- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

kangheng

-

Width:

-

20-800mm

-

Length:

-

1800-5000mm

-

Grade:

-

steel, P20 steel

-

Model Number:

-

GB 3Cr2Mo/DIN 1.2330/AISI P20/BOHLER M202/Ss14 618, p20

-

Material:

-

Alloy Tool Steel

-

Special Use:

-

Mold Steel, plastic mould steel

-

Production route:

-

EF/EAF+LF+VD/ESR

-

Quality inspection:

-

UT, Chemical test, Microstructure, Physical properties etc.

-

UT test standard:

-

SEP1921-84 class3 C/c to D/d

-

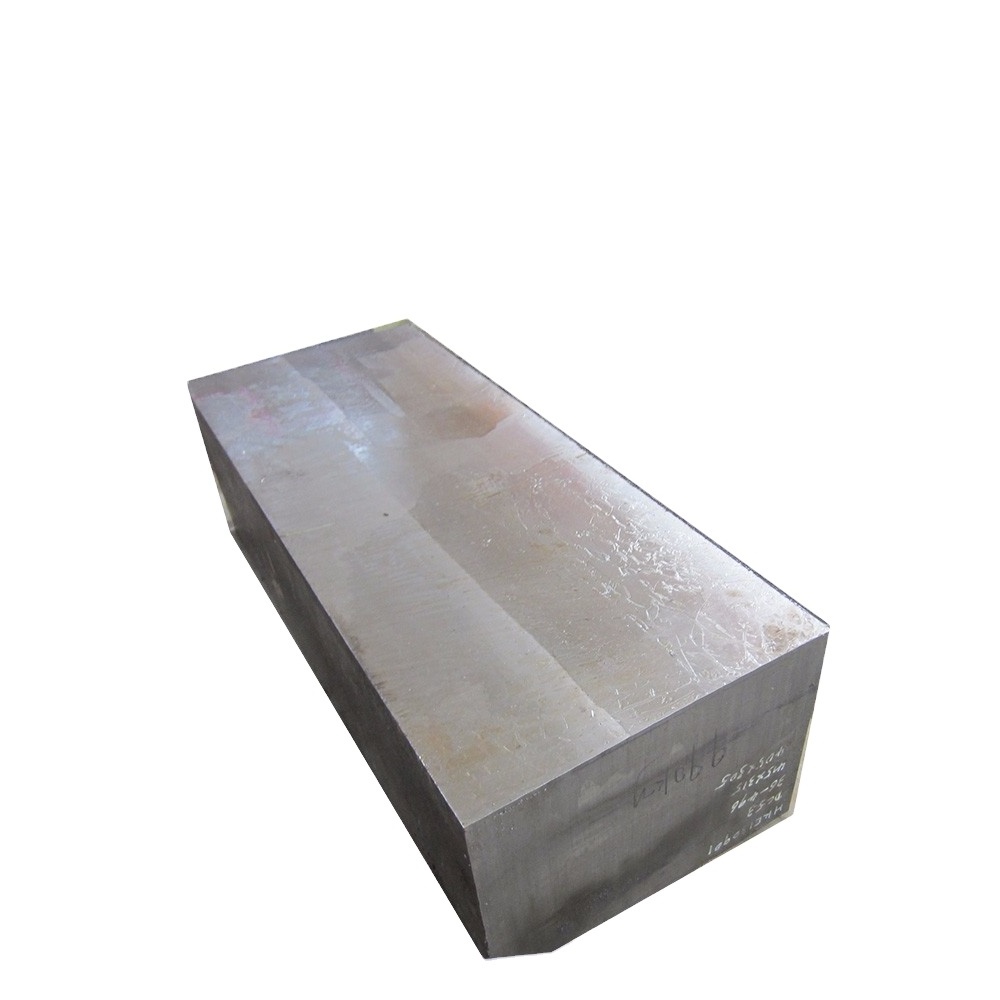

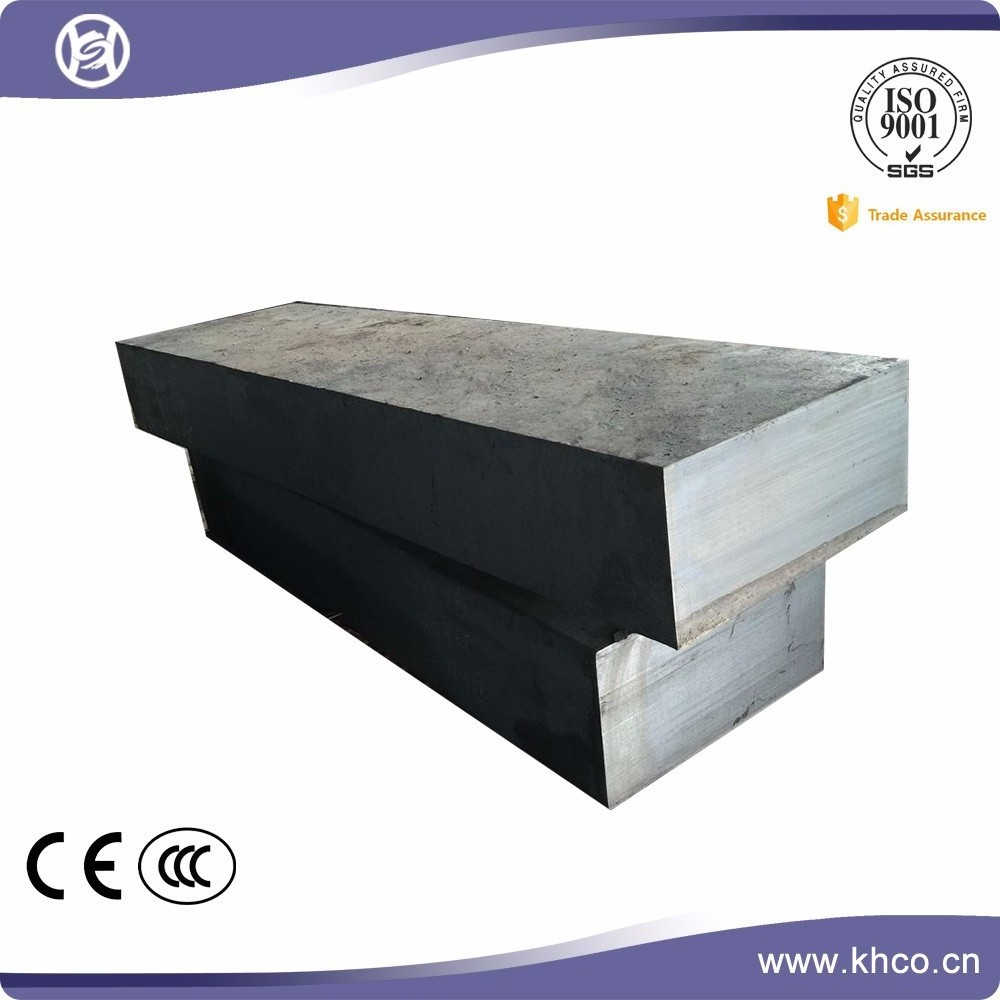

Surface treatment:

-

Black/Grinded/Machined/Turned

-

Certification:

-

ISO9001

Quick Details

-

Standard:

-

AiSi, ASTM, bs, DIN, GB, JIS

-

Tolerance:

-

±1%

-

Place of Origin:

-

Hubei, China

-

Brand Name:

-

kangheng

-

Width:

-

20-800mm

-

Length:

-

1800-5000mm

-

Grade:

-

steel, P20 steel

-

Model Number:

-

GB 3Cr2Mo/DIN 1.2330/AISI P20/BOHLER M202/Ss14 618, p20

-

Material:

-

Alloy Tool Steel

-

Special Use:

-

Mold Steel, plastic mould steel

-

Production route:

-

EF/EAF+LF+VD/ESR

-

Quality inspection:

-

UT, Chemical test, Microstructure, Physical properties etc.

-

UT test standard:

-

SEP1921-84 class3 C/c to D/d

-

Surface treatment:

-

Black/Grinded/Machined/Turned

-

Certification:

-

ISO9001

GB 3Cr2Mo/DIN 1.2330/AISI P20/BOHLER M202/Ss14 618 tool steel

Related Products

Product Description

| Steel Type | |||||

| GB | AISI | DIN | JIS | BOHLER | Ss14 |

| 3Cr2Mo | P20 | 1.2330 | / | M202 | 618 |

| Chemical Composition | ||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

| 0.28-0.40 | 0.20-0.80 | 0.60-1.00 | ≤0.030 | ≤0.030 | 1.40-2.00 | 0.30-0.55 | ≤0.25 | ≤0.30 |

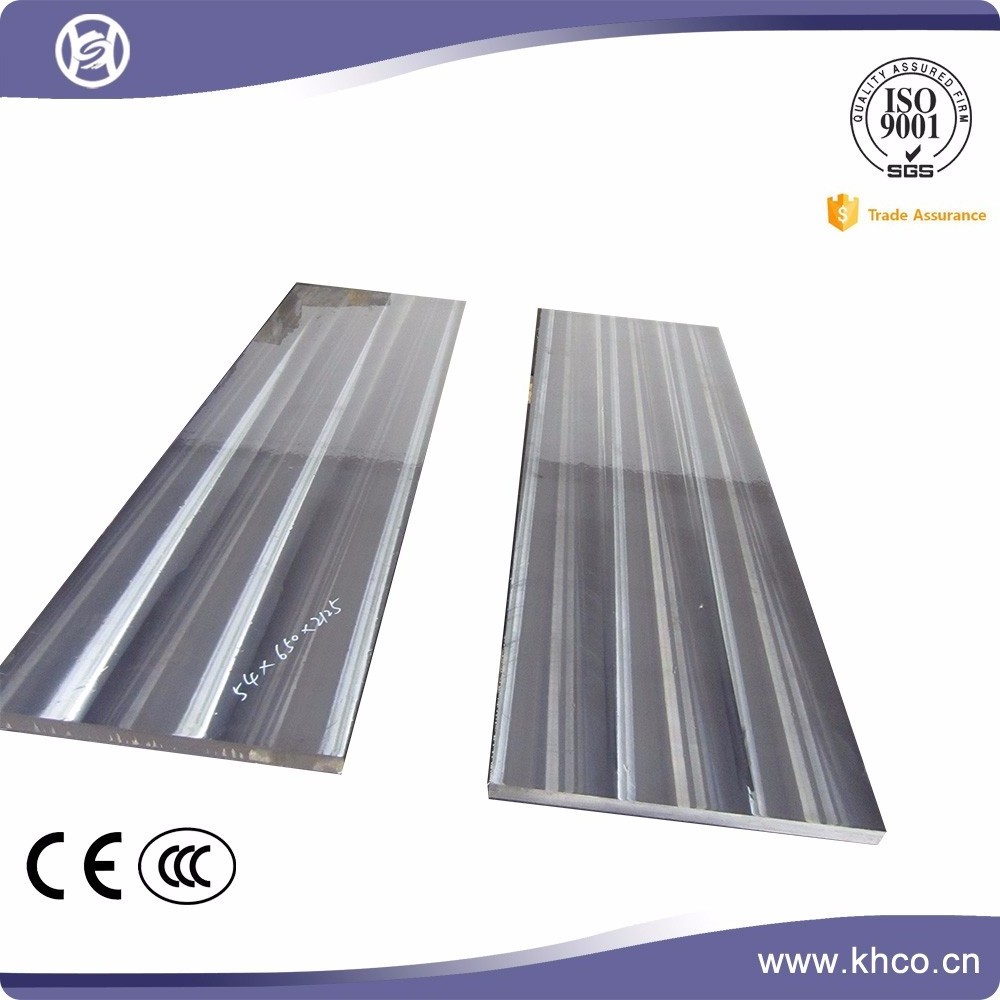

| Size of ASTM P20 (Can be Customised) | |||

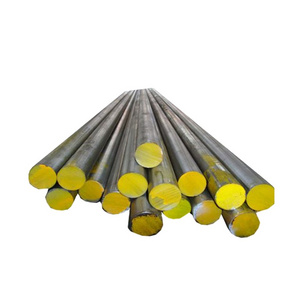

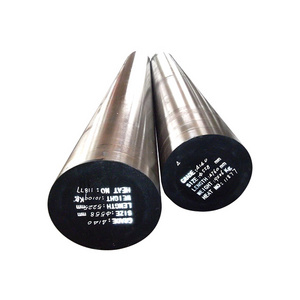

| Round Bar | Diameter(mm) | Hot Forged: φ50-500 | Length(mm):2500-5000 |

| Hot Rolled:≤50mm | |||

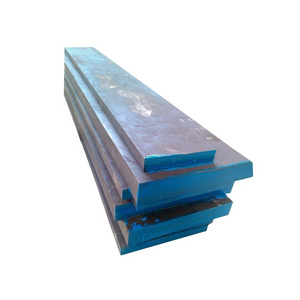

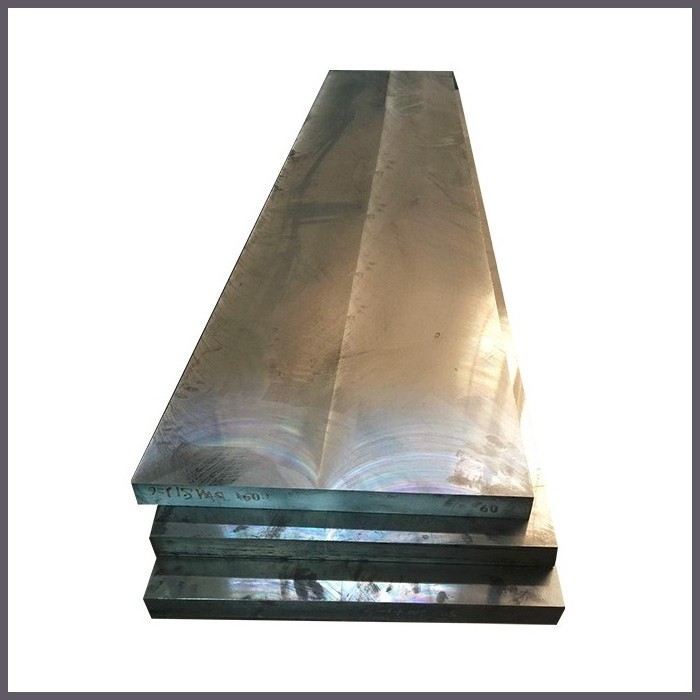

| Steel Plate | Thickness(mm) | Hot Forged:≥20mm | Width(mm):20-810 mm |

| Hot Rolled:≤20mm | |||

| Tolerance | ||||

| Round Bar | Black Surface | Peeled Surface | Turned Surface | |

| -0/+5mm | -0/+3mm | -0/+2mm | ||

| Steel Plate | Black Surface | Machined Surface | ||

|

Thickness:

-0/+5mm

|

Width:-0/+10mm | Thickness:-0/+3mm | Width:-0/+5mm | |

| Characteristics | |||

| 1.Good toughness properties; | |||

| 2.Easy to machine; | |||

| 3.Better polishability than 1.2312; | |||

| 4.Dimensional stability flame hardenable; | |||

| 5.Good photoengraving properties. | |||

| Applications | |||

| 1.Making plastic moulds; | |||

| 2.Frames for plastic pressure dies; | |||

| 3.Hydroforming tools. |

| Noted | |||

|

(1) Payment : 1.By confirmed, 100% valum irrevocable, letter of credit without recourse, Allowing partial shipment and transhipment, payable at sight presentation of shipping. |

|||

| 2.By T/T payment: 30% payment in deposited, 70% payment before shipment. | |||

| (2) Delivery Time : 45 days after received the buyer's L/C or T/T deposite payment. | |||

| (3) Delivery Port : Wuhan/Shanghai/Tianjin | |||

| (4) Process: Electric furnace melted, forged and annealed, round bar turned, flat bar machined. | |||

| (5) Hardness: Annealed HB235 MAX. | |||

| (6) UT Test: SEP 1921/84/2 C/c class. | |||

| (7) Allowance on quantity/weight: -/+ 10% per item. | |||

| (8) Package: Seaworthy Packing. |

Quality Control

Packing and Shipping

Hot Searches