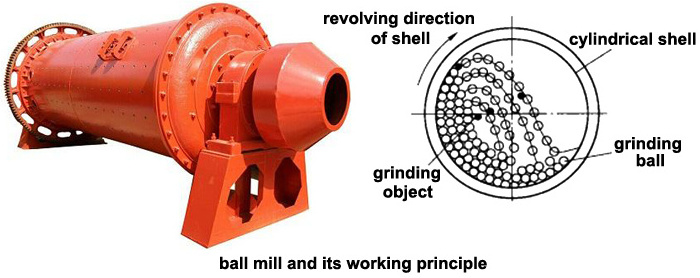

The motor on the ceramic ball mill drives the cylinder to rotate through the deceleration device, and then the crushed ore and the grinding balls in the cylinder are brought to a certain height by the lining plate due to the friction and centrifugal force when the cylinder rotates, and then fall and fall due to gravity. Falling, the ore is gradually crushed under the action of impact and grinding. The crushed ore is discharged out of the barrel through the discharge part. After the discharged minerals are classified into qualified products in the spiral classifier, the coarse sand passes through the combined feeder and returns to the ball mill to continue grinding. The feeder feeds continuously and evenly, the ore enters the ceramic ball mill continuously and uniformly through the combined feeder, and the

ground materials are continuously discharged from the ceramic ball mill. Ceramic ball mill is a grinding equipment that can work continuously 24 hours a day.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XKJ

-

Application:

-

Engineering

Quick Details

-

Weight (KG):

-

3200

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XKJ

-

Application:

-

Engineering

Principle Structure

Principle

Application

It is widely used in cement, silicate products,new building materials, refractory materials, chemical fertilizer, black and non-ferrous metal dressing, and glass and ceramics,with dry or wet abrasive ore and other abrasive materials.

Custom Visit

Advantages

1. The ceramic ball mill can use different liner types according to production needs to meet different needs.

2. The fineness of the grinding operation is controlled by the grinding time.

3. The motor starts from decompression and reduces the starting current. Its structure is divided into integral type and

independent type.

4. The ceramic ball mill has less investment, is energy-saving and electricity-saving than similar products, has a novel

structure, simple operation, safe use, and stable and reliable performance.

5. The user can choose the appropriate model and liner according to the specific gravity and hardness of the material, as well as the output and other factors.

2. The fineness of the grinding operation is controlled by the grinding time.

3. The motor starts from decompression and reduces the starting current. Its structure is divided into integral type and

independent type.

4. The ceramic ball mill has less investment, is energy-saving and electricity-saving than similar products, has a novel

structure, simple operation, safe use, and stable and reliable performance.

5. The user can choose the appropriate model and liner according to the specific gravity and hardness of the material, as well as the output and other factors.

Parameters

|

Model

|

Loading Weight(t)

|

Cylinder RPM(r/min)

|

Reference Power(kw)

|

Liner Material

|

|

600×700

|

0.05

|

50

|

2.2

|

Ceramics,silica,rubber,metal(auxiliary power based on the use of lining material and abrasive material will vary)

|

|

800×600

|

0.075

|

42

|

3

|

|

|

1300×1500

|

0.5

|

33

|

7.5

|

|

|

1500×1800

|

1.2

|

28.5

|

11

|

|

|

1800×2000

|

1.5

|

24

|

15

|

|

|

2600×2800

|

5

|

016.5

|

37

|

|

Why Choose Us

Production strength

XKJ GROUP now occupied 40000 m', with building area 10000m',manufacture equipment more than 60 sets, has already build up advantage technology workflow production line . With experiencelabor 365, there are 38 engineers support the technical for the machinery manufacture. Establish well selling network has alreadyown international sales department, area sales agent and typical project demonstration sales. Also have branch company in China Tibet.

working site

FAQ

1. Which are the common types of Grinding Mills?

The Common Types of Grinding Mills are. 1. Ball Mill. 2. Tube Mill. 3. Rod Mill. 4. Pebble Mill. 5. Batch Mill. 6. Grate

Discharge Mill. 7. turn Overflow Mill.

2. Which are the key component of a Grinding Mill?

The key components of a Grinding mill are Shell Plate, Feed-End Plate, Discharge-End Plate, Manhole, Gear Box, Mill Liners,

Grinding Media etc.

3. Which are the main types of Mill Liner?

The main types of Mill Liners are Solid Steel Liners, Manganese Liner & Rubber Liner.

The Common Types of Grinding Mills are. 1. Ball Mill. 2. Tube Mill. 3. Rod Mill. 4. Pebble Mill. 5. Batch Mill. 6. Grate

Discharge Mill. 7. turn Overflow Mill.

2. Which are the key component of a Grinding Mill?

The key components of a Grinding mill are Shell Plate, Feed-End Plate, Discharge-End Plate, Manhole, Gear Box, Mill Liners,

Grinding Media etc.

3. Which are the main types of Mill Liner?

The main types of Mill Liners are Solid Steel Liners, Manganese Liner & Rubber Liner.

Hot Searches