- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CNMI

-

Model Number:

-

BL130

-

Type:

-

Composite Epoxy Resin

-

Technology:

-

Pultrusion

-

Viscosity:

-

Low Viscosity

-

Working time:

-

8 Hours

-

TG:

-

110-240

-

Mix Viscosity:

-

800-1100

-

Application:

-

Fiberglass Reinforcement Bar

-

Mixing Ratio:

-

2:1

-

Pultrusion Speed:

-

Excellent

-

Shelf life:

-

24 Months

-

Delivery Time:

-

3-5 Working Days

Quick Details

-

CAS No.:

-

25068-38-6

-

Other Names:

-

Epoxy Resin for Fiberglass Reinforcement Bar

-

Place of Origin:

-

China

-

Brand Name:

-

CNMI

-

Model Number:

-

BL130

-

Type:

-

Composite Epoxy Resin

-

Technology:

-

Pultrusion

-

Viscosity:

-

Low Viscosity

-

Working time:

-

8 Hours

-

TG:

-

110-240

-

Mix Viscosity:

-

800-1100

-

Application:

-

Fiberglass Reinforcement Bar

-

Mixing Ratio:

-

2:1

-

Pultrusion Speed:

-

Excellent

-

Shelf life:

-

24 Months

-

Delivery Time:

-

3-5 Working Days

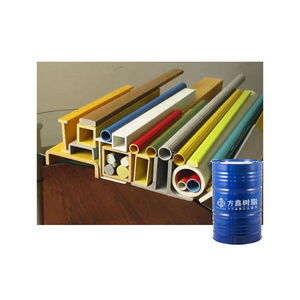

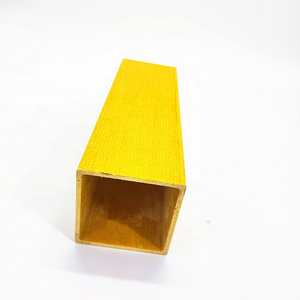

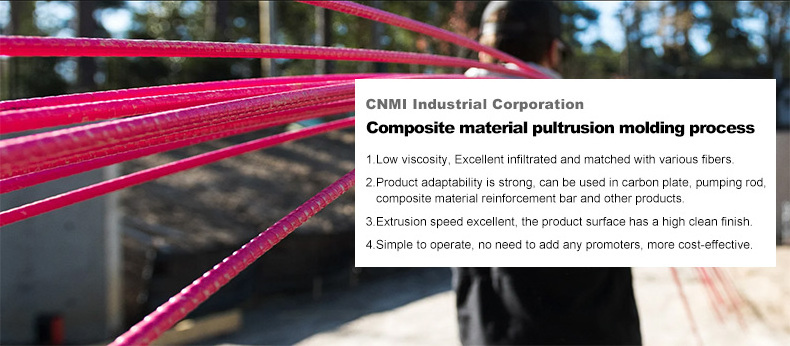

CNMI Epoxy Resin MTPHA DMP-30 Produce FRP Rebar GFRP Rebar FRP Fiberglass Reinforcement Bar High Temperature 200-240 Degree

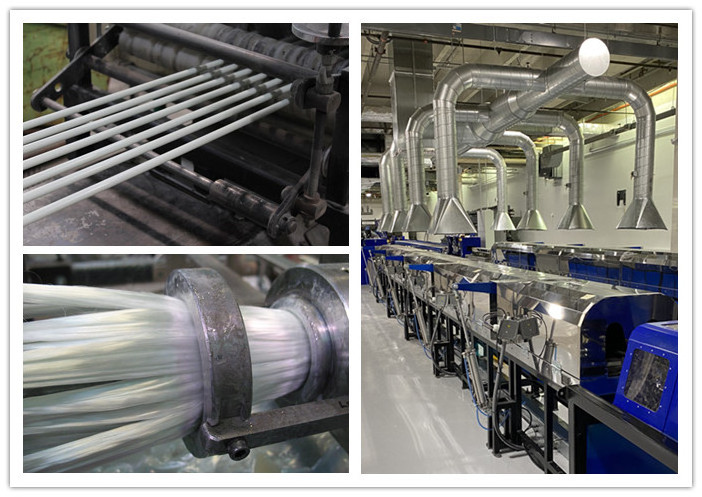

CNMI BL130 is designed for the pultrusion process and consists of epoxy resin BL130 -A and acid anhydride curing agent BL130 -B; the cured product has good chemical resistance, insulation and comprehensive mechanical strength. It is suitable for carbon fiber and glass fiber pultruded products, such as various insulating core rods, sleeves, special-shaped building structures and other materials.

Processing methods and conditions

For the traditional pultrusion molding process, the mold temperature can be selected from 130 to 210 degrees. The demolding time varies from 1-3 minutes according to the weight of the system material and the length of the mold. Three zone temperatures are recommended: 135±10℃, 1 75 ±10℃, 180±10℃. The demolding time and post-curing process should be optimized according to the production process.

|

Specification (1) |

Epoxy Resin |

BL130- A |

Standard |

||

|

Appearance |

Colorless or light yellow Liquid |

------- |

|||

|

Viscosity (mPa.s 25 ℃) |

5000-8000 |

Q/SH 1085 007-2020 |

|||

|

Density(g/cm3) |

1.1-1.2 |

Q/SH 1085 007-2020 |

|||

|

Hardener |

BL130-B |

Standard |

|||

|

Appearance |

Light yellow Liquid |

-------- |

|||

|

Viscosity (mPa.s 25 ℃) |

50-300 |

Q/SH 1085 007-2020 |

|||

|

Density(g/cm3) |

1.1-1.2 |

Q/SH 1085 007-2020 |

|||

|

P arameter |

|||||

|

Visosity after mixing (mPa.s ) |

BL130-A:BL130-B |

Standard |

|||

|

25 ℃ |

700-1000 |

Q/SH 1085 007-2020 |

|||

|

( 1 ) Note:Typical performance should not be considered as product specifications. |

|||||

|

Mixing and Processing |

The resin system shall be mixed in the following proportions |

||

|

BL130 |

BL130-A |

BL130-B |

|

|

By weight |

100 |

111 |

|