- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dongfang

-

Voltage:

-

380V (voltage can be customized)

-

Weight:

-

800kg

-

Dimension(L*W*H):

-

1600mm*1200mm*1400mm

-

Name:

-

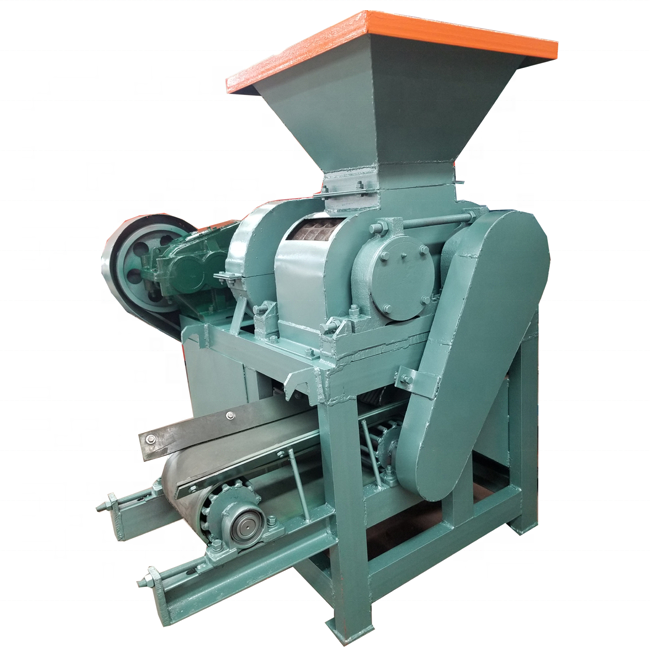

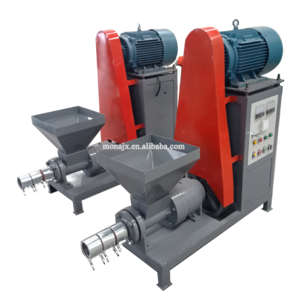

charcoal briquette press machine

-

Application:

-

Cooking/BBQ/Roast meat

-

Color:

-

Green Red Blue Yellow Orange

-

Mositure content:

-

15%

-

Raw material:

-

Coal powder or Charcoal powder

-

Briquette shape:

-

round ,cubic,oval,pillow

-

Certification:

-

ISO CE

Quick Details

-

Warranty:

-

12 Months

-

Core Components:

-

shaft

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dongfang

-

Voltage:

-

380V (voltage can be customized)

-

Weight:

-

800kg

-

Dimension(L*W*H):

-

1600mm*1200mm*1400mm

-

Name:

-

charcoal briquette press machine

-

Application:

-

Cooking/BBQ/Roast meat

-

Color:

-

Green Red Blue Yellow Orange

-

Mositure content:

-

15%

-

Raw material:

-

Coal powder or Charcoal powder

-

Briquette shape:

-

round ,cubic,oval,pillow

-

Certification:

-

ISO CE

Product Description

Coal briquette making production line can be used to suppress various po wders, scrap, waste residue such as pulverized coal, iron powder, coking coal, aluminum ash, iron filings, iron oxide scale, carbon dust, powdered carbon, slag, gypsum, gangue, sludge, kaolin, active carbon, coke breeze and so on. It can press the coal dust, charcoal powder and carbon black to different shapes,The final briquettes shapes can be egg shape, round shape, oval shape, square shape, pillow shape, or any other shapes according to your requirements.There are many different kinds of molds,so we also can make molds according to your needs.

We can design more special shapes for you.

Coal briquetting machines and coal briquette machines are widely used in refractory, powder plant, metallurgical, chemical engineering, energy, transportation, heating and other industries.

Technical Parameter

Detailed Images

Working principle of briquette shaping machine

This series of small briquette shaping machine will pass the power on to the two pressure roller through the reducer.The two sides and roll rotation, in both the rotating roll,Natural materials to enter the ballroll mode, with the roll rotation, material pressure on a small become larger, When the material to the two rollers rotating line contact point, the pressure of materials has reached the peak. Tremendous pressure in the role of line, the materials become a finished product from the powder ball.