- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Based

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

forging steel bar,rods,steel plate,nuts,bolts etc.

-

Input Current:

-

240A

-

Water Temperature Protection Point:

-

40 degree Room Temperature

-

Oscillating Frequency:

-

20-50khz

-

The flow rate of cooling water:

-

0.15 Mpa 25L/Min

-

Duty cycle:

-

100% full load,24hours of continuous work

-

Cooling method::

-

Water cooling machine

-

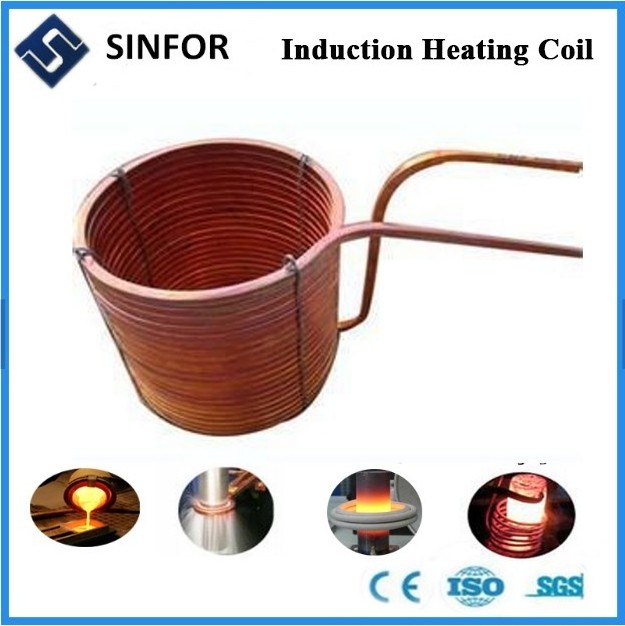

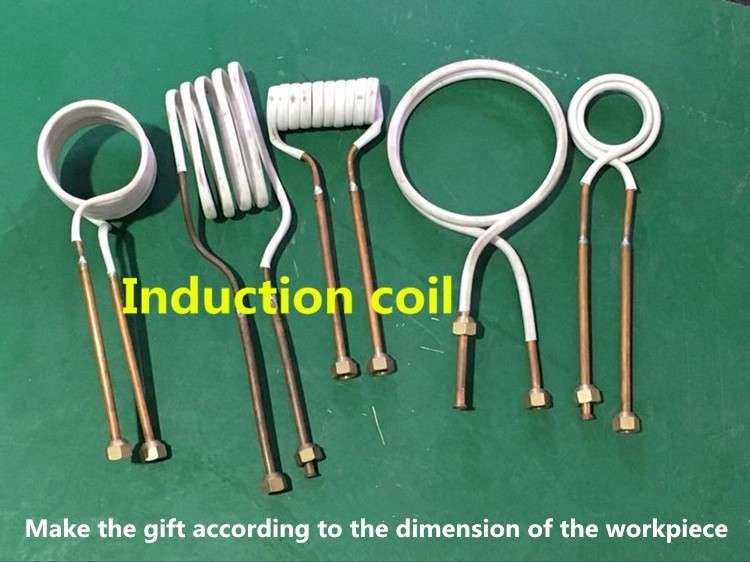

Heating element::

-

copper tube with insulating mate

-

Power Source::

-

Electric

-

Name::

-

induction copper heating coils

-

Certification:

-

ISO9001

Quick Details

-

Type:

-

Band Heater

-

Power Source:

-

Electric

-

Voltage:

-

12-480v/50-60HZ

-

Power:

-

Based

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

forging steel bar,rods,steel plate,nuts,bolts etc.

-

Input Current:

-

240A

-

Water Temperature Protection Point:

-

40 degree Room Temperature

-

Oscillating Frequency:

-

20-50khz

-

The flow rate of cooling water:

-

0.15 Mpa 25L/Min

-

Duty cycle:

-

100% full load,24hours of continuous work

-

Cooling method::

-

Water cooling machine

-

Heating element::

-

copper tube with insulating mate

-

Power Source::

-

Electric

-

Name::

-

induction copper heating coils

-

Certification:

-

ISO9001

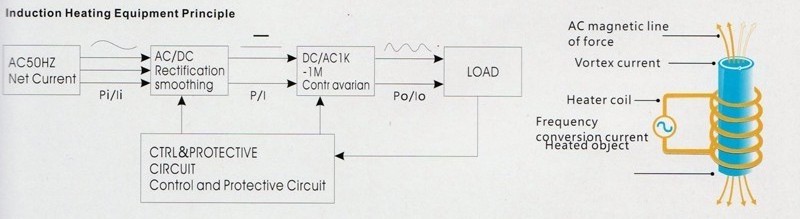

Main Features of

Induction bearing heater coil

1, The company transistor (IGBT) high frequency power-saving than vacuum tube up to 40-60%, saving 60%, external support facilities to reduce investment by 75%.

2, A unique cooling circulation system, ensure that the equipment 24 hours of continuous work.

3, Small size, light weight, easy to move, no million-volt high-voltage danger, safe operation.

4, High reliability, easy to maintain and improve the over voltage, over current, overheating, lack of, water and other self-protection.

5, The use of large scale integrated circuit digital automatic control, with manual, automatic, semi-automatic, and the lack of heat insulation of cold sub-time control functions.

6, The frequency of automatic tracking, stepless power adjustment, easy to use, 10 minutes to learn to use.

7,The company has a complete sales service system and the treatment of professional engineers, to ensure that you have no worry, no worry about technology.

Advantages of induction heating coil

1) No overall heating of the workpiece,it can be selectively localized heat, thus less power consumption, small deformation of the workpiece.

2) Fast heating, enhances the processing in a very short period of time to achieve the required temperature, or even 1 second. So that the workpiece surface oxidation and decarbonization are lighter, most of the artifacts are not gas.

3) The equipment needed by adjusting the operating frequency and power, the surface hardened layer of regulation. So that the hardened layer of fine martensite, hardness, strength and toughness are high.

4) After heat treatment by induction heating of the workpiece, the surface under a thick layer of hard toughness region, with better compression stress, fatigue and the workpiece are higher breaking capacity.

5) Heating equipment on the production line is easy to install, easy to implement mechanization and automation, ease of management, can effectively reduce the transport, saving manpower, increase production efficiency.

6) Multi-usage. Complete quenching, annealing, tempering, normalizing, quenching and other heat treatment process, but also complete welding, melting, hot assembly, disassembly and heat through hot forming and so on.

7) Easy to use, simple, open or stopped at any time. And without preheating.

8) Can be manually operated, but also semi-automatic and fully automatic operation; you can even continue working long hours can also be used to stop the random use. Equipment in power in favor of the use of low discount price.

9), High power utilization, environmental protection and energy saving, safe, reliable, good working conditions for workers.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.