- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Stud And Track Steel Truss Roll Forming Machine

-

Raw material:

-

Galvanized Steel

-

Roller material:

-

Gcr15 steel with quenching

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45#steel

-

Cutting type:

-

Hydralic Cutting

-

Control system:

-

PLC with touch screen

-

Certification:

-

CE ISO SGS

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

10-15m/min

-

Place of Origin:

-

Jiangsu, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Stud And Track Steel Truss Roll Forming Machine

-

Raw material:

-

Galvanized Steel

-

Roller material:

-

Gcr15 steel with quenching

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Shaft material:

-

45#steel

-

Cutting type:

-

Hydralic Cutting

-

Control system:

-

PLC with touch screen

-

Certification:

-

CE ISO SGS

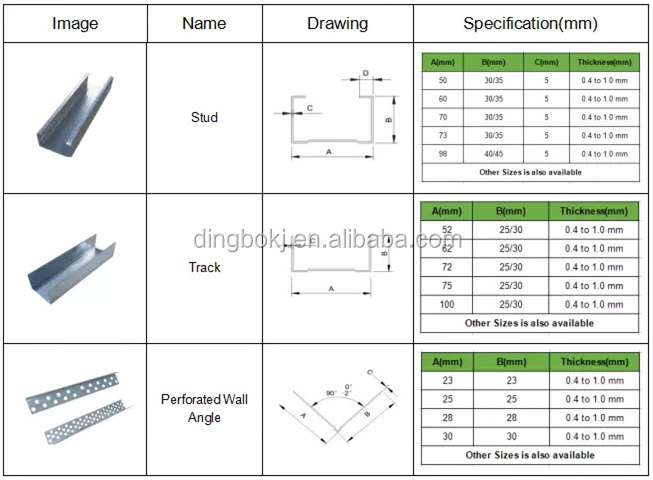

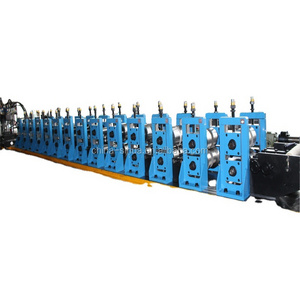

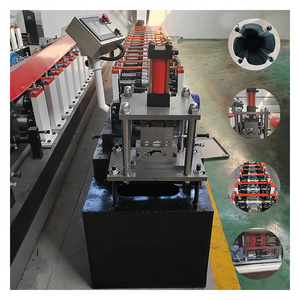

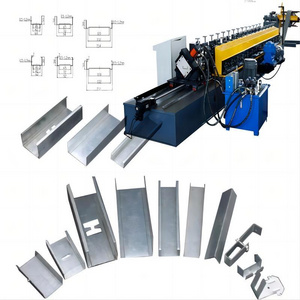

Stud And Truss Profile Roll Forming Machine

Main features

Metal drywall roll forming machine with UD CD UW CW Profiles offer builders a competitive alternative to traditional wood trusses. Flexibility and design advantages. Our machine could update with the fashio for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling.

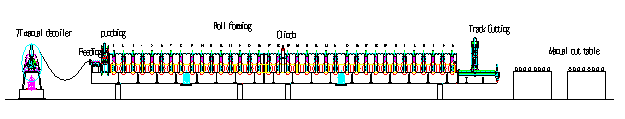

Working flow

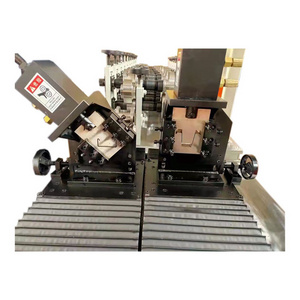

Uncoiling—Guiding—Roll forming—Punching—Servo track cutting —Products collecting

Technical parameters

|

Manual Un-coiler |

◊ Max Capacity: 5000kgs ◊ Inner diameter of coil: 400-600mm ◊ Manual type |

|

Leveling Device |

◊ Ensure the material level and straight

|

|

Main Forming System |

◊ Materialt width:

As per sketch

◊ Forming speed: 30-40m/min

◊ Motor Power: 2.2kw

|

|

Hydraulic Cutting Device |

◊ Servo t racking: 1.1kw

◊ Cutting power: 3kw

|

|

Electrical System |

◊ Control system: PLC control panel.

|

|

Run-out Table |

◊ Frame: 8# steel groove welded

|

Profile drawing