- Product Details

- {{item.text}}

Quick Details

-

Forming Time:

-

1000mm/min

-

Welding Mode:

-

butt welding

-

Welding Diameter:

-

250-3000mm

-

Use:

-

LPG Cylinder LNG Cylinder Pressure Vessel welding machine

-

Voltage:

-

220v, 380v or customised

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tank Circumferential lathe welder:

-

tank welding machine, welding lathe

-

type:

-

TIG, MIG, TIG+MIG, Plasma

-

Welding material:

-

stainless steel, carbon steel

-

Working mode:

-

Auto circumferential lathe welder with PLC control

-

Length of Material:

-

10-3000mm, could be customized

-

Diamter range of tank:

-

dia =250-3000mm, customized

-

Welding Thickness:

-

0.8-10mm, customized

-

MOQ:

-

1 set

-

Weight:

-

500KG

-

Power:

-

3kw

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

TOPSUN

-

Model Number:

-

MIG inverter welding machine

-

Forming Time:

-

1000mm/min

-

Welding Mode:

-

butt welding

-

Welding Diameter:

-

250-3000mm

-

Use:

-

LPG Cylinder LNG Cylinder Pressure Vessel welding machine

-

Voltage:

-

220v, 380v or customised

-

Warranty:

-

1 year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Tank Circumferential lathe welder:

-

tank welding machine, welding lathe

-

type:

-

TIG, MIG, TIG+MIG, Plasma

-

Welding material:

-

stainless steel, carbon steel

-

Working mode:

-

Auto circumferential lathe welder with PLC control

-

Length of Material:

-

10-3000mm, could be customized

-

Diamter range of tank:

-

dia =250-3000mm, customized

-

Welding Thickness:

-

0.8-10mm, customized

-

MOQ:

-

1 set

-

Weight:

-

500KG

-

Power:

-

3kw

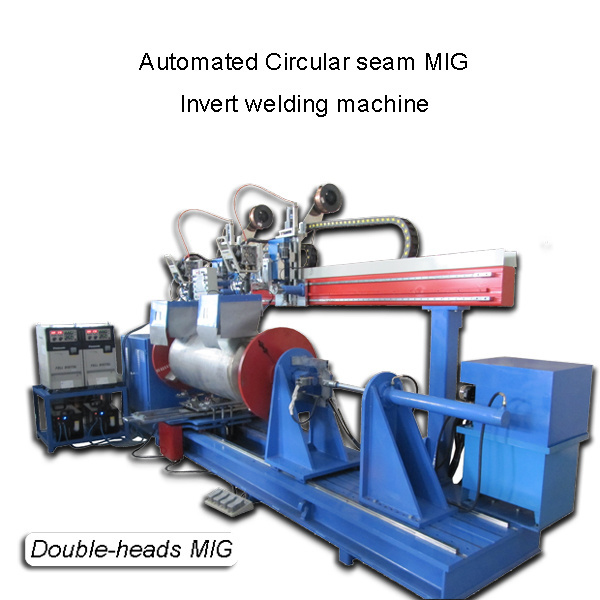

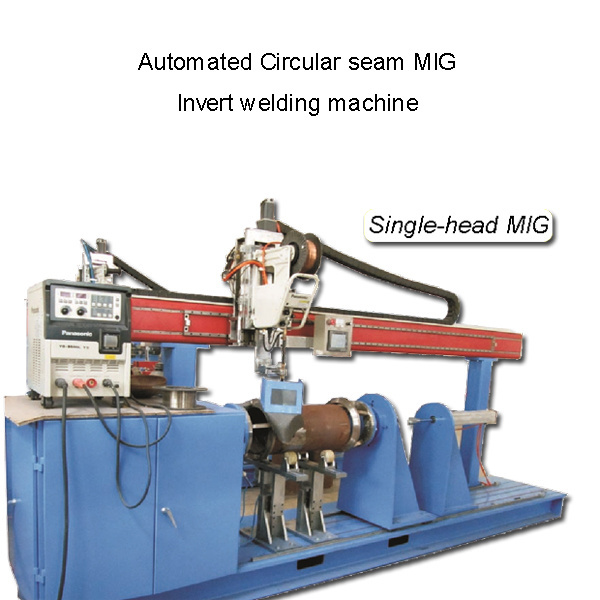

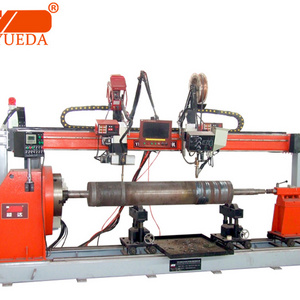

Automated circular seam MIG inverter welding mathine

TopSun Automated circular seam MIG inverter welding mathine are widely used by tank manufacturers as stand-alone machine or as part of assembly line operations.

Such circumferential lathe welder are widely used in production of solar water heater tank, enamel tank, LPG cylinder, large capacity welded insulated cylinder, storage tank, LNG gas station and so on.

Completely customized to meet customer’s requirements.

Our Automated circular seam MIG inverter welding mathine are with

Specifacations

|

Features |

1.

1 or 2 torches are usually built in.

2. Multiple torches up to 4-5 also could be integrated into this machine based on qnty. of welding seam and productivity. 3. Adjustable for various thickness 4. Precision longitudinal track for smooth travel 5. Change size automatically or manually |

| Applications |

Our precision Circumferential Lathe Welder are most commonly used in tank production.

|

|

Range of working piece |

Thickness of working piece: 0.3mm-10mm Dia. of working piece: 200mm-2500mm |

|

Custom Designed |

For any welders we fabricate and install, we can incorporate the controls system necessary. We program and wire electrical controls such as:

We use predominantly Allen-Bradley PLCs with touch-screen or panel view displays but we will incorporate any brand or type of controls our customers specify |

With our production and export experience with lathe welder, our team of engineers can custom design equipment.

We can tie-in our equipment with a current assembly line or machinery or supply an entire assembly line.

We also provide detailed technical drawings, user manual, work procedure and maintenance manual throughout the design, fabrication and installation processes