1.

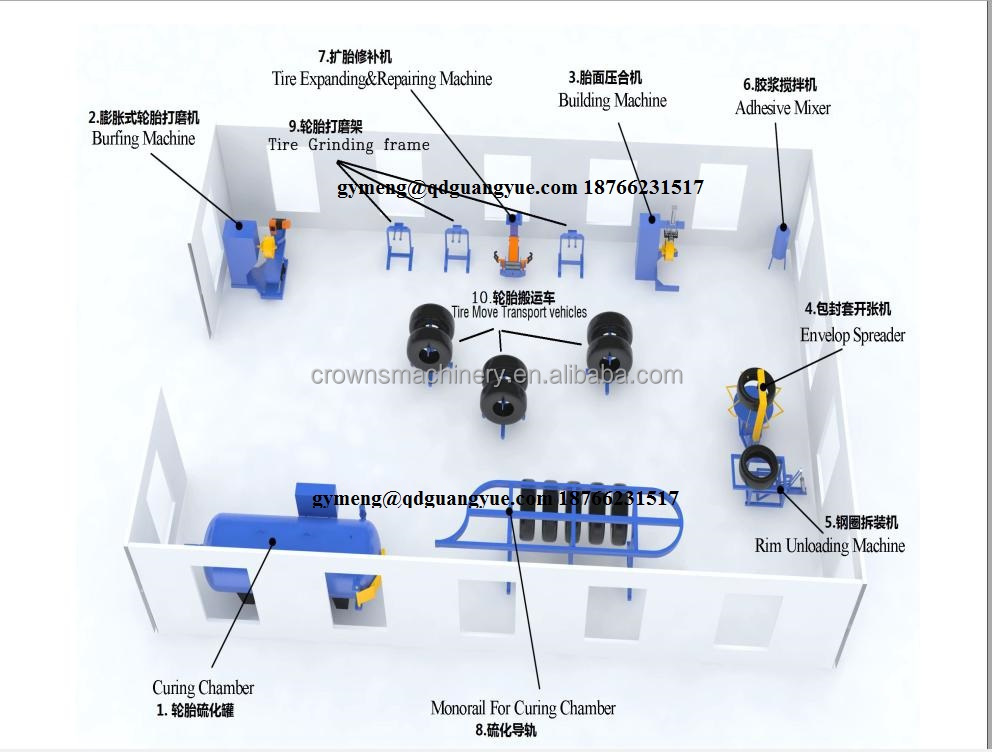

check out

Make sure the used tire casing can be accepted for retreading, or rejection.

2)

Buffing

Buffing tire casing, buffing the worn tread rubber..

3)

Planing

Remove all embedded objects in the casing, make sure the tire surface clean and solid, suitable for retreading.

4)

Use glue gun

Use glue gun to spray a thin layer of concentrated liquid cement in the repair tire casings.

5)

Glue filling

Fill in the repair cementing in the tire wound.

6)

Apply the tread rubber

Apply the cushion gum between the tread rubber and the casing, as the bonding layer. As a new layer , the intensive precure tread rubber is forming in the tire casings

7)

Assemble envelop

A special envelop is used to package the tires, ensure the tire casing and precure tread rubber successfully bond together

8)

Curing

This is a process of applying the new tread rubber to the prepared tire casings, then put into curing chamber, in a certain pressure and temperature after a period of correct time curing, the cushion rubber layer will adhere tight to the tire casings.

9)

Final inspection

Make sure all the recap been checked carefully, to ensure the safety and unharmed appearance of recycling products which sell to customers.

10)

Everything looks "like new"

Now, end product! Safe and durable, is equally matched with the new tire. And ready to hit the road

!