- Product Details

- {{item.text}}

Quick Details

-

Raw material:

-

G550, full hard

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

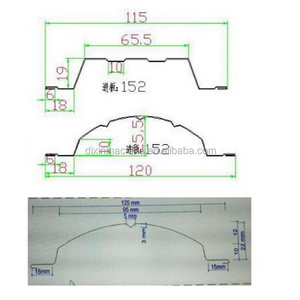

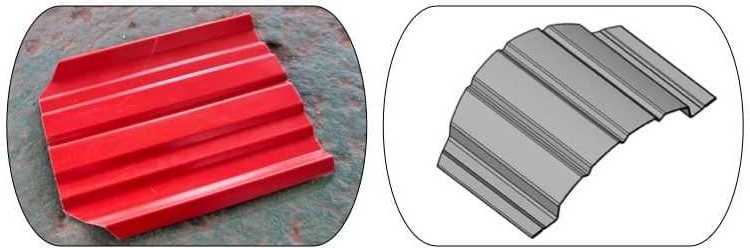

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

Quick Details

-

Weight (KG):

-

2536

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

TOPPO

-

Raw material:

-

G550, full hard

-

Operation Language:

-

English/Spanish/Chinese

-

Operate Style:

-

Auto/Manual

-

Motor Brand:

-

Japanese Simens

-

PLC Brand:

-

Delta/MITSUBISHI/SIEMENS

-

Cutting Blade:

-

Cr12Mov with quenched treatment

-

Profile:

-

as customer's requirement

-

Color of Machine:

-

blue, gray, or your required color

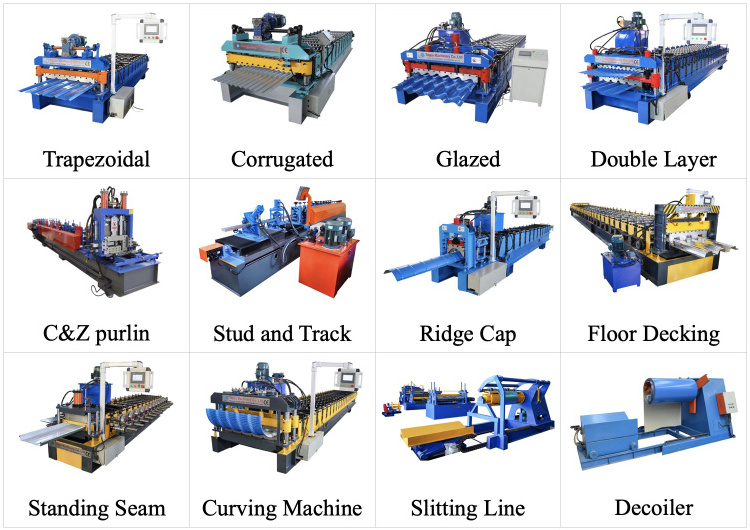

We have different types of roll forming machines.

Please click the following photos to see more photos for each type.

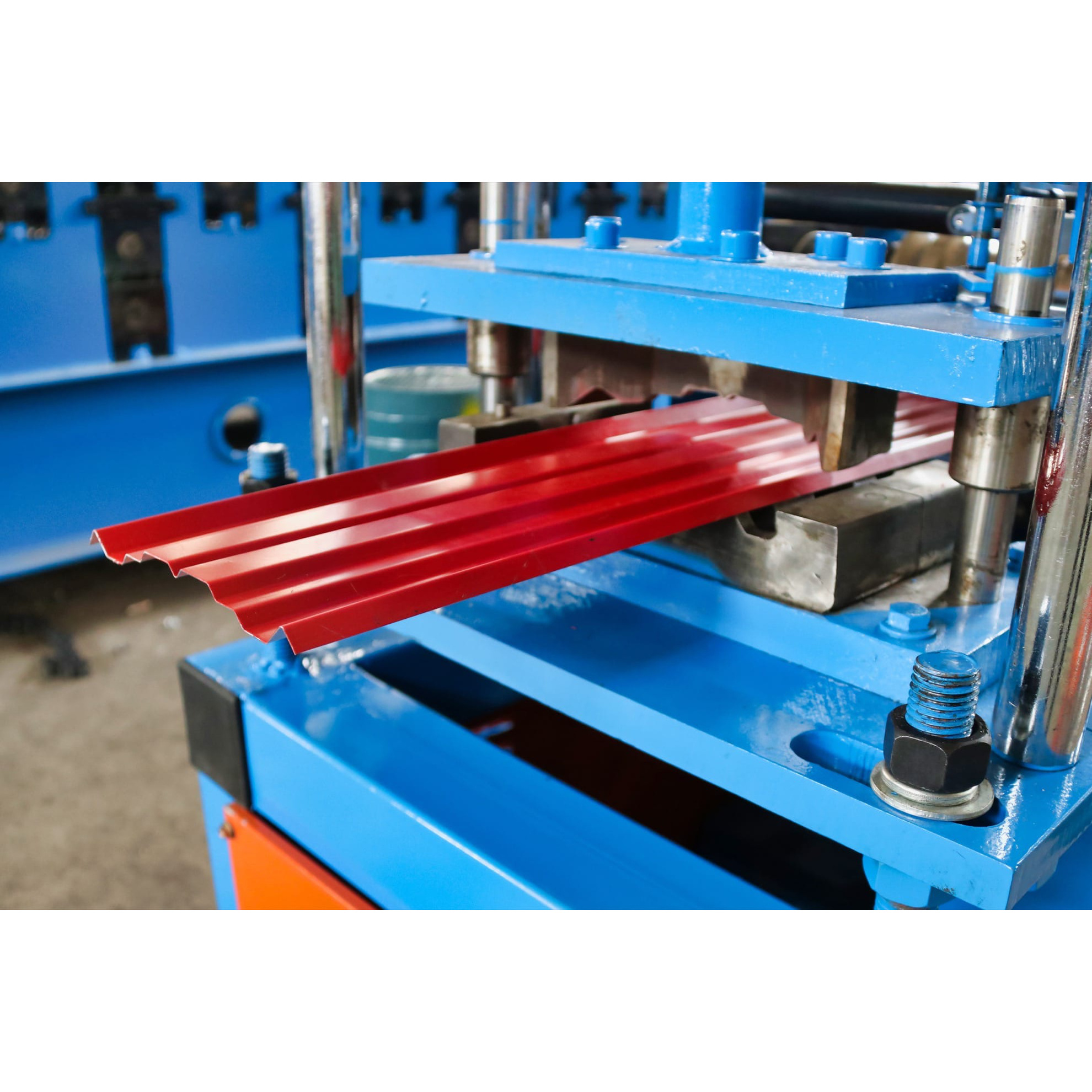

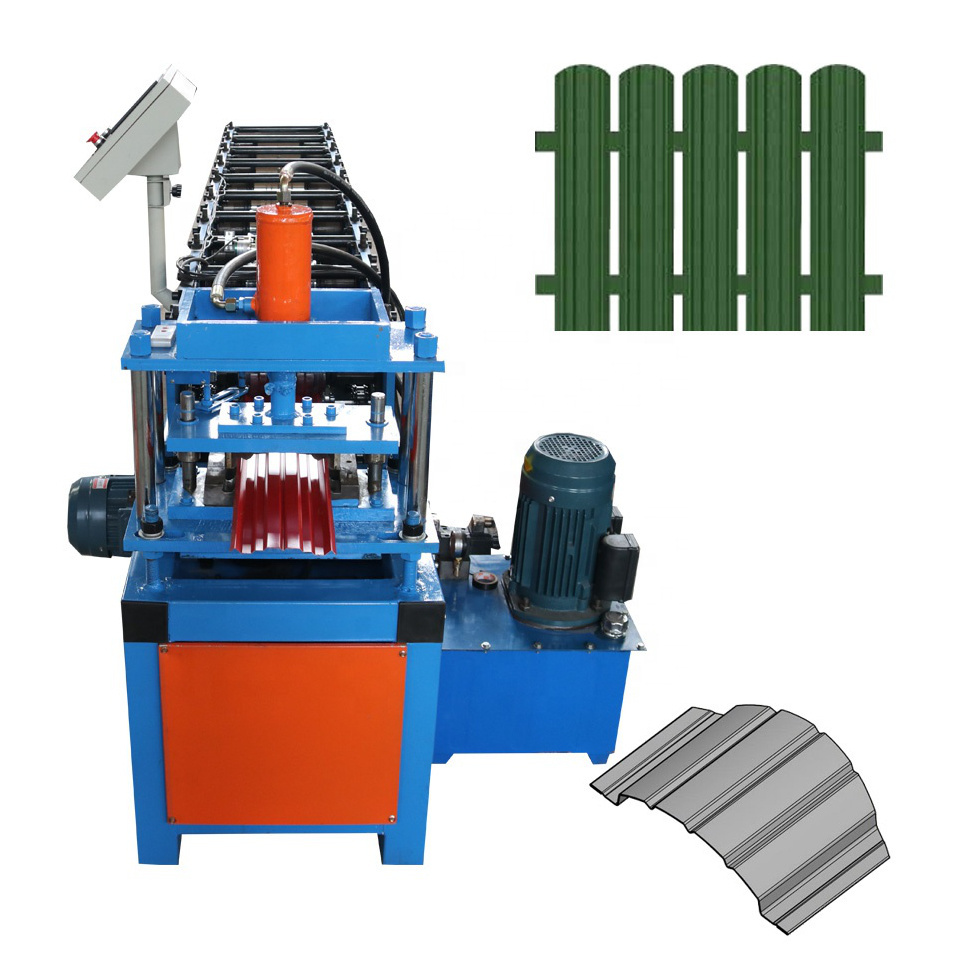

Metal Palisade Fence Roll Forming Machine, Fence Production Line

|

|

|

Uncoiler

Loading capacity: 5T Inner diameter: 470-530mm Steel coil width : 914, 1000, 1220, 1250 mm.According to your actual drawing. Working speed: 0-15m/min, adjustable |

|

|

Cutting system

Material of blade: Cr12MOV, much better than normal Cr12 material Hydraulic power: 3KW |

|

|

Main frame

Material: 350 H steel Feature: more table, no shaking |

|

|

Control cabinet

|

|

|

|

Feeding table

It is used to control the width and position of the steel sheet. The sheet is equipped into the machine in the correct position, to make sure the panel is neat and parallel |

The following items explain some advantages of our machines .

| High Grade | S tandard |

|

Motorized cutting is 3 times faster

than traditional hydraulic cutting.

you will

greatly improve your actual production speed. motorized cutting has the following advantages.

1. Easy maintenance. no extra hydraulic pipes to make it a mess

2. Low noise. the hydraulic station keeps working even it is not cutting.

3. Clean. No worry for oil leaking and making your factory dirty

|

|

|

|

|

|

This fast drive improves speed to 25m/minute

from the normal 10 m per minute (not including cutting).

Increase your production speed for the quick delivery to your customers.

the other benefit of high speed is to reduce labor costs. Now you can reduce

50% working time, and save 50% worker salary.

|

|

|

|

|

|

Our feeding table is a curved design.

So the panel will be folded marks when feeding into the machine. There is a handwheel to adjust the steel bar, so you can adjust for different widths easily.

|

|

1. Fit for ocean shipping.

2. The main body of the machine is tightly fixed to the container by steel wire.

3. Spare parts in the box.

5-star service

If you need any more information, be free to contact us. We will reply within 12 hours.

|

|

Jeffrey Yao |

|

|

Company |

BoTou Toppo Machinery Co., Ltd |

|

|

Address |

No 16, Development Zone, BoTou City, Hebei Province, China |

|

|

|

||

|

|

JeffreyYao |

|

|

Website |

||

|

YouTube |

||