- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

800*800*1000MM

-

Voltage:

-

220-420V

-

Power:

-

17.5

-

Weight (KG):

-

7500

-

Product name:

-

Carbon Black Briquette Machine

-

Working Theory:

-

Continue Charcoal Machine

-

Applicable materials:

-

wood sawdust coconut husk

-

Applicable industry:

-

charcoal

-

Usage:

-

Charcoal Making Machine

-

Mould:

-

Customer Customization

-

Home installation:

-

support

-

Color:

-

Customer Customization

-

Keyword:

-

Coal Briquette Machine

-

Capacity:

-

1-3t/h

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kunteng

-

Effective Volume:

-

20m³

-

Dimension(L*W*H):

-

800*800*1000MM

-

Voltage:

-

220-420V

-

Power:

-

17.5

-

Weight (KG):

-

7500

-

Product name:

-

Carbon Black Briquette Machine

-

Working Theory:

-

Continue Charcoal Machine

-

Applicable materials:

-

wood sawdust coconut husk

-

Applicable industry:

-

charcoal

-

Usage:

-

Charcoal Making Machine

-

Mould:

-

Customer Customization

-

Home installation:

-

support

-

Color:

-

Customer Customization

-

Keyword:

-

Coal Briquette Machine

-

Capacity:

-

1-3t/h

Product Description

A lot of biomass waste is generated every day in the world, causing significant resource waste and environmental pollution.

KUNTENG machinery focus on developing various carbonization furnace and equipment to utilize waste biomass as renewable energy.

This is our latest carbonization furnaces for Anode Material production, industrial kilns for production anode active material, lithium-ion battery anode materials producer.

KUNTENG machinery focus on developing various carbonization furnace and equipment to utilize waste biomass as renewable energy.

This is our latest carbonization furnaces for Anode Material production, industrial kilns for production anode active material, lithium-ion battery anode materials producer.

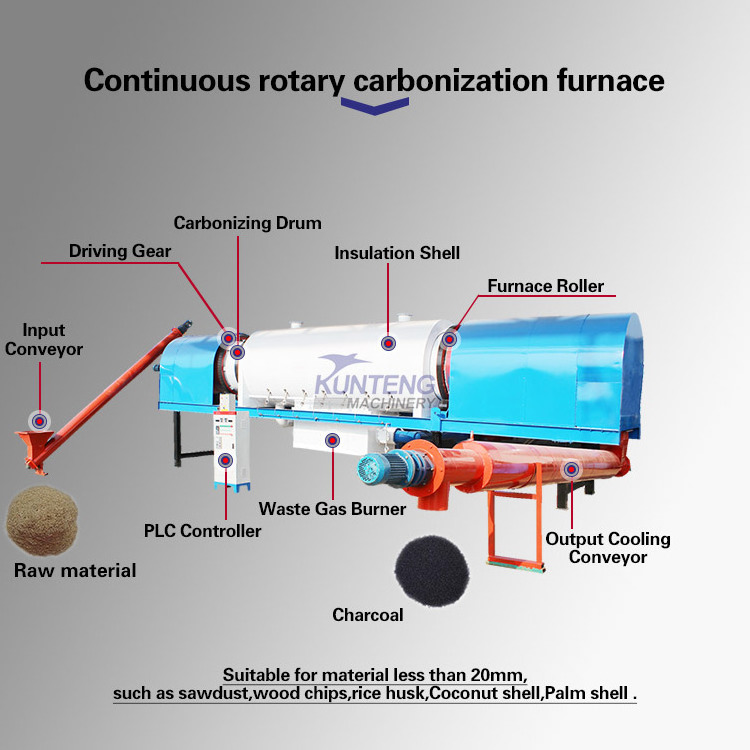

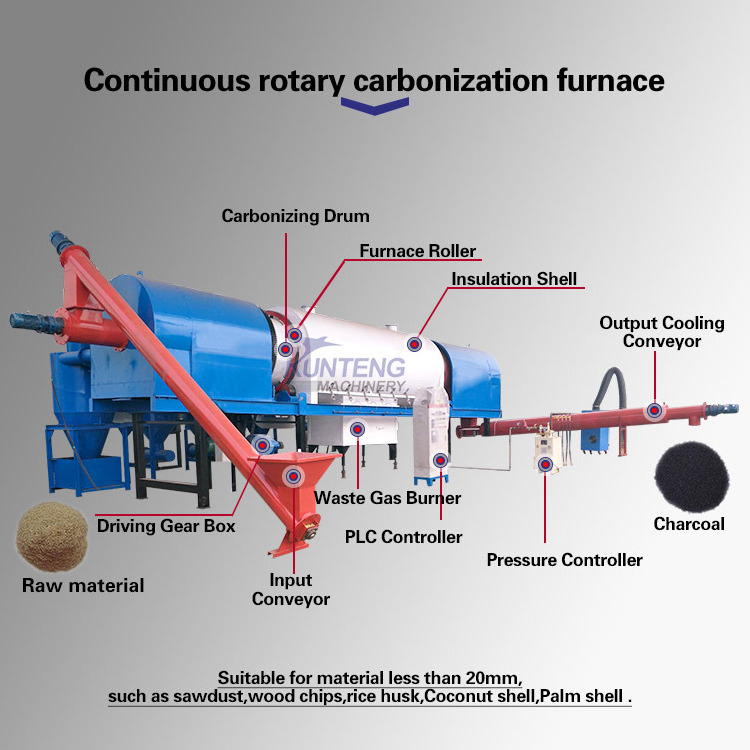

Machine Characteristics

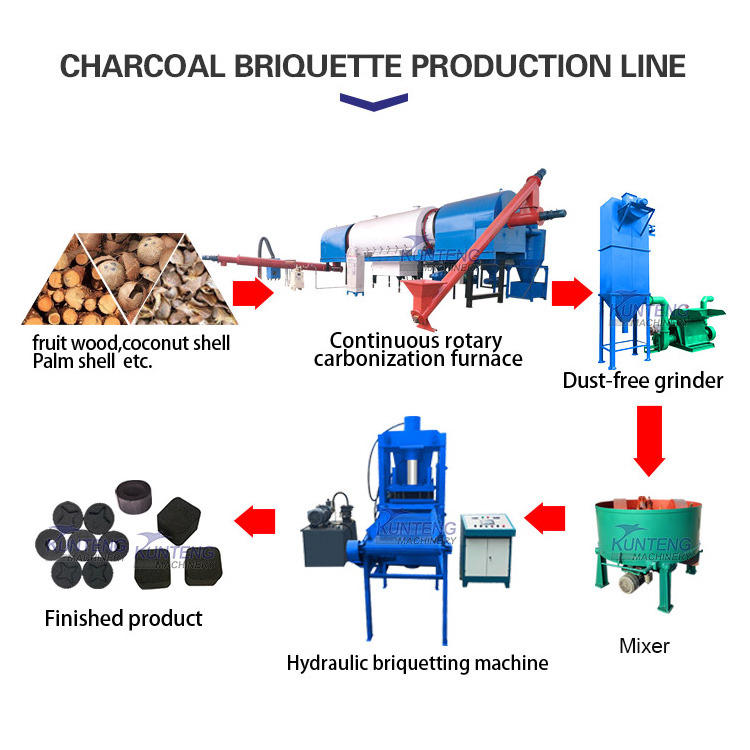

Wood chips, coconut shells, corn stalks, bamboo chips, etc. are crushed by a shredder. The crushed materials have a moisture content of ≤12% and can be directly carbonized. Otherwise, they need to be dried in a rotary dryer and then entered into a continuous rotary carbonization furnace for carbonization. - -- After carbonization, it becomes charcoal powder, which has a wide range of uses, such as being used as fuel and as anode material for lithium-ion batteries.

Process Flow

Specification

|

type

|

size

|

production

|

power

|

gross weight

|

|

KT800-10000

|

φ800*10000mm

|

1000kg/h

|

17.5kw

|

7500kg

|

|

KT1200-10000

|

φ1200*10000mm

|

2000kg/h

|

20kw

|

9200kg

|

|

KT1500-10000

|

φ1500*10000mm

|

3000kg/h

|

29kw

|

13600kg

|

We have different models of equipment that you can purchase according to your needs. If the above models are not suitable, please contact us.

CUSTOMER VISIT

Hot Searches