- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±2mm

-

Voltage:

-

According to customer requirements

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

King Machine

-

Dimension(L*W*H):

-

According to customer requirements

-

Weight:

-

5000 KG

-

Keywords:

-

Bottled Water Filling Machine For Small Business

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

Drinking Water

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304/316

-

Capacity:

-

2000-30000bph

-

Filling volume:

-

200ml-2000ml

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Normal Pressure Filling

-

Product name:

-

Bottled Water Filling Machine For Small Business

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Metal, Glass

-

Filling Material:

-

Other, Water

-

Filling Accuracy:

-

±2mm

-

Voltage:

-

According to customer requirements

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

King Machine

-

Dimension(L*W*H):

-

According to customer requirements

-

Weight:

-

5000 KG

-

Keywords:

-

Bottled Water Filling Machine For Small Business

-

Function:

-

Bottle Washing Filling Capping

-

Filling material:

-

Drinking Water

-

Bottle type:

-

PET Plastic Bottle

-

Material:

-

Stainless Steel 304/316

-

Capacity:

-

2000-30000bph

-

Filling volume:

-

200ml-2000ml

-

Control:

-

PLC+ Touch Screen

-

Processing Types:

-

Normal Pressure Filling

-

Product name:

-

Bottled Water Filling Machine For Small Business

Zhangjiagang King Machine Co.,Ltd

Zhangjiagang King Machine Co., Ltd. is a professional manufacturer of beverage machinery in China.Our main products have: Water filling production line, juice filling production line, carbonated drinks production line, and also aerosol filling machine, 5 Gallon bottle filling production line, and all other auxiliary equipment.

Our engineers are located all over the world and can provide safe and fast service to your beverage production solutions in your country.

Products Description

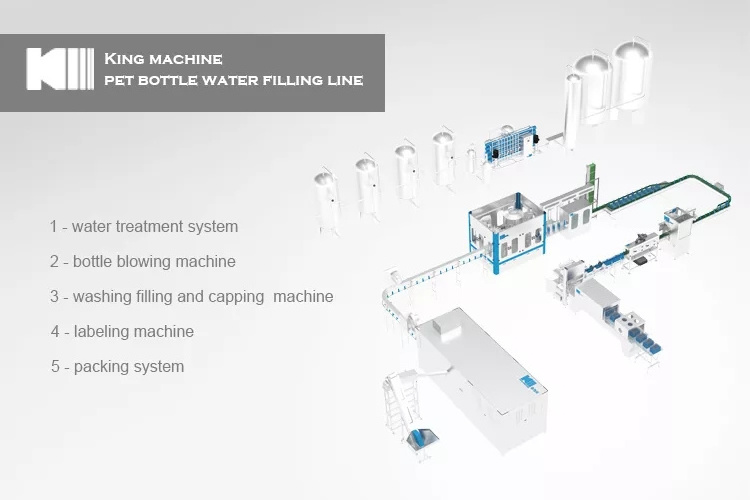

Water Lines.

A complete water line solution from King Machine leverages our knowledge of the entire water bottling process, from minimising waste of resources, to ensuring that your bottle is durable and attractive to consumers.

With everything centred around one supplier,

you get wide-ranging expertise, line equipment and ongoing services. This ensures high quality and efficiency from packaging to equipment, fast ramp-up and beyond.With over 20 years of experience designing and implementing custom complete PET water line solutions, we can help you achieve your production goals. Over the years, we've significantly reduced the weight of water bottles while maintaining their durability and expanding design opportunities.

Boosting speed and hygiene , King Machine Water lines provide:

1 - Water packing solutions to reduce your total cost of ownership

2 - Higher speeds with gentler handling

3 - Hygienic production for top quality water

4 - Reduced consumption with more efficient resources use

2 - Higher speeds with gentler handling

3 - Hygienic production for top quality water

4 - Reduced consumption with more efficient resources use

Product Details

Water Treatment System

1 Raw water tank + Raw water pump

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

2 Silica sand filter + Active carbon filter + Sodium ion exchanger + Precision filter + Security filter

3 Reverse Osmosis (one level)

4 UV sterilizer

5 Finished water tank + Pure water pump1/Stainless steel high pressure film shell

2/All kinds of capacity indicator, pressure indicator, electricity magnetic valve, balance device and pipe valve system

3/Online type pressure auto self-protection device

4/Online type electricity indicator (with stable compensation)

5/System safe protecting and alarm system

6/System frame

Bottle Blow Molding Machine

1 / King Machine Blower : Industry-leading blower performance with patented control and self-regulation systems for repeatable and

consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

consistently high bottle quality

2 / Production flexibility: Up to 200 different equipment size configurations from one platform

3 / Top quality: Electrical stretching for bottle integrity, full material distribution control and performance

4 / Fast output: Boosted uptime and speed (up to 2,400 bottles/mould/hour)

5 / Efficient consumption: Up to 45 % less electricity and 35 % less compressed air

Water Filling Machine [ Washing Filling Capping 3 in 1 type ]

1 / Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

5 / Automatic dummy bottles: Safer, easier cleaning procedures

6 / Automatic bottle changeover improves uptime

2 / Optimum uptime: 30 % reduction in changeover and maintenance downtime

3 / Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4 / Hygiene improvement through volume control and contactless filling

5 / Automatic dummy bottles: Safer, easier cleaning procedures

6 / Automatic bottle changeover improves uptime

|

Equipment Type

|

Automatic

|

|

Bottle Type |

PET round or square bottle

Volume 200 - 2000ml Bottle diameter 50-115mm Bottle height 160-320mm |

|

Output

|

up to 72,000 bph

|

|

Your product

|

mineral water/pure water/non-gas wine drink and so on.

|

|

Certificates

|

CE / SGS / ISO 9001

|

Labeling Machine

Boasting four carousel sizes, up to three labelling stations and 24 configurations, can generate outputs of up to 72,000 containers per hour, when standalone, at an efficiency rate of 98%.

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

Benefits

1 / Greater performance and ergonomics

2 / Boasted production uptime

3 / Sustainable and quality production

Packing Machine

Once your beverage product has been filled and the bottle has been labelled, the primary package is gently transferred using conveyors to its secondary packaging process. The final result is the package the customer sees at the point of sale, so it needs to grab their attention. These packs ensure protection from elements such as weather, pressure and temperature changes. Whether you choose shrink-printed film, nested packs or wraparound cartons, King Machine packers gently feed bottles to ensure durable and cost-effective packs.

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Benfits.

1 / Pack consistency and quality

2 / Gentle and precise infeed configuration

3 / Flexible handling of multiple SKUs

4 / Automatic pack and raw material changeovers

5 / Heat, glue, carton and film optimisation

Recommend Products

About King Machine

About King Machine

1 / Standardized workshop of total 20,000 square meters.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

2 / The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline,and pneumatic, electrical and mechnical stability.

3 / Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

King Machine Factory

<1> Standardized workshop of total 20000 square meters.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier &Korea Daewoo, ensure the precision of parts.

Different types of processing units, such as water jet cutter, plasma cutter, laser cutter, CNC machine from Taiwan chevalier &Korea Daewoo, ensure the precision of parts.

<2>The equipment will be tested and run for 24 hours before leaving the factory, to ensure the smooth working of water pipeline, and pneumatic, electrical and mechanical stability.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

<3>Sufficient stock of spare parts ensures the timely delivery and supply of spare parts.

<4>Engineers are experienced. We can produce different products with different capacity and work out reasonable flow chart as per customers’ requirements to save space.

<5>Professional installation team who can speak fluent English can help customers make benefits in a shortest time.

Certificate &Patent

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in King machine .

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark

registration,etc.

King Machine Serivce

*7/24 Online Service::Machine running video / Watch our factory online / More service contact us

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

*Sucessful Beverage Plant::Supply a running beverage line in your country , you can see machine runing directly.

*Installation / Debug / Training:

1 - We will arrange seasoned technician for equipments installation, debug and test production.

2 - Our company offers technology training to the customer in his factory.

3 - We promise that our goods are all new and not used.

*After-sales Service:

1 - After checking, we offer 12 months as a quality guarantee, free offer wearing parts and offer other parts at the lowest price.

2 - If you could not solve the problems, we will arrange a technician to your factory solving the problems.

3 - After quality guarantee, we offer technical support and after-sales service.

Customers Feedback

King Machine is a professional manufacturer of beverage machinery in China.With the scientific progressive conception of rapid

introduction, we make our machinery cover all over the overseas market. We have been producing our goods with mature techniques and first-class quality. We warmly welcome customers all over the world to visit our manufacture.

Customer Reviews

Cooperative Customer Brands

FAQ

HOW TO FIND KING MACHINE?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send King Machine an request and tell your basic inquiry

● King Machine sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to King Machine site

● The meaning of visiting supplier, because seeing is believing, King Machine with own manufacture and developed& research team,we

can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE KING MACHINE HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to

ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF KING MACHINE!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or

instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the

customers' project.

Hot Searches