- Product Details

- {{item.text}}

Quick Details

-

Center Height (mm):

-

850 mm

-

Max.Transformer Capacity(kVA):

-

1600 kVA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saber tooth tiger CNC

-

Motor Power (kw):

-

4

-

Weight (KG):

-

1000

-

Dimension(L*W*H):

-

2700mm*800mm*1300mm

-

Wire Diameter Range (mm):

-

0.3 - 5 mm

-

Name:

-

Electric Motor Coil Spooling Machine

-

Application:

-

Winding Coil

-

Product name:

-

Transformer Coil Winding Machine

-

Keyword:

-

Automatic Motor Wire Winding Machine

-

Function:

-

Coil Winding Coil Winding Tool

-

Used for:

-

High Frequency Transformer

-

Winding machine Type:

-

Bobbin Winding Machine

-

Usage:

-

Coil Wire Winding

-

Wire type:

-

Enamel Copper Wire

-

Certification:

-

CE ISO

Quick Details

-

Max. Load (KG):

-

1000 KG

-

Coil Type:

-

high and low transformer coil

-

Length of Axis (mm):

-

1600 mm

-

Center Height (mm):

-

850 mm

-

Max.Transformer Capacity(kVA):

-

1600 kVA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Saber tooth tiger CNC

-

Motor Power (kw):

-

4

-

Weight (KG):

-

1000

-

Dimension(L*W*H):

-

2700mm*800mm*1300mm

-

Wire Diameter Range (mm):

-

0.3 - 5 mm

-

Name:

-

Electric Motor Coil Spooling Machine

-

Application:

-

Winding Coil

-

Product name:

-

Transformer Coil Winding Machine

-

Keyword:

-

Automatic Motor Wire Winding Machine

-

Function:

-

Coil Winding Coil Winding Tool

-

Used for:

-

High Frequency Transformer

-

Winding machine Type:

-

Bobbin Winding Machine

-

Usage:

-

Coil Wire Winding

-

Wire type:

-

Enamel Copper Wire

-

Certification:

-

CE ISO

Products Description

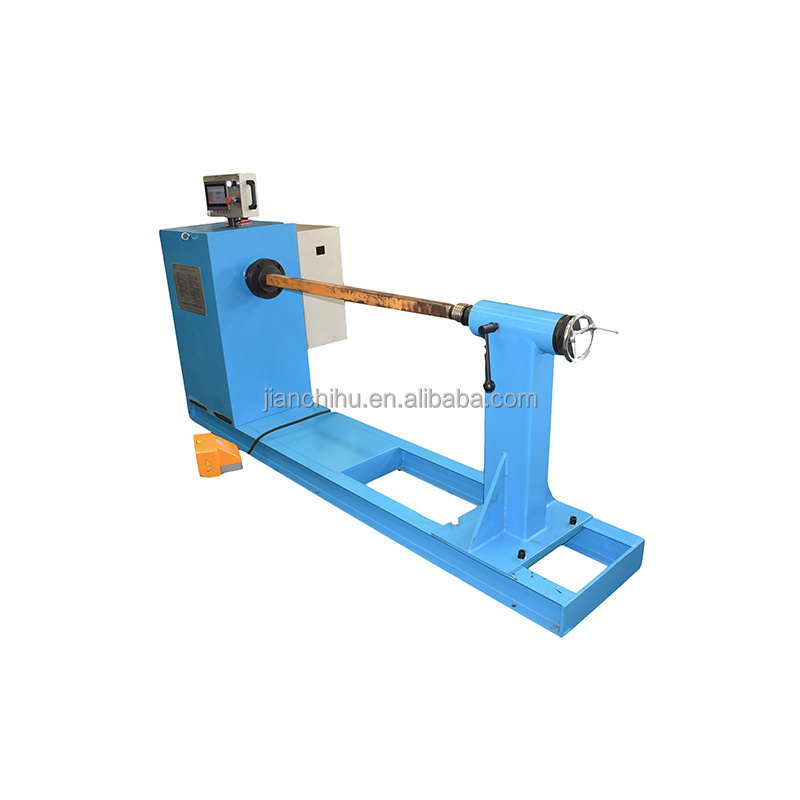

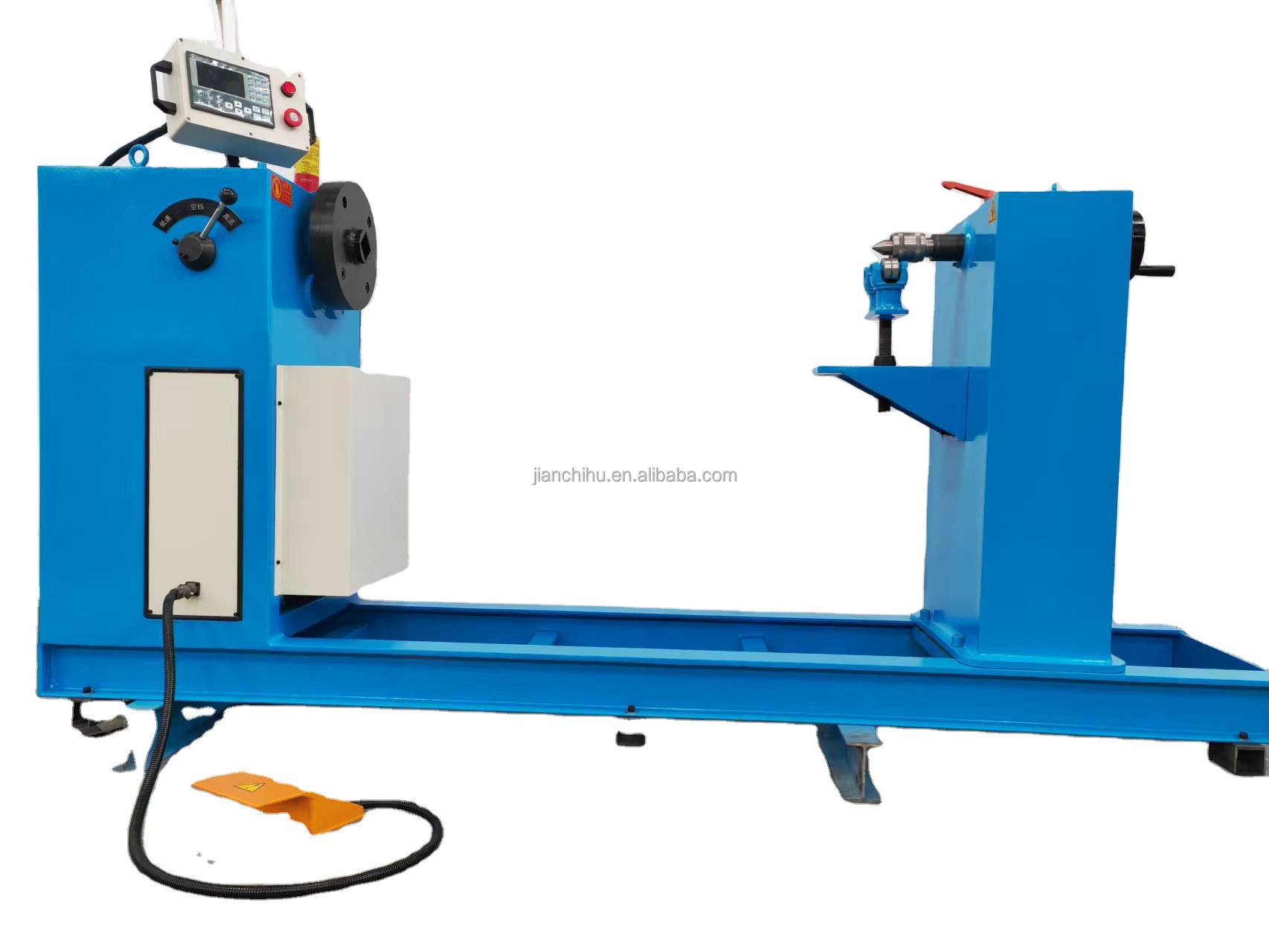

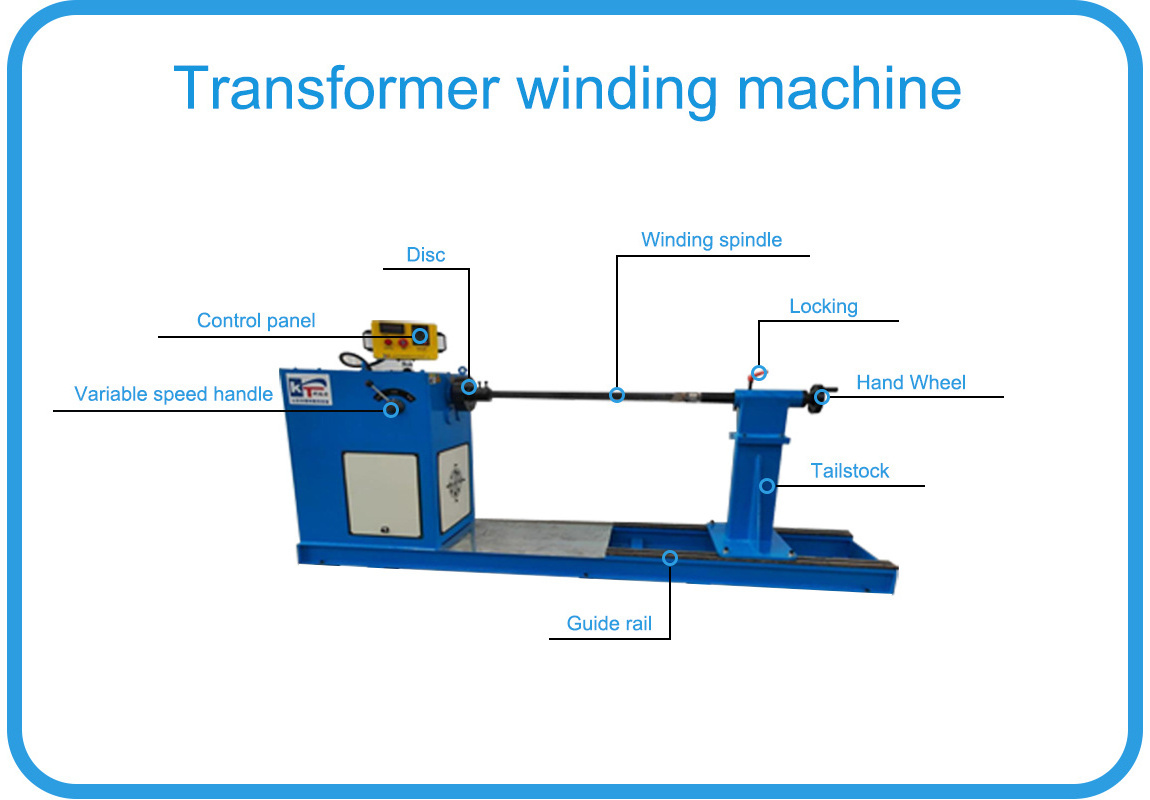

The winding machine is composed of main box, guide rail, rear tailstock and electrical control.The machine is suitable for winding high and low voltage

coils.Support customization of multiple specifications

Product Details

Counter

CNC screen

The winding machine adopts double speed regulation,mechanical speed regulation and frequency conversion speed regulator to realize stepless speed regulation.the number of turns can be set through the counter or the numerical control key screen(optional) to stop automatically.

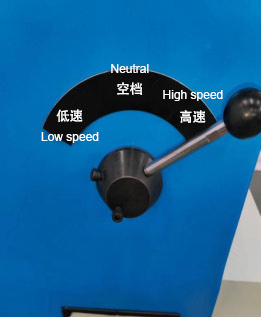

The double gear in the gearbox is moved by the speed change handle to realize the high,empty and low speed changes of the main shaft.(ONLY HIGH AND LOW GEAR MODEL HAVE THIS FUNCTION)

By rotating the hand wheel,the live center can be extended or returned,which is convenient to move the mold up and down,and improve the strength.

Equipped with an automatic brake device to prevent backing up when winding stops.

The tailstock can be moved axially on the guide rail of the base manually to meet the needs of different length linear dies.

Support preset the number of coil turns and control the positive inversion; the high precision encoder can count the positive and negative,and has the function of power-off memory.

The locking handle can lock the top roller, tighten the winding mold, and support its weight.

The disc plays the role of fixing the winding die and transmitting torque.

Electronic control system: The electronic control system is composed of electric control cabinet, frequency converter,counter,high precision encoder and other electrical appliances.

Product Paramenters

|

Parameters

|

RX-1T winding machine

|

RX-2T winding machine

|

RX-3T winding machine

|

|

Central height

|

850mm

|

900mm

|

1000mm

|

|

Disc diameter

|

Φ200 mm

|

Φ300 mm

|

Φ400 mm

|

|

Tailstock adjustment range

|

200-1600mm

|

200-1600mm

|

200-2000mm

|

|

Max torque of high and low speed type

|

1300N.M

|

1900N.M

|

2500N.M

|

|

Max torque of ordinary model

|

800N.M

|

1500N.M

|

1500N.M

|

|

Motor power

|

4KW

|

5.5KW

|

7.5KW

|

|

Counting accuracy

|

Counter:0.1circle

CNC panel:0.01circle

|

Counter:0.1circle

CNC panel:0.01circle

|

Counter:0.1circle

CNC panel:0.01circle

|

|

Speed range of High and low speed type

|

Low:0-30r/min

High:0-180 r/min

|

Low:0-30r/min

High:0-120 r/min

|

Low:0-20r/min

High:0-80 r/min

|

|

Speed range of ordinary models

|

0-140 r/min

|

0-70 r/min

|

0-60 r/min

|

|

Load capacity

|

1000KG

|

2000KG

|

3000KG

|

|

Dimensions

|

2700mm*800mm*1300mm

|

2850mm*1000mm*1400mm

|

3250mm*1100mm*1500mm

|

Support customization according to customer requirements.

Why Choose Us

Product packaging

Hot Searches