- Product Details

- {{item.text}}

Quick Details

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AJflying

-

Model Number:

-

SFP plywood formwork

-

Type:

-

Plywoods

-

NAME:

-

plywood formwork

-

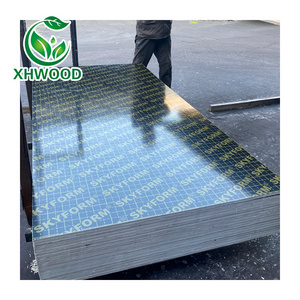

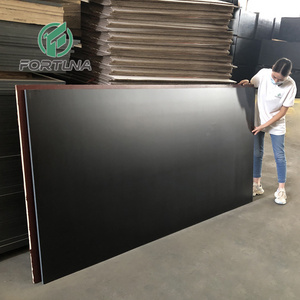

FILM TYPE:

-

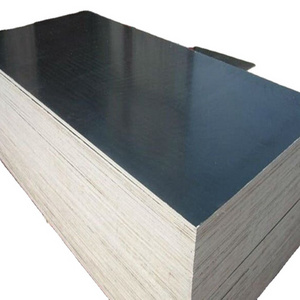

Brown and black film in glossy, matt, and mesh finish

-

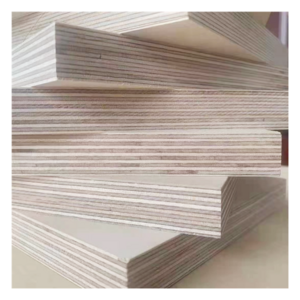

CORE SPECIES:

-

Poplar, Eucalyptus

-

SIZE(mm):

-

220x2440(4'x8'), 1250x2500, 915x2135(3'x7'), 1525x3050(5'x 10')

-

THICKNESS:

-

6.0mm-27mm

-

GLUE:

-

WBP phenolic, WBP, MR

-

Certification:

-

CE,ISO

-

name:

-

Plywood

-

keyword:

-

plywood formwork

Quick Details

-

Warranty:

-

1 Year

-

Project Solution Capability:

-

Others

-

Application:

-

School

-

Formaldehyde Emission Standards:

-

E1

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

AJflying

-

Model Number:

-

SFP plywood formwork

-

Type:

-

Plywoods

-

NAME:

-

plywood formwork

-

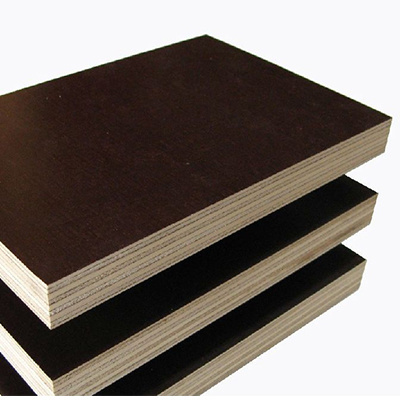

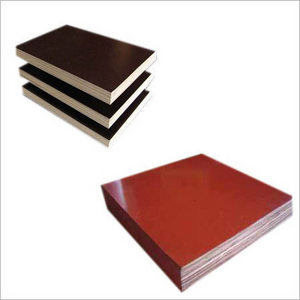

FILM TYPE:

-

Brown and black film in glossy, matt, and mesh finish

-

CORE SPECIES:

-

Poplar, Eucalyptus

-

SIZE(mm):

-

220x2440(4'x8'), 1250x2500, 915x2135(3'x7'), 1525x3050(5'x 10')

-

THICKNESS:

-

6.0mm-27mm

-

GLUE:

-

WBP phenolic, WBP, MR

-

Certification:

-

CE,ISO

-

name:

-

Plywood

-

keyword:

-

plywood formwork

After more than 30 years of experience, we have formed a complete one-stop industrial chain of steel products. The use of 3 advanced automatic welding machines has increased our daily production capacity to 50 tons per day, and we can produce 3,000 sets of steel scaffolding within 5 days. The automatic welding machine 100% guarantees that our products are completely welded, which is the most important load-bearing capacity of scaffolding. Users will not have load-bearing accidents when using scaffolding.

Product Features

building film faced plywood 18mm column wall pvc plywood formwork sheet for construction

|

Sample custom

|

5-7 days

|

|

Delivery date

|

20 days

|

|

Logo

|

Support oem

|

|

size

|

size

|

Regular Size

At the same time, we will use a sanding machine to grind the welding surface, which enhances the fatigue resistance of the metal, and the product is not easy to crack. We have different surface treatment production lines, the first one is powder coating. Each powder coating equipment can finish 10-20 tons per day. The powder coating is 100-300μm, the quality assurance is 5-10 years, and the second is galvanized surface treatment. Galvanized products are very durable and stable and can resist rust for 20 years.

Inspection Report

We are a quality inspection team with more than 30 years of experience. Through layer-by-layer screening and testing, we ensure the high-quality production of our scaffolding. The purpose of our quality inspection is 0 customer complaints and 100% customer service.

Buyer Show & Feedback

Project

Visit Client

Factory

Hot Searches