- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DAWSON

-

Year:

-

New

-

Voltage:

-

440V/415V/380V/220V

-

Dimension(L*W*H):

-

11*7*7

-

Hollow part volume:

-

1200L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

88 kW

-

Extruder Motor Power(kW):

-

135 kW

-

Mold Platen Size(Width)(mm):

-

1800 mm

-

Mold Platen Size(Height)(mm):

-

1800 mm

-

Air Pressure(MPa):

-

0.7 MPa

-

Air Comsumption(m³/min):

-

2.2 m³/min

-

Die Head Heating Power(kW):

-

75 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

360

-

Weight (T):

-

65

-

Blow Molding Type:

-

Extrusion Blow Molding Machine

-

Die head type:

-

Accumulator type

-

Suitable IBC tank size:

-

500-1200L ibc bulk containers

-

Layer of IBC tank:

-

single layer, double layer, three layer available

-

Color changing time:

-

3 hours

-

Machine installation time:

-

one day

-

Language settings:

-

Chinese and English operation panel

-

Labor demand:

-

1~2 operator

-

Mold Material:

-

Aluminum profile

-

Mould Lifespan:

-

> 3,000,000 Cycles

Quick Details

-

Clamping Force (kN):

-

2200

-

Output (kg/h):

-

500 kg/h

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DAWSON

-

Year:

-

New

-

Voltage:

-

440V/415V/380V/220V

-

Dimension(L*W*H):

-

11*7*7

-

Hollow part volume:

-

1200L

-

Screw L/D Ratio:

-

30

-

Screw diameter (mm):

-

120 mm

-

Screw Heating Power(kW):

-

88 kW

-

Extruder Motor Power(kW):

-

135 kW

-

Mold Platen Size(Width)(mm):

-

1800 mm

-

Mold Platen Size(Height)(mm):

-

1800 mm

-

Air Pressure(MPa):

-

0.7 MPa

-

Air Comsumption(m³/min):

-

2.2 m³/min

-

Die Head Heating Power(kW):

-

75 kW

-

Accumulator Capacity(L):

-

50 L

-

Power (kW):

-

360

-

Weight (T):

-

65

-

Blow Molding Type:

-

Extrusion Blow Molding Machine

-

Die head type:

-

Accumulator type

-

Suitable IBC tank size:

-

500-1200L ibc bulk containers

-

Layer of IBC tank:

-

single layer, double layer, three layer available

-

Color changing time:

-

3 hours

-

Machine installation time:

-

one day

-

Language settings:

-

Chinese and English operation panel

-

Labor demand:

-

1~2 operator

-

Mold Material:

-

Aluminum profile

-

Mould Lifespan:

-

> 3,000,000 Cycles

Products Description

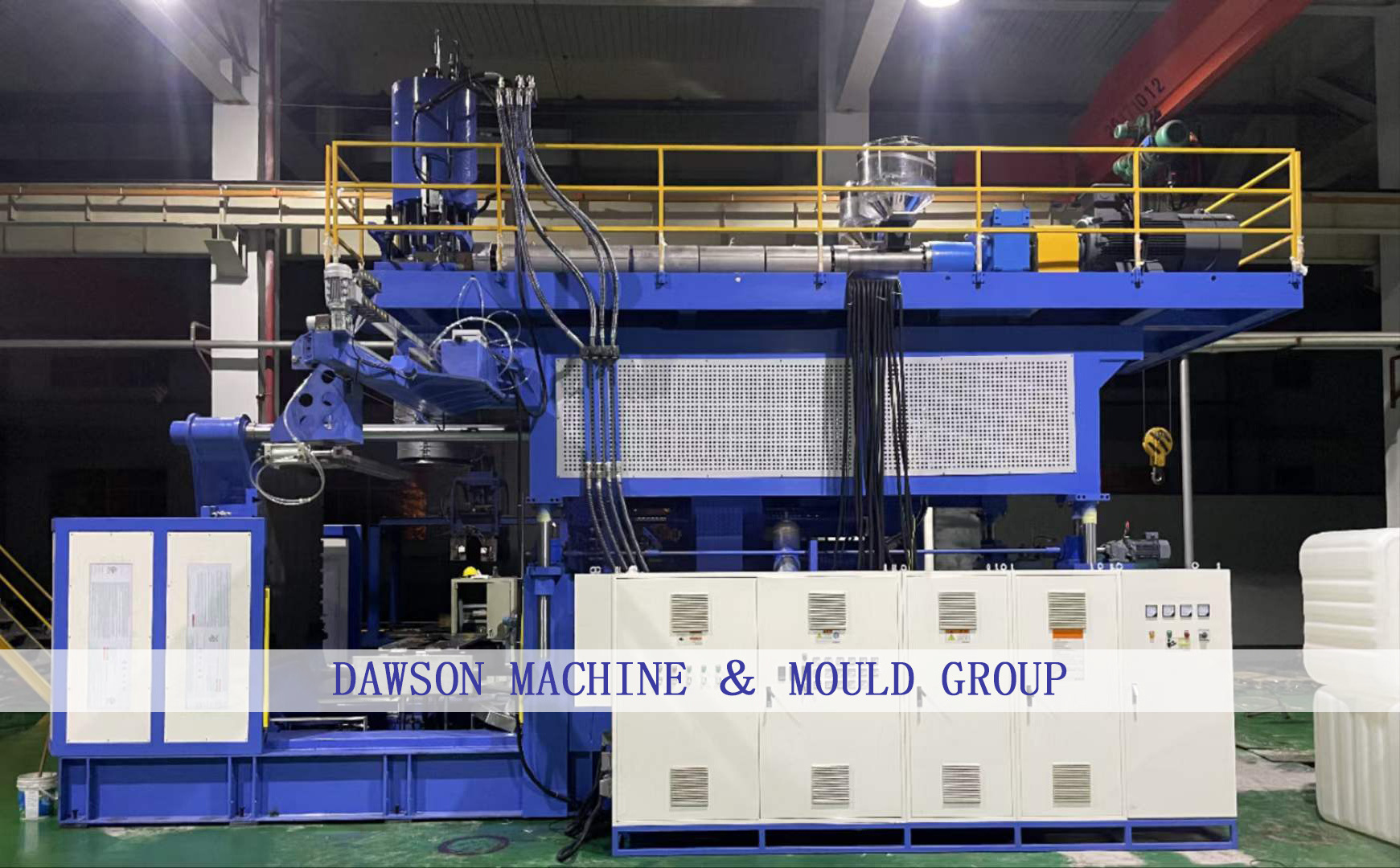

DAWSON MACHINERY & MOULD GROUP

1000L IBC Tank Inner Bottle Manufacturing Extrusion Blow Molding Machine

DMB-1000L extrusion blow molding machine is suitable for producing 500-1000L IBC Tanks. Equipped with special designed screw suitable for UHMWPE material, with uniform plastication, and no temperature rise, which shorten the IBC tank forming cycle. It’s production capacity can reach over 500pcs/day.

Manufacturing IBC tanks, changing color is a common procedure, using our special designed die head, you can shorten the color changing time, save power energy. One IBC tank use 8kw electricity.

The whole blow molding machine is equipped with bilingual operation panel and automatic configuration from world famous brands to realize the advantages of simple operation and high automation.

IBC tank 1000 liters also called 1000 litre plastic ibc bulk container is widely used in the chemical filling and transportation

fields. Compared with other round plastic drums, 1000 litre ibc container helps save more space in storage. And it can be recycled for many times. Multi-layers plastic ibc containers are also popular. The outer layer of the 1000l square plastic ibc tank can be with dark color, the blue ibc tank container and black ibc containers are to protect the liquid stored inside from light, to avoid the liquid going bad, and the inner layer using virgin material, will not pollute the stored content.

Our IBC tank specialized blow moulding machine, not only suitable for manufacturing ibc container 1000l, also suitable for

producing ibc tank 500 liters, just by changing the interchange part of 1000L ibc tank mould to 500l ibc container.

We have single layer, double layer & three layer plastic ibc tank blow moulding machine, the multi-layer plastic ibc tank blow moulding machine can meet your production demand for different application 1000l ibc inner bottle, whether you want to produce 1000 liter ibc for solvent, 1000l plastic ibc tank food grade, 1000ltr ibc container tank for water storage, ibc tank for ethanol and methanol, ibc tank for alcohol, ibc container for cooking oil, etc. Especially the three layers ibc production equipment extrusion machine, we can add the mixed material into the middle layer, virgin material to the inner layer and material with masterbatch for the outer layer.

We have supported customers for more than 50sets IBC inner bottle making machine, besides the HDPE plastic ibc tank manufacturing machine, we also provide ibc cage making machine, the equipments for the IBC container steel frame manufacturing.

Besides, we can provide the steel pipes, plastic ibc tank container fitting valves for different standard, types and applications.

Such as split type S60×6 Male thread ball valve, Integrated Type S60×6 Male Ball Valve, Welded Type S60×6 Male Ball Valve, Welded Type NPS Male Ball Valve, Integrated Type S60×6 Male Butterfly Valve, Split Type S60×6 Male Butterfly Valve, Welded Type S60×6 Male Butterfly Valve, we use PTFE material for the valve seat, because of PTFE material nonstick & anti-corrosive feature, enables the valve keep clean for sticky food grade liquid, and with longer lifespan. And for the thread valves, we use different material seal rings, there are EPDM, FKM and NBR material for different type of liquid. Besides the valves, we also have DN150mm, 6 Inch IBC inner tank normal cover and ventilation cover, ibc tank accessories, ibc tank fittings & ibc tank adapter.

fields. Compared with other round plastic drums, 1000 litre ibc container helps save more space in storage. And it can be recycled for many times. Multi-layers plastic ibc containers are also popular. The outer layer of the 1000l square plastic ibc tank can be with dark color, the blue ibc tank container and black ibc containers are to protect the liquid stored inside from light, to avoid the liquid going bad, and the inner layer using virgin material, will not pollute the stored content.

Our IBC tank specialized blow moulding machine, not only suitable for manufacturing ibc container 1000l, also suitable for

producing ibc tank 500 liters, just by changing the interchange part of 1000L ibc tank mould to 500l ibc container.

We have single layer, double layer & three layer plastic ibc tank blow moulding machine, the multi-layer plastic ibc tank blow moulding machine can meet your production demand for different application 1000l ibc inner bottle, whether you want to produce 1000 liter ibc for solvent, 1000l plastic ibc tank food grade, 1000ltr ibc container tank for water storage, ibc tank for ethanol and methanol, ibc tank for alcohol, ibc container for cooking oil, etc. Especially the three layers ibc production equipment extrusion machine, we can add the mixed material into the middle layer, virgin material to the inner layer and material with masterbatch for the outer layer.

We have supported customers for more than 50sets IBC inner bottle making machine, besides the HDPE plastic ibc tank manufacturing machine, we also provide ibc cage making machine, the equipments for the IBC container steel frame manufacturing.

Besides, we can provide the steel pipes, plastic ibc tank container fitting valves for different standard, types and applications.

Such as split type S60×6 Male thread ball valve, Integrated Type S60×6 Male Ball Valve, Welded Type S60×6 Male Ball Valve, Welded Type NPS Male Ball Valve, Integrated Type S60×6 Male Butterfly Valve, Split Type S60×6 Male Butterfly Valve, Welded Type S60×6 Male Butterfly Valve, we use PTFE material for the valve seat, because of PTFE material nonstick & anti-corrosive feature, enables the valve keep clean for sticky food grade liquid, and with longer lifespan. And for the thread valves, we use different material seal rings, there are EPDM, FKM and NBR material for different type of liquid. Besides the valves, we also have DN150mm, 6 Inch IBC inner tank normal cover and ventilation cover, ibc tank accessories, ibc tank fittings & ibc tank adapter.

|

Machine Model

|

|

Max. Bottle size

|

Production forecast

|

|

|

DMB-1000L

|

Single Station

Accumulator

Head

|

1200L

|

20-25 BPH

|

|

Technical Parameters

|

Name

|

Units

|

DMB-1000L

|

|

Max.product volume

|

L

|

1200L

|

|

Screw diameter

|

MM

|

120

|

|

Screw drive power

|

KW

|

132

|

|

Output of HDPE

|

KG/H

|

500-550

|

|

Oil pump drive power

|

KW

|

42

|

|

Clamping force

|

KN

|

2200

|

|

Max.size of mold

|

MM

|

1700× 1800

|

|

Template size

|

MM

|

1800×1800

|

|

Mold stroke

|

MM

|

1100-3300

|

|

Size of machine

|

L×W×H

|

11×7×7

|

|

Weight of machine

|

TON

|

65

|

Photos Reference

Clamping System

Customer Photos

Our professional blow molding machine workshop...

High Quality Blow Molding mould

In the process of plastic blow molding, the mold is a very important part. A good blow mould can make the product production more smoothly, and a good blowing mold can also make the finished product more flexible and beautiful.

We have our own mold production workshop, using high configuration equipment and mold engineers with 16 years of technical experience to customize blow molding mold for you.

- We use the best stainless steel S136H or Aluminium alloy 7075# as mould main material- Necking plate use JAPAN DC53 Heat treatment to HRC62

- Double neck design available to change in future as a spare part necking

- All mould can be made auto-deflashing or manual deflashing as per customer requests

- Perfect mould cooling design to ensure the best moulding preformace

- Available to provide 2D & 3D product drawing for customers

- Available to send samples to customer for approval the product quality

- We had already made moulds for TOTAL,SHELL,GULF,BMW,YAMAHA,MOBIL,TOYOTA,MENGNIU,

HYUNDAI,MENTHOLATUM,UNILEVER,LEE KUM KEE...

Hot Searches