- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Different size

-

Weight:

-

820 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Mineral course and fine particles

-

Color:

-

Customers' Request

-

Installation:

-

Engineer Guide

-

Feeding particle size:

-

< 5mm

-

Grading range:

-

0.4mm-0.04mm

-

Water consumption:

-

Depend on different models

-

Price:

-

Negotible

-

After sale service:

-

Maintenance

-

Function:

-

Screening\separation\sorting\sieving

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guote

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

Different size

-

Weight:

-

820 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Mineral course and fine particles

-

Color:

-

Customers' Request

-

Installation:

-

Engineer Guide

-

Feeding particle size:

-

< 5mm

-

Grading range:

-

0.4mm-0.04mm

-

Water consumption:

-

Depend on different models

-

Price:

-

Negotible

-

After sale service:

-

Maintenance

-

Function:

-

Screening\separation\sorting\sieving

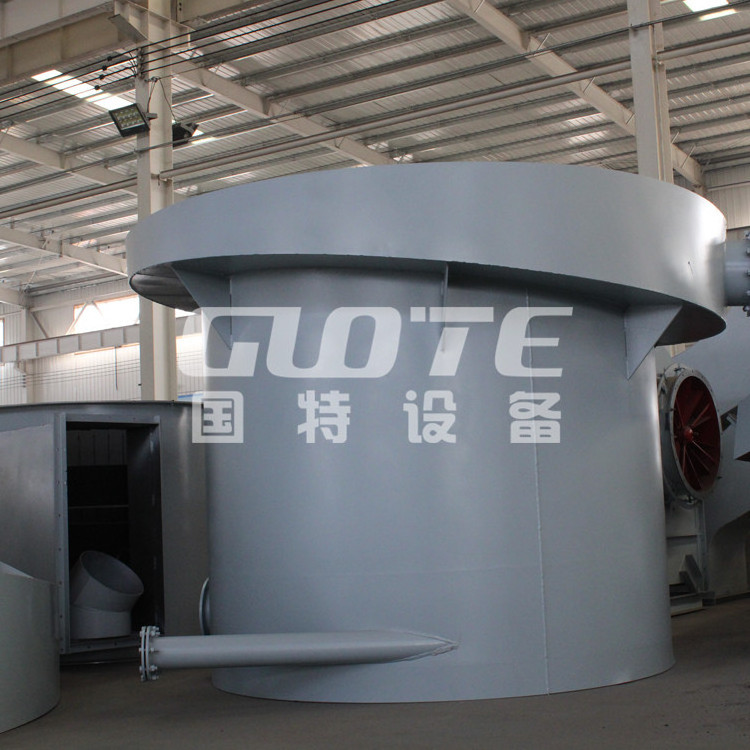

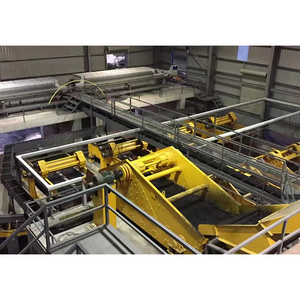

mineral separator equipment flat bottom classifier for quartz sand

Product Introduction :

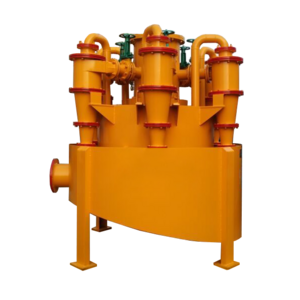

Hydraulic classifier is a kind of particle size classifier. It has the advantages of high efficiency, low energy consumption and no noise. It is an equipment system in the field of mineral classification

It is mainly used for fine grading of coarse and fine mineral particles

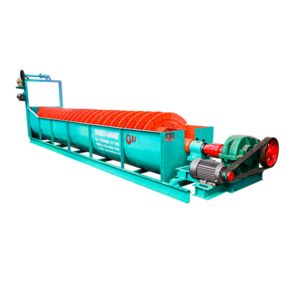

Application scope :

mainly used for strict grinding and selection of silica sand used in various industries ;grinding of coal powder and shale in the coal industry

Advantages :

1. The material is subjected to the action of upwelling water in the barrel to achieve the purpose of particle size grading and specific gravity separation, with high production efficiency and low energy consumption

2. Equipped with automatic control system, the adjustment of operation parameters is simple and convenient, easy to control

3. The water tank at the bottom of the barrel is equipped with special device. When the water is stopped, the rising water hole is closed automatically .The materials in the cylinder body will not block the hole and enter into the tank .

Sturcture and principle:

1. Mixing chamber: the grading is carried out under the condition of high slurry concentration because the coarse grains are sunk.

2. Grading room: regrading in rising water flow can be observed by glass Windows.

3.. Vortex chamber: feed water with high pressure.

4.. Lifting rod: tapered plug is provided at the lower end, and the size of stage clearance (grade ore grain size) is controlled by the screw rod.

5.. Sand sinking box (buffer box) : to prevent the destruction of the grading process of the jet stream in the process of sediment discharge, so as to ensure the normal continuous ore discharge.

Technical parameter:

| Model |

Feed size

(mm) |

Classification scope(mm) |

Capacity (t/h) |

Water consumption (m3/h) |

Weight(kg) |

| GSF1200 | < 5 | 0.4-0.04 | 3-7 | 10-15 | 820 |

| GSF1500 | < 5 | 0.4-0.04 | 7-10 | 15-20 | 1200 |

| GSF1800 | < 5 | 0.4-0.04 | 10-15 | 20-30 | 1770 |

| GSF2100 | < 5 | 0.4-0.04 | 15-20 | 30-40 | 2540 |

| GSF2400 | < 5 | 0.4-0.04 | 20-25 | 40-60 | 3260 |

| GSF3000 | < 5 | 0.4-0.04 | 25-40 | 50-80 | 4160 |