- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengXing leaching tank

-

Model Number:

-

SJ2000,SJ2500,3500

-

Dimension(L*W*H):

-

refer to different specifications

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001:2008,CE

-

application:

-

for gold ore cyanide leaching

-

drawing:

-

supply

-

Installation:

-

Engineer Guide

-

Mixer Type:

-

double impeller

-

Price:

-

Negotiable

-

After sale service:

-

Working Life

-

Effective Volume(m ):

-

2.2-31m3

-

colour:

-

as request

-

ore pulp density:

-

40-45%

-

name:

-

Gold Mine Machine Double Impeller Agitation Leaching Tank

Quick Details

-

Application:

-

Mining

-

Production Capacity:

-

99%

-

Power:

-

depending on different model

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HengXing leaching tank

-

Model Number:

-

SJ2000,SJ2500,3500

-

Dimension(L*W*H):

-

refer to different specifications

-

Warranty:

-

1 Year

-

Certification:

-

ISO9001:2008,CE

-

application:

-

for gold ore cyanide leaching

-

drawing:

-

supply

-

Installation:

-

Engineer Guide

-

Mixer Type:

-

double impeller

-

Price:

-

Negotiable

-

After sale service:

-

Working Life

-

Effective Volume(m ):

-

2.2-31m3

-

colour:

-

as request

-

ore pulp density:

-

40-45%

-

name:

-

Gold Mine Machine Double Impeller Agitation Leaching Tank

Energy Saving Agitation Leaching Tank For Mineral Ores :

Double-impeller leaching tank is a equipment used for gold cyanidation leaching process and absorption, two transmission ways, one is the planet-cycloid reducer drive; the other is the plane envelope reducer drive.

This equipment working conditions: pulp concentration ≤ 45%, pulp concentration ≤ 1.4 t / m .

so before the leaching tank ,will use thickener .

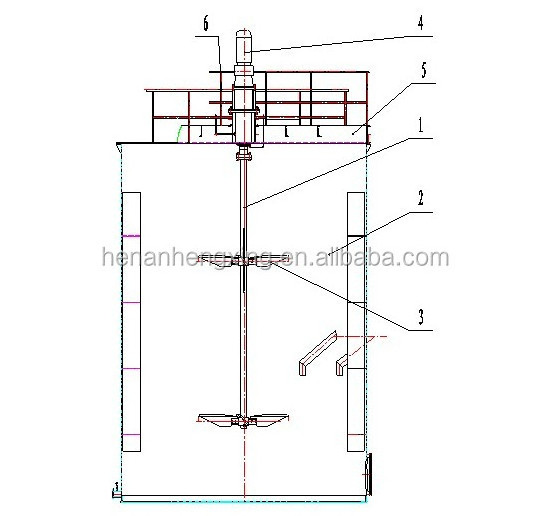

Double Impeller Leaching Tank Structure:

1. Vertical axis 2. Agitator 3. Impeller 4. Drive of motor 5. Beam 6. Railing

Leaching Tank Working Principle:

Double impeller leaching tank equipped with motor, cycloidal planetary gear speed reducer, bearing block and agitating shaft, is characterized by compact structure, little occupied space, and the agitating shaft equipped with a double impeller , from the top view the impeller rotating clockwise, each impeller composed of 4 blades, and the angle of the top blade and the below one is 45 degree. The compact air gets through the elbow pipe or the hollow shaft to the tank’s bottom, the raising air plays the role of mixing , at the same time the big bubble shattered by the impeller changing into small bubbles, in the end the pulp and air reaches fully mixing and sodium cyanide solution contacts with the pulp completely, thereby gets the better gold leaching result. The design of this device keeps the impeller low-speed moving, reducing the possibility of wearing or smashing the active carbon, so as to achieve high leaching rate, high absorption rate and collects more gold.

Leaching Tank Technical Parameters:

| Model |

Tank Specification

Diameter × Height (mm) |

Effective Volume

(m 3 ) |

Impeller Rotation Speed

(r.p.m) |

Impeller Diameter

(mm) |

Motor Power

(kw) |

Model of Planetary Cycloid Reducer |

Tank Weight

(kg) |

Total Weight

(kg) |

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2.2 | XLD2.2-4-29 | 1609 | 2144 |

| SJ2.5×3.15 | 2500×3150 | 13.14 | 52 | 935 | 2.2 | XLD2.2-4-29 | 2241 | 3095 |

| SJ3.0×3.0 | 3000×3000 | 18 | 40.85 | 1130 | 4 | XLD4-5-35 | 3391 | 4583 |

| SJ3×3.15 | 3000×3150 | 18.93 | 43 | 1130 | 4 | XLD4-5-35 | 2801 | 4160.6 |

| SJ3×3.5 | 3000×3500 | 21 | 43 | 1130 | 4 | XLD4-5-35 | 2975 | 4334.6 |

| SJ3.15×3.55 | 3150×3550 | 24 | 43 | 1260 | 4 | XLD4-5-35 | 3330 | 4322.8 |

| SJ3.5×3.5 | 3500×3500 | 30 | 52 | 1310 | 5.5 | XLD5.5-5-29 | 4286 | 5025 |

| SJ3.5×4 | 3500×4000 | 32.7 | 52 | 1310 | 5.5 | XLD5.5-5-29 | 4631 | 5429 |

| SJ3.55×4.0 | 3550×4000 | 33.6 | 43 | 1310 | 4 | XLD4-5-35 | 4060 | 5025 |

| SJ3.7×4.2 | 3700×4200 | 38.4 | 42 | 1310 | 4 | XLD4-5-43 | 5058 | 6153 |

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 7.5 | XLD7.5-7-43 | 6105 | 7569 |

| SJ4.5 ×5.0 | 4500×5000 | 71.57 | 35 | 1750 | 7.5 | XLD7.5-7-43 | 7506 | 10864 |

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 11 | XLD11-8-47 | 10482 | 14291 |

| SJ5.5×6.0 | 5500×6000 | 112 | 31 | 2100 | 11 | XLD11-8-47 | 14209 | 18745 |

| SJ6.5×7.0 | 6500×7000 | 195 | 21 | 2400 | 22 | XLD22-10-47 | 17890 | 26900 |

| SJ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 22 | XLD22-10-47 | 22090 | 29030 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 21 | 2900 | 18.5 | XLD22-10-47 | 24594 | 32796 |

| SJ8.0×8.5 | 8000×8500 | 342 | 18.5 | 3200 | 30 | XLD22-11-59 | 33489 | 42467 |

| SJ8.5×9.0 | 8500×9000 | 395 | 18.5 | 3300 | 30 | Y250-8 | 36696 | 46623 |

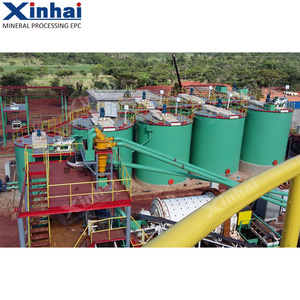

Double Impeller Leaching Tank For Gold Cyanide Leaching Process Production Site:

Contact:

Ms Sara Pang

Mobile phone : (whatsapp number): 0086137 8347 1727

Skype: sarapang6

Wechat: sarapang6