- Product Details

- {{item.text}}

Quick Details

-

Power:

-

125 W

-

Dimension(L*W*H):

-

35000*20000*4000mm(L*W*H)

-

Weight:

-

2100 KG

-

Warranty:

-

1 year warrenty

-

Production Capacity:

-

100%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Non woven fabrics making machine

-

Fiber type:

-

natural fiber or synthetic fiber etc.

-

Working width:

-

≤3600mm

-

Product weight:

-

100~9000gram/m2

-

Product thickness:

-

3~200mm

-

Heating method:

-

hot oil circulation, electricity heating, direct burning

-

Oven working width:

-

4.8m-9.0m

Quick Details

-

Voltage:

-

380V 50HZ

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONGDA

-

Power:

-

125 W

-

Dimension(L*W*H):

-

35000*20000*4000mm(L*W*H)

-

Weight:

-

2100 KG

-

Warranty:

-

1 year warrenty

-

Production Capacity:

-

100%

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Non woven fabrics making machine

-

Fiber type:

-

natural fiber or synthetic fiber etc.

-

Working width:

-

≤3600mm

-

Product weight:

-

100~9000gram/m2

-

Product thickness:

-

3~200mm

-

Heating method:

-

hot oil circulation, electricity heating, direct burning

-

Oven working width:

-

4.8m-9.0m

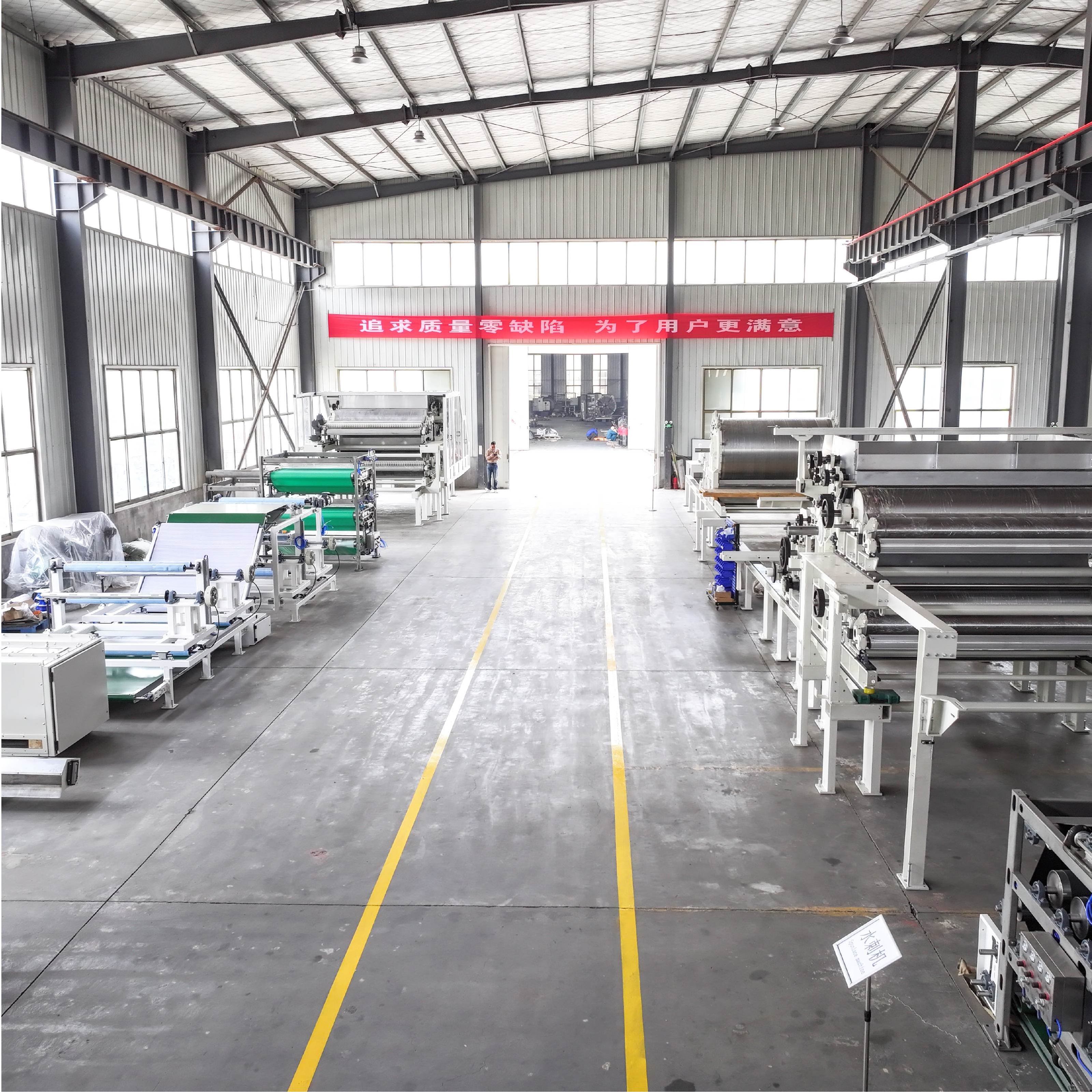

Product display and advantages

Main Feature

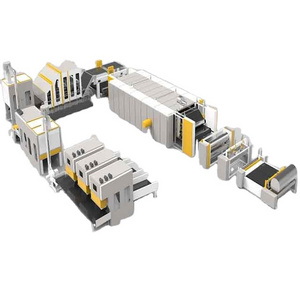

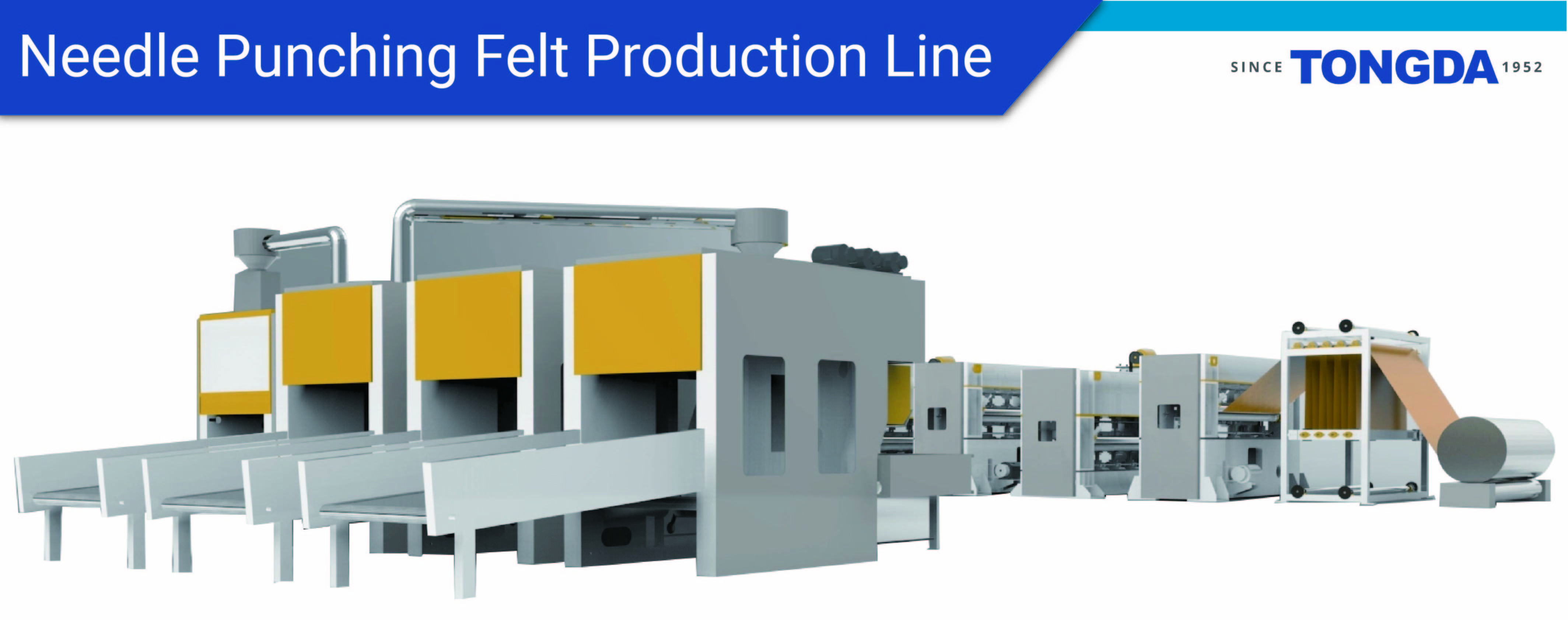

Needle punching line (tongda-needle-punching-line)are mainly used in technical textiles. The range of applications is broad - a wide variety of natural, chemical, high-performance or mineral fibers can be processed.Our line concepts are precisely tailored to the respective application of the finished nonwoven. Our machine range by a larger selection of high-performance crosslappers perfectly suited to the application and also by state-of-the-art needling machines.

Function and Characteristics

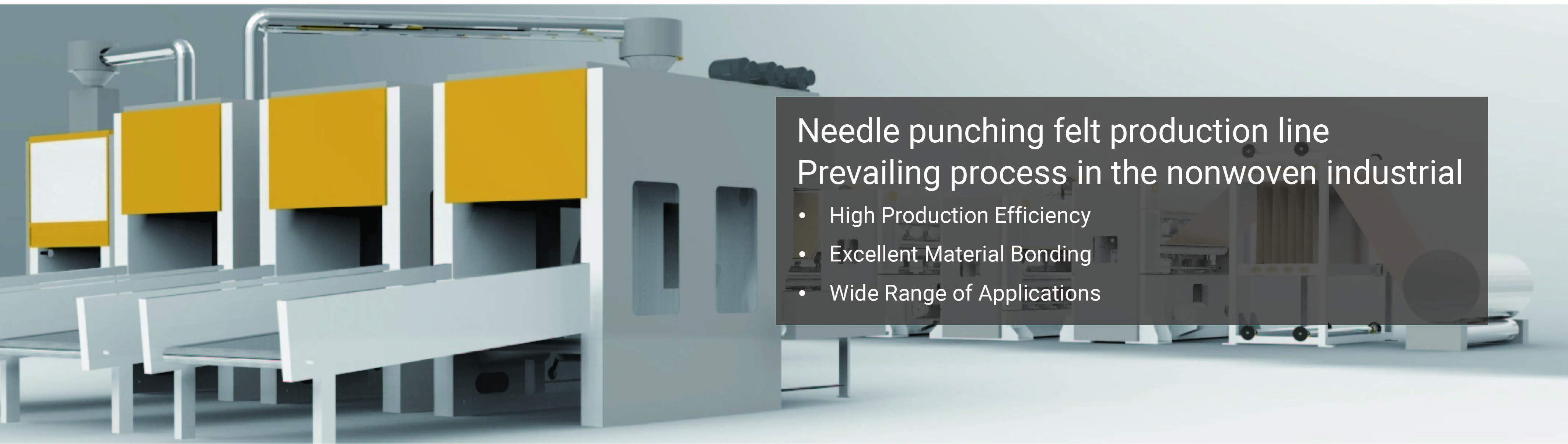

Used to make all types of heat-resistant upscale filter used in industrial production of materials prone to any amounts of dust and exhaust gas in the atmosphere.

The machine unit integrated both needle punching and thermal boonding processing to make the nonwovens media

for automobile engine air intake, pre-filtration media for passage aautomobile, filter fabric for engine oil, air conditioner filter fabric and so on.

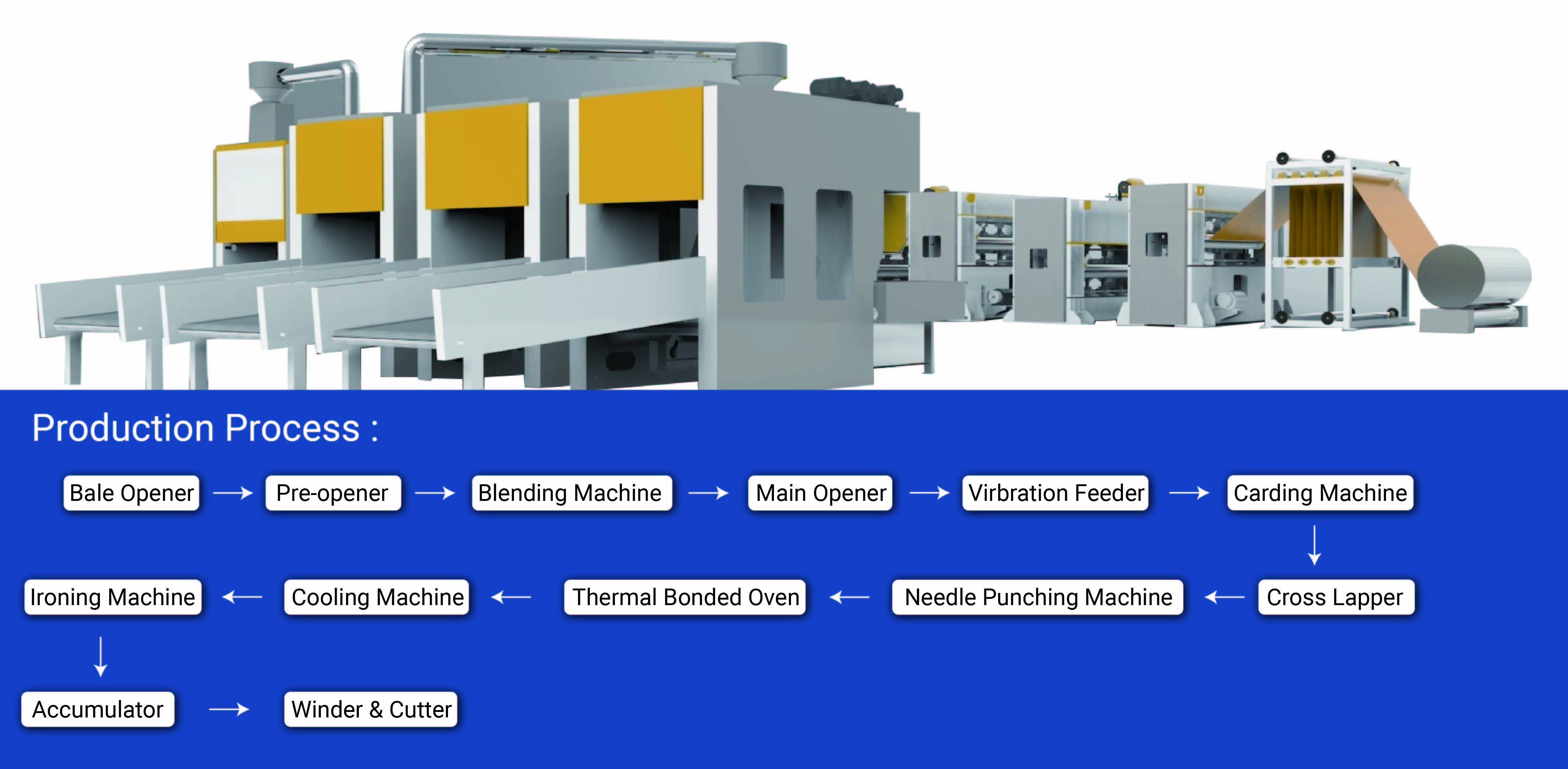

Product Parameters

|

Main specification

|

|

|

|

Product net width

|

<3200mm

|

|

|

Production specification

|

≤400g/m2

|

|

Main products

Function and Characteristics

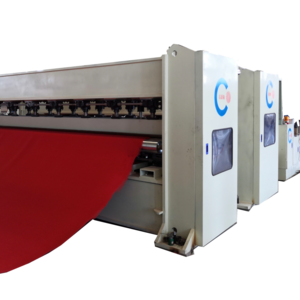

To vertical, cross cut and neatly roll finished punching fabrics to specified roll length.

For soft nonwovens, automatic winding, doffing, roll changing is available as an option if customer choose such design.

Linear guide is an option for vertical cutting; the vertical cutting frame is installed on the linear guide, which is very convenient for movement and adjustment. Normal design is without linear guide.

Linear guide along with synchronous belt is an option for cross-cutting, with smooth running, low noise and no oil dirty. Normal design is combination of the chain and wheel.

For geotextile and asphalt felt substrate, which have particular requirement for the roll diameter, an added pressure roller is an option to make the winding more compact.

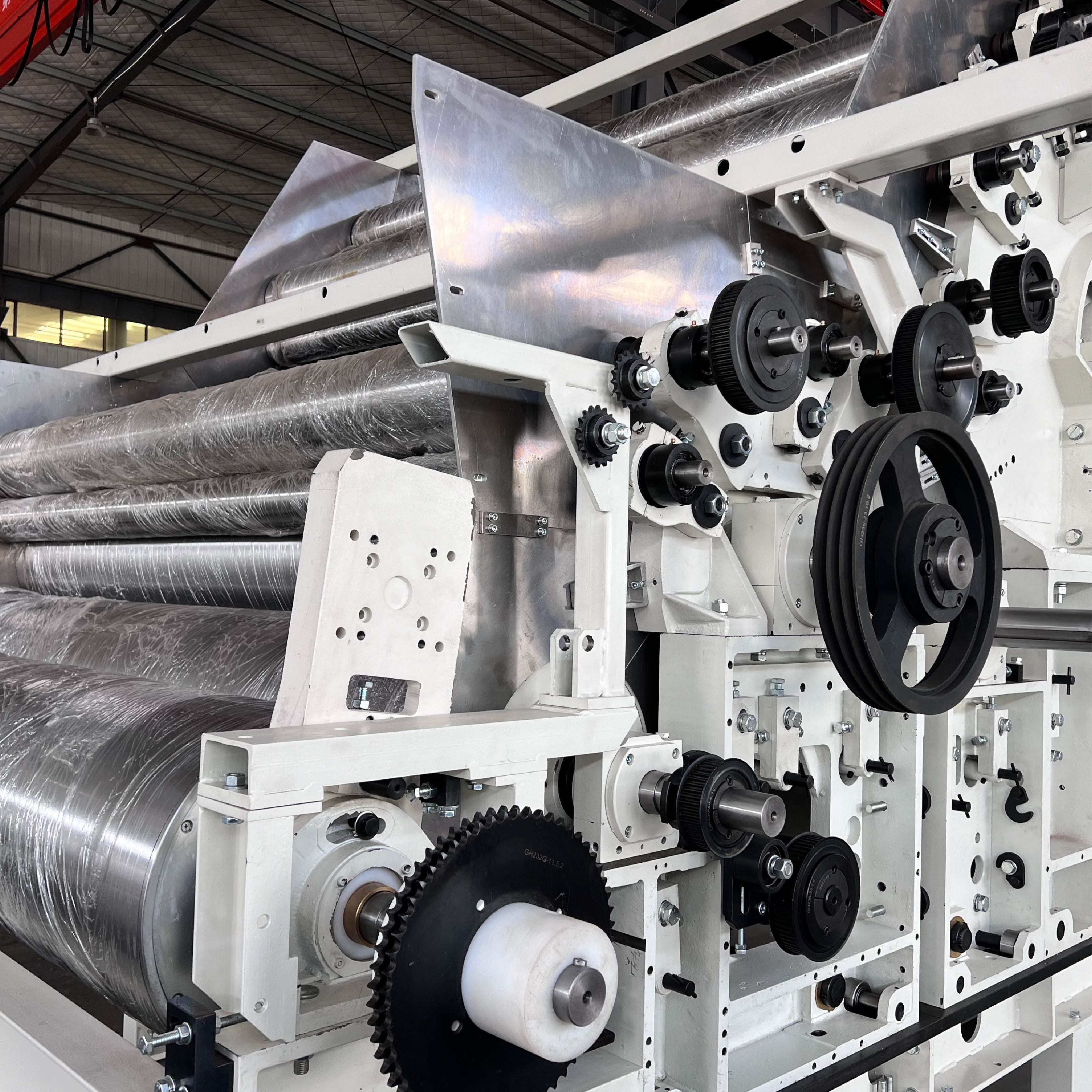

Function and Characteristics

The tandem needle loom belongs to nonwoven fabric machines. It is used for reinforcing and surface finishing of the nonwoven fabrics. Crank case complete with a vertical balance system.Central oil lubrication circulation and cooling system complete with pressure and temperatrure alarm systems. Magnesium alloy/ PU combined needle board locked firmly by lock-bolt or air tube; multi random delivery rollers with carved or patterned surface. Auto top dead center controlled stop.

Needle beam’ movement is controlled by the electronic worm wheel, depth meter display.

Function and Characteristics

This machine is used for drafting the folded batt from the crosslapper through multiple sets of variable speed rollers, each group with its own independent drive unit.This allows for a more uniform MD, CD orientation and better surface quality. Meanwhile, to adjust unit weight of web and increase the line speed.

1.High precision draft rollers with surface wired card clothing arnd adjustable roller spacing.2.The draft ratio can be gradually adjusted through frequency colnversion technique and multiple sets of motor drives to guarantee the web uniformity.3.Upper and bottom drafter rollers can be raised/lowered integrally to allow different density web through it and easy to be cleaned.

Title goes here.

To pre-open all kinds of fiber from bales then weighing pre-determined percentages as required for a total blend. Weighing is by electronic scale and transfer of material iis by cross conveyer to the opener.Weigh by required proportion weighing accuracy +3%

Control of the spiked lattice and fiber leveling roller by seperate inverterLenathened feeding apron and load-bearing aapron are available

Why Choose Us

Regarding the package & delivery

Hot Searches