It is better than sealing by inner heating machine . no need pre-heating .

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 50Hz/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SZHX

-

Dimension(L*W*H):

-

1630x1380x1600mm

-

Weight:

-

450 KG

-

Use For:

-

Sunscreen Block Base Cream Plastic Tube Filling Machine

-

Frequency:

-

20KHZ

-

Date coding:

-

one set in free charge

-

After wooden packing:

-

380KGS

-

Max.Tube length:

-

10-250mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Over look:

-

stainless steel body

-

Sealing Dia:

-

5-50mm

-

Product name:

-

Sealing Machine

Quick Details

-

Machinery Capacity:

-

22-28 pcs/min

-

Packaging Material:

-

Plastic, Metal, Composite

-

Filling Material:

-

Other, Water, Oil, Paste, Liquid, Gel, Cream

-

Filling Accuracy:

-

±1%

-

Voltage:

-

220V 50Hz/60Hz

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

SZHX

-

Dimension(L*W*H):

-

1630x1380x1600mm

-

Weight:

-

450 KG

-

Use For:

-

Sunscreen Block Base Cream Plastic Tube Filling Machine

-

Frequency:

-

20KHZ

-

Date coding:

-

one set in free charge

-

After wooden packing:

-

380KGS

-

Max.Tube length:

-

10-250mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Over look:

-

stainless steel body

-

Sealing Dia:

-

5-50mm

-

Product name:

-

Sealing Machine

Products Description

HX-009 FULLY AUTOMATIC ULTRASONIC TUBE FILLING AND SEALING MACHINE

Application of the Cosmetic Cream Tube Filling Sealing Machine:

Mainly Packaging the liquid or paste in small sachet at high speed, such as shampoo, lotion, hand washing, liquid soap,liquid

flavors, juice, oil, jam, honey for the tubes filing and sealing machine etc.

Mainly Packaging the liquid or paste in small sachet at high speed, such as shampoo, lotion, hand washing, liquid soap,liquid

flavors, juice, oil, jam, honey for the tubes filing and sealing machine etc.

|

Model

|

HX-009

|

|

Frequency

|

20kHz

|

|

Power

|

2600W

|

|

Power Supply

|

AC110V or AC220V single phase

|

|

Filling Range

|

A: 6-60ml B: 10-120ml C: 25-250ml D: 50-500ml

|

|

Filling Accuracy

|

±1%

|

|

Capacity

|

18-28tubes/min

|

|

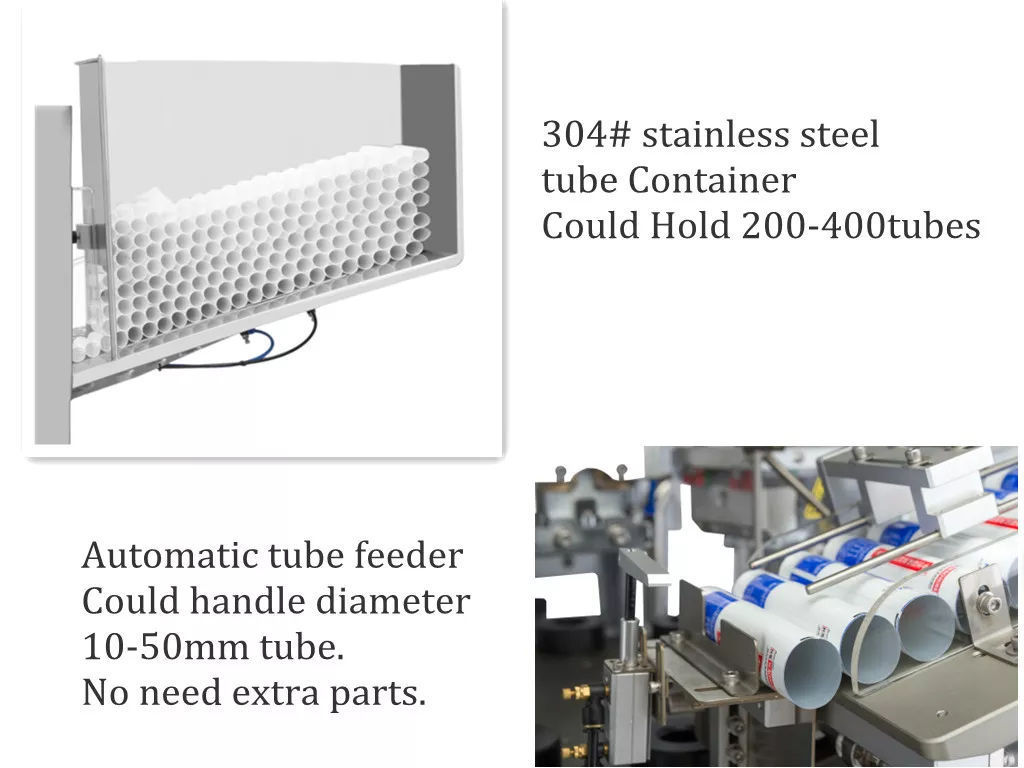

Tube Dia.

|

13-50mm

|

|

Tube Height

|

50-250mm

|

|

Air Pressure

|

0.6MPa

|

|

Air Consumption

|

0.35m³/min

|

|

Dimension

|

1630*1300*1580mm

|

|

N.W.

|

530kgs

|

WHAT IS ULTRASONIC SEALING ?

With ultrasonic sealing the inside seal area of the tube is heated by high frequency friction produced by an ultrasonic horn , the tube then clamped against the anvil and cooled to form tube seal.

ABL (Aluminum plastic tube )

Plastic tube

5 layers tube

Details Images

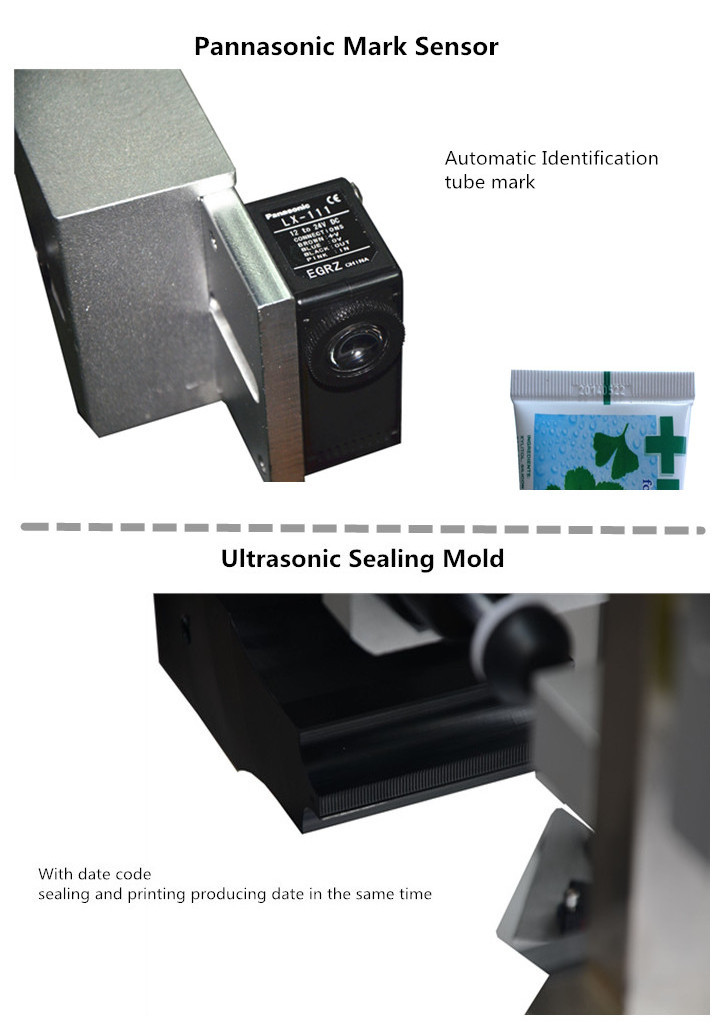

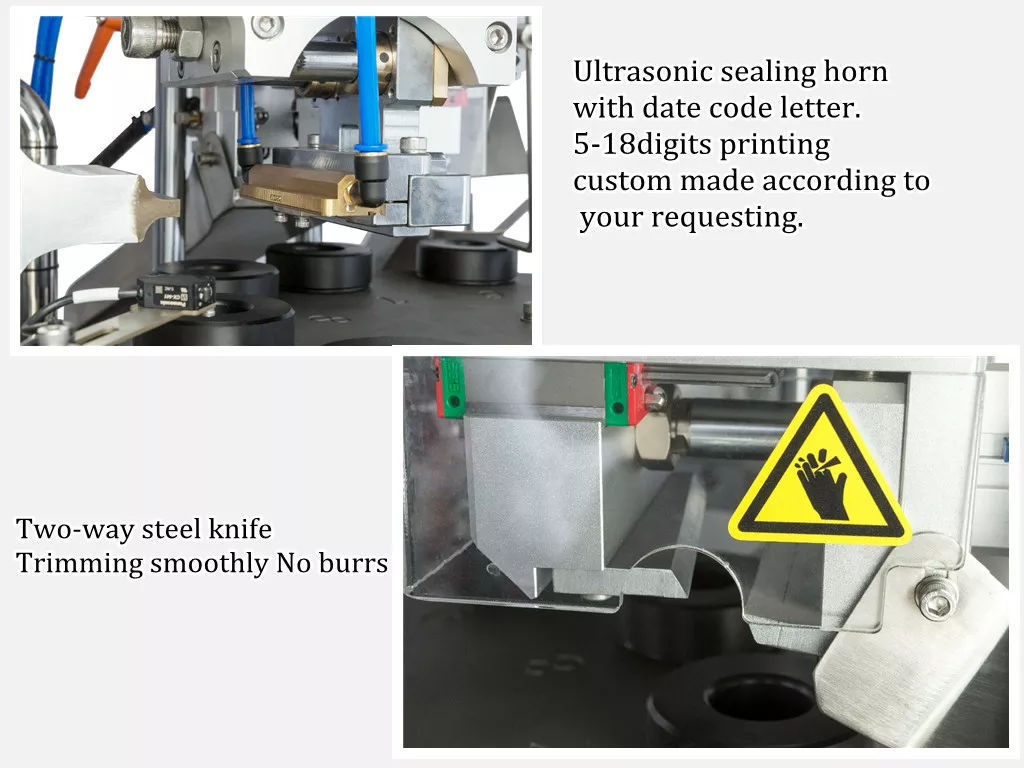

SPECIAL SHAPE CUTTING

FEATURE

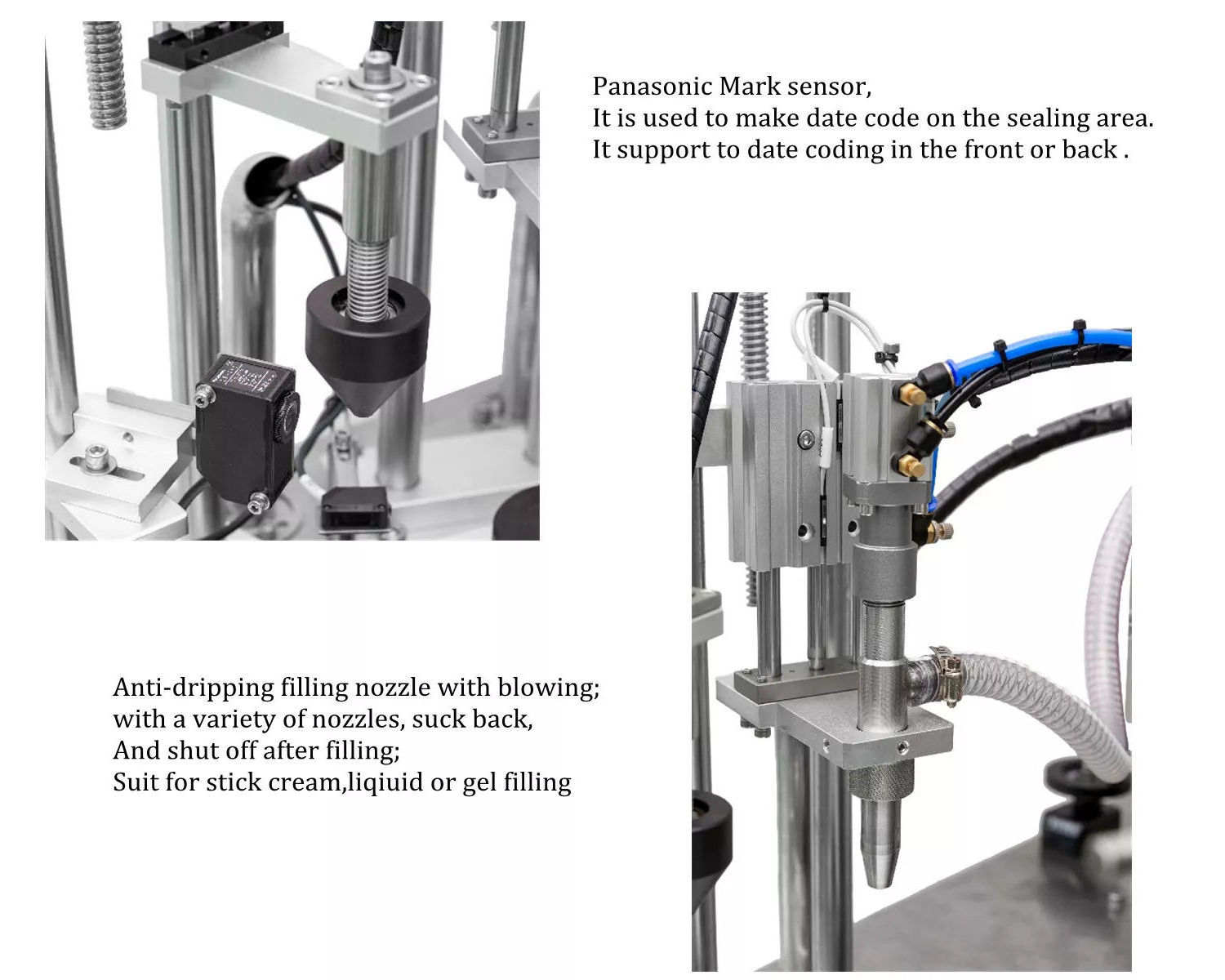

* Machine could automatically finish tube feeding , registration mark identifying, filling , sealing with date coding,end trimming , tube out feeding, fully automatic , save labor cost and lower production cost.

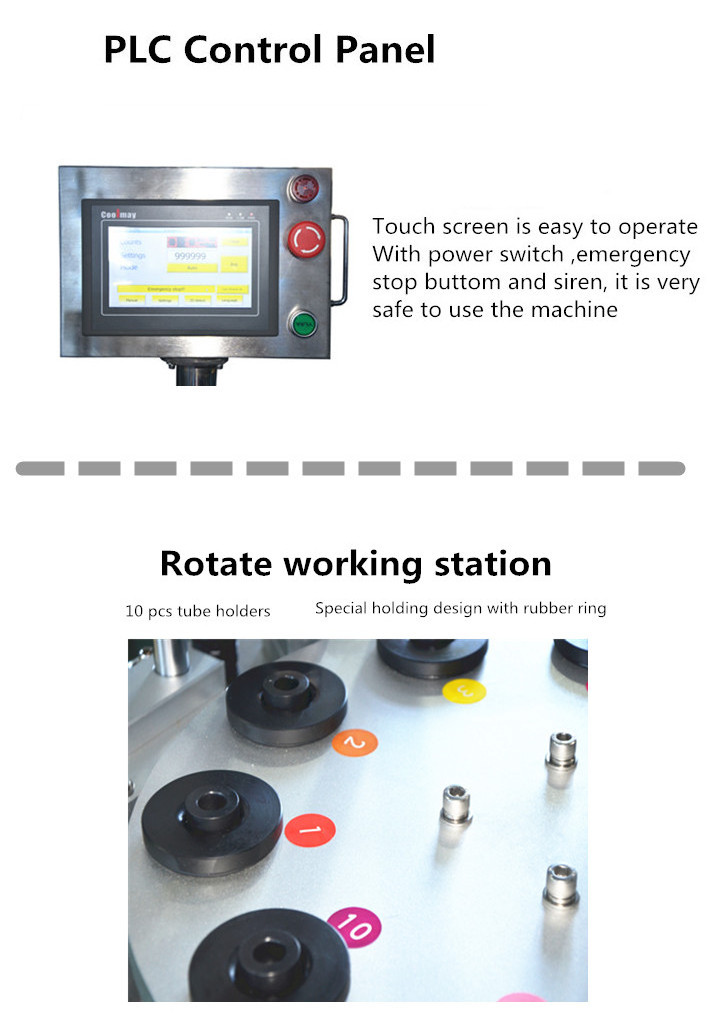

* Cam indexing system could position precisely for ten working stations.

*Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

* Independent R &D for digital ultrasonic automatic tracking electrical control box, no need manual adju st the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

* PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

* Made of 304 stainless Steel, acid and alkali resistance, corrosion resistance.

*No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

Hot Searches