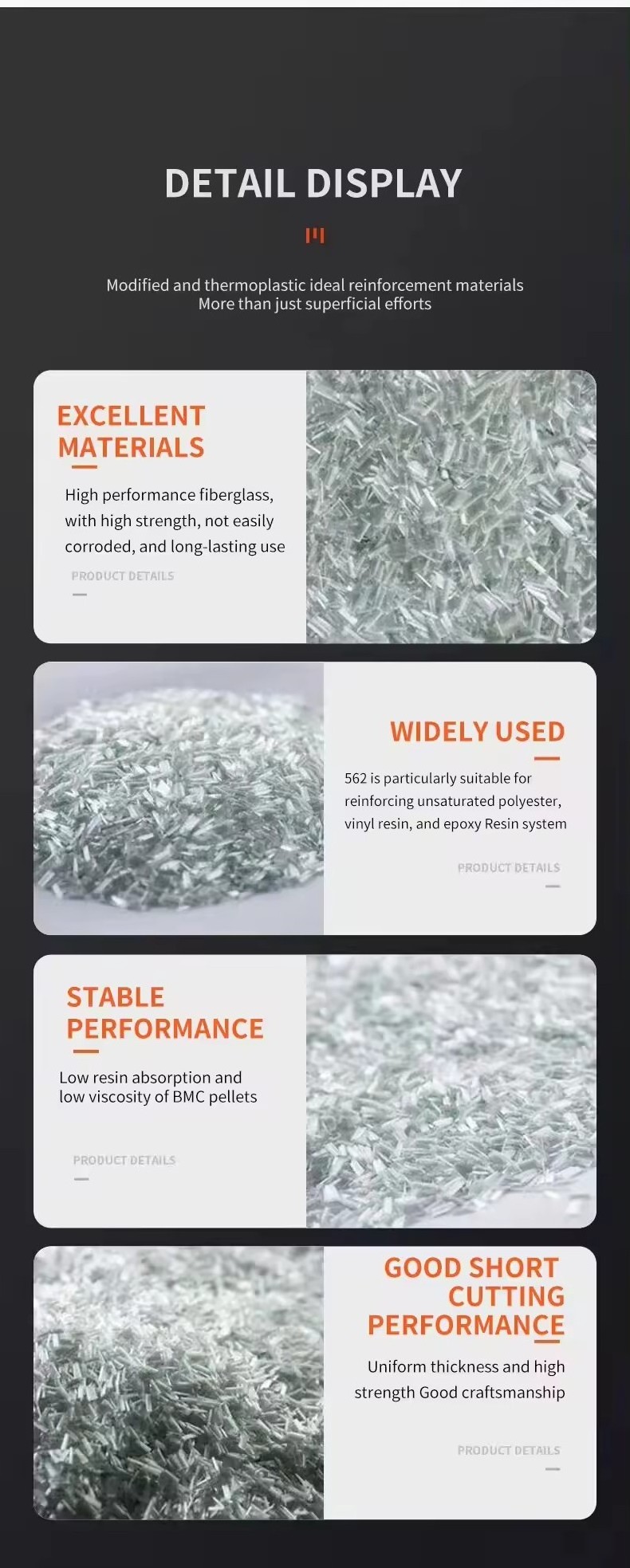

Product Description

Glass fibre

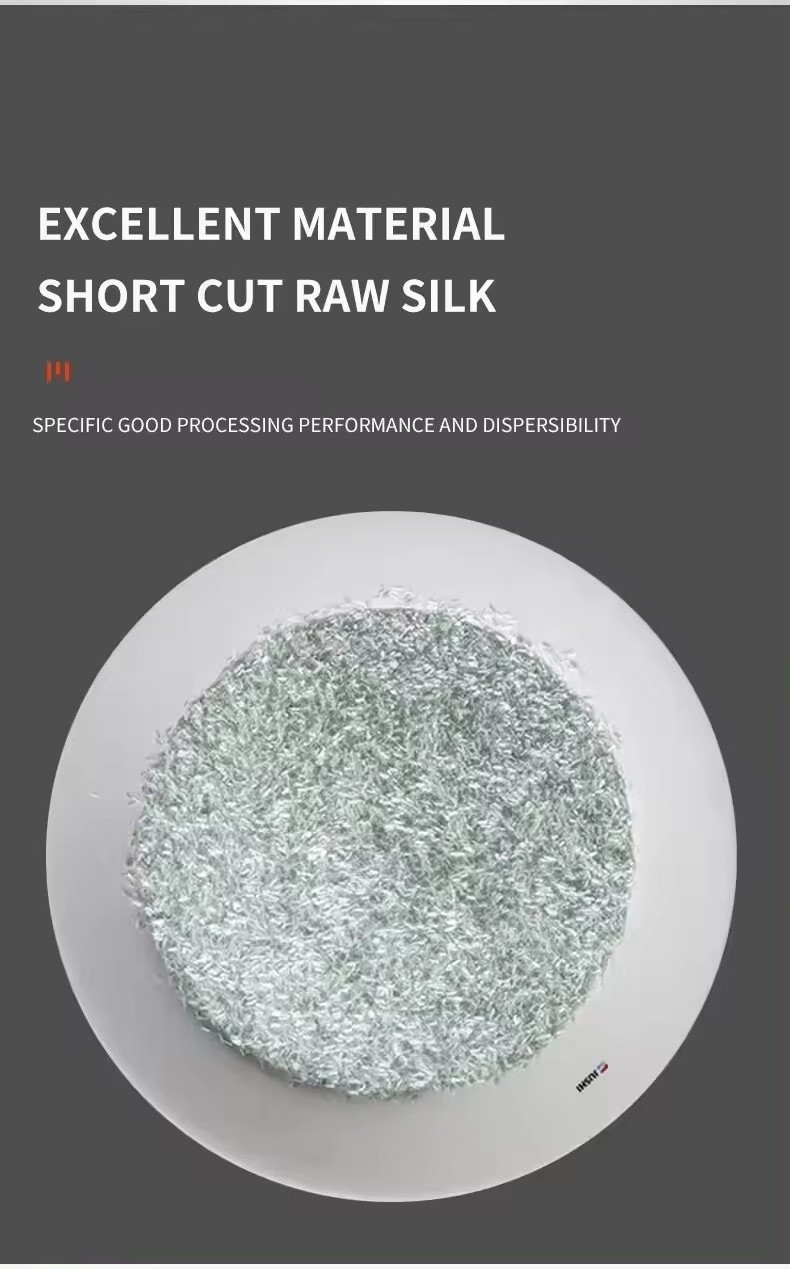

Fiberglass Chopped strand was the main raw material for Gypsum Board, Concrete Reinforcement, Cement Reinforcement and other Concrete/Gypsum Products. Fiberglass Chopped Strand is the new product for environmental protection property. It was widely used in the field of Construction Industry.

Fiberglass Chopped Strand was treated by silane coupling agent, which makes it has excellent dispersity and composition with other inorganic materials and resin for actual use.

Product characteristics:

1.Modest water content.Good flowability, even distribution in finished products.

2.Quickly wet-out, high mechanical strength of finished products.Best cost performance.

3.Good bundling: ensure that the product does not fluff and ball in transit.

4. Good dispersibility: good dispersion makes the fibers evenly dispersed when mixed with cement mortar.

5. Excellent physical and chemical properties: it can significantly improve the strength of cement products.

Specification

|

Items

|

Standard

|

|

Product Name

|

GLASS FIBER

|

|

Length

|

12mm,18mm,19mm, or Customized

|

|

Diameter

|

3-15μm

|

|

Tensile strength

|

1700Mpa

|

|

Elongation

|

3-4%

|

|

Alkali-base resistance

|

strong

|

|

Feature

|

Excellent Tensile

|

Prouduct Application

1. On-site construction and pre-mixing method to make exterior wall panels, permanent formwork, wall mortar covering.

2. Prefabricated bridge beams, building support columns, Roman columns to prevent surface cracking.

3. Production of GRC architectural details, GRC exterior wall hanging panels, GRC garden landscape products, GRC lightweight

partition panels, GRC insulation panels, ventilation ducts, permanent tubular mandrels, permanent formwork,industrial building roofing components, sound barriers, Self-supporting floors, irrigation channels, etc.

1. On-site construction and pre-mixing method to make exterior wall panels, permanent formwork, wall mortar covering.

2. Prefabricated bridge beams, building support columns, Roman columns to prevent surface cracking.

3. Production of GRC architectural details, GRC exterior wall hanging panels, GRC garden landscape products, GRC lightweight

partition panels, GRC insulation panels, ventilation ducts, permanent tubular mandrels, permanent formwork,industrial building roofing components, sound barriers, Self-supporting floors, irrigation channels, etc.

Hot Searches