- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

6500*1500*1600mm

-

Weight:

-

9000 kg

-

Marketing Type:

-

New Product 2022

-

Frame Design:

-

Iron cast/steel plate

-

Roll Stations:

-

14-20 roller stations

-

Shafts Diameter:

-

70-80mm

-

Main Motor Power:

-

5.5kw

-

Hydraulic Power:

-

4kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC(detla) System

-

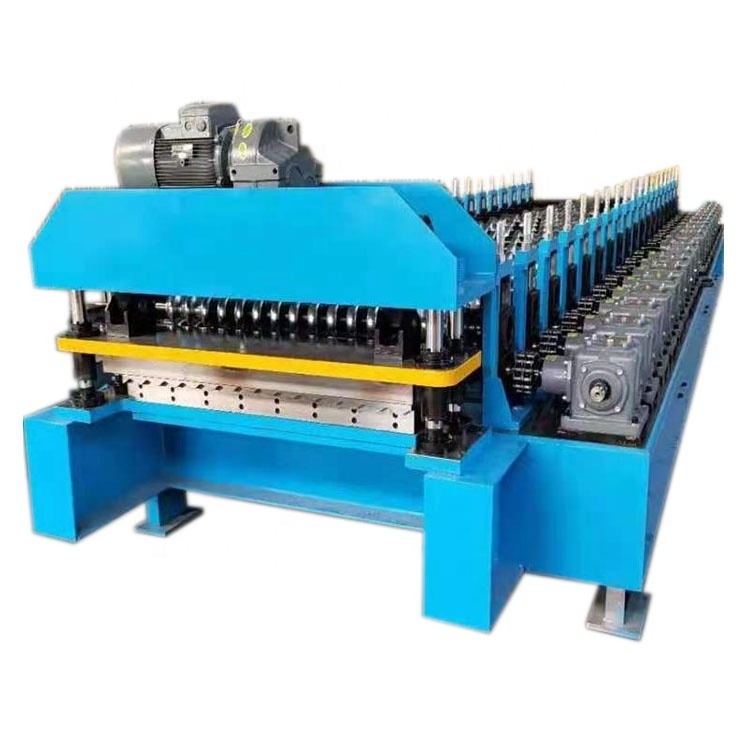

Machine Structure:

-

350H Steel Welding

-

machine frame:

-

iron cast

Quick Details

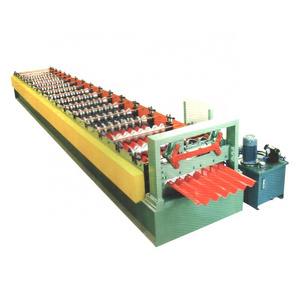

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Voltage:

-

380V 50Hz 3phases or as your requirement

-

Dimension(L*W*H):

-

6500*1500*1600mm

-

Weight:

-

9000 kg

-

Marketing Type:

-

New Product 2022

-

Frame Design:

-

Iron cast/steel plate

-

Roll Stations:

-

14-20 roller stations

-

Shafts Diameter:

-

70-80mm

-

Main Motor Power:

-

5.5kw

-

Hydraulic Power:

-

4kw

-

Material of Cutting Blade:

-

Cr12, Heat Treatment

-

Control System:

-

PLC(detla) System

-

Machine Structure:

-

350H Steel Welding

-

machine frame:

-

iron cast

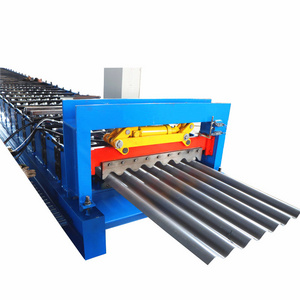

The advantages of our High speed high quality corrugated iron steel sheet roof sheet roll forming machine:

1.High speed:0-30m/min

2.Gearbox transmission for working more stable and improve the speed

3.Electric cutter which has no limit for the working temperature

4.Good quality and appearance.

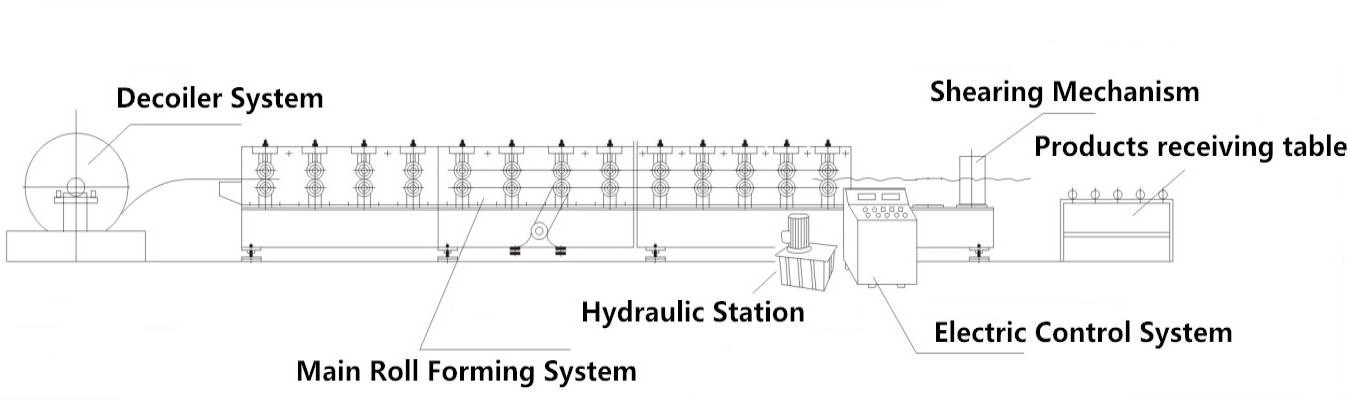

Work flow of production line

Uncoiler System:

Usage: It is used to support the steel coil and uncoil it in a turnable way.

Passive uncoil pulled by roll forming system

Loading capacity: 5 T

Uncoiling width: 1250 mm

Inner diameter: 450-550 mm

Quantity: 1 set

Entry Beach:

Usage: Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

Main Roll Forming System:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

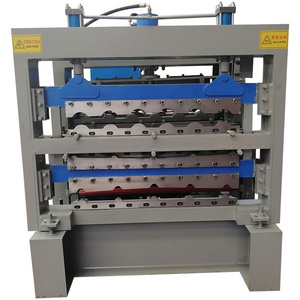

Shearing Mechanism:

Feature: Ensure stability, precision and cutting speed

It is used to make the step , the glazed tile's final formed.

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Function: Automatic cutting controlled by PLC

Material of blades : Cr 12 quenched

Power supply: Electric Motor

Components: It contains one set of blade, one hydraulic tank and one cutter machine.

Collecting Product Table

Left: Automatic Stacker (optional configuration)--Length: According to customized;

Right: Manual Simple collecting product table (standard configuration)--Length: 3m(common) or as customized.

Product Features

1. More efficient and accurate execution of production orders

;

2. High equipment reliability;

3. Little waste of materials and energy;

4. High productivity;

5. High quality materials, get a longer service life;

6. All parts of the machine are processed with precision, and the surface of the roll is chromeplated to ensure that customers can get qualified products at the same time, it can avoid the scratch of the color steel surface paint, and increase the service life of the roll;

7. Customized coil processing solutions to solve all aspects of technical problems.

Why Choose Us?

1) We have sold more than 5000 sets roll forming machines to many countries around the world.

2) We have hundreds of models about all kinds of roll forming machine for your reference, you donot worry of you do not have a profile drawing, We can recommond you some classical models that is common in your country.

3) When designing the macine, our considerate service will estimate and avoid the problem that may happen.

4) One set machine can provide many solutions with different price level.But they are all cost-effective.

5) We attach importance to many detailes,Every machine part quality is higher than our competitors in same price level.