- Product Details

- {{item.text}}

Quick Details

-

Power:

-

75KW

-

Dimension(L*W*H):

-

1.45*0.5*1.1m

-

Weight (KG):

-

8000

-

Product name:

-

Flat bar cold rolling mill

-

Brand:

-

HengYuan

-

Making speed:

-

3m/s

-

Weight:

-

7t

-

Size:

-

1.45*0.5*1.1m

-

Machine function:

-

Make ribble and reduce diameter

-

Raw materials' diameter:

-

6-12mm

-

Final product's diameter:

-

5-11mm

-

Working condition:

-

Stable and efficient

-

Color:

-

Customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hengyuan

-

Voltage:

-

380V 50HZ

-

Power:

-

75KW

-

Dimension(L*W*H):

-

1.45*0.5*1.1m

-

Weight (KG):

-

8000

-

Product name:

-

Flat bar cold rolling mill

-

Brand:

-

HengYuan

-

Making speed:

-

3m/s

-

Weight:

-

7t

-

Size:

-

1.45*0.5*1.1m

-

Machine function:

-

Make ribble and reduce diameter

-

Raw materials' diameter:

-

6-12mm

-

Final product's diameter:

-

5-11mm

-

Working condition:

-

Stable and efficient

-

Color:

-

Customized

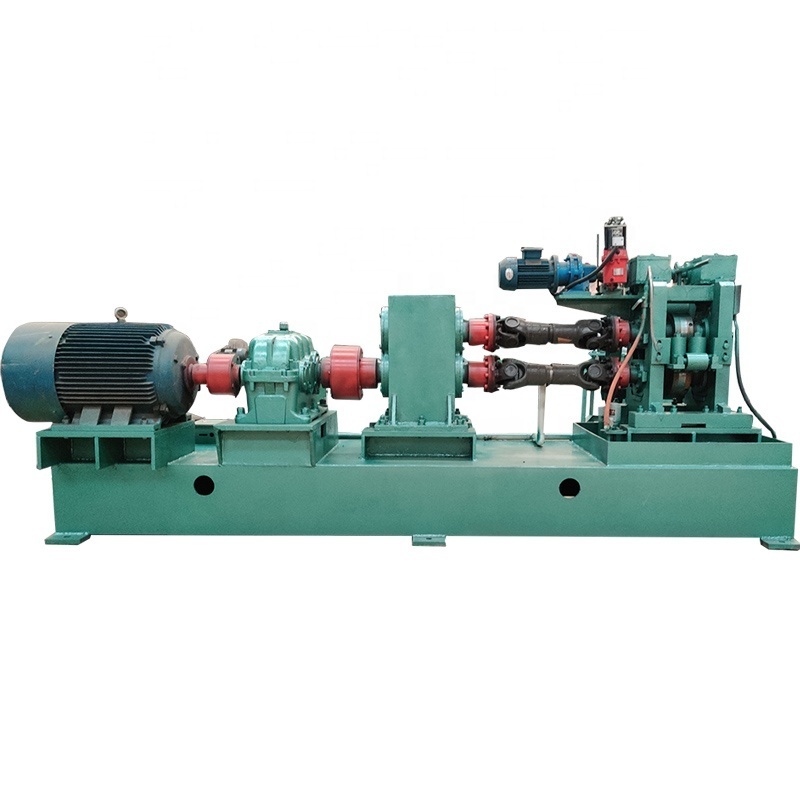

High quality flat bar cold rolling mill

cold roll formers machines

Short brief of flat bar cold rolling mill

This flat bar cold rolling mill is main part of 2 ribbed cold rolling automatic production line.

Through solid midfrequency heating, tensile strength of rebar can reach standard 400 Mpa , 500 Mpa and 600 Mpa.

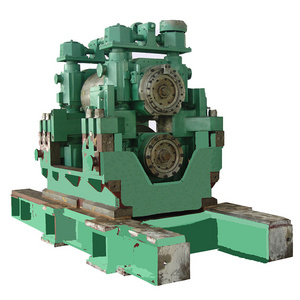

Main parts of the equipment for flat bar cold rolling mill

1.D erusting Machine

The machine is close type, there have three rotary wheels inside, we could adjust it up and

down, it is easier for the raw materials installation.

2. Rolling mill

The rollers’ angle should be 120°, at the same center, first rolling mill is mainly for reducing

the diameter, second set of rolling mill is for making the rebar.

3.Straigthen machine

This machine is mainly for reducing the machine hardness.

4.Fly shear

It is for cutting rebar after making rebar.

5. Automatic materials shaft

It is mainly for collecting rebar.

6.Jointing machine

Joint i ng machine is mainly for joining the two wire rod end together.

7.Electric Box

Control the whole working system.

Packaging & shipping for flat bar cold rolling mill

Plastic of flat bar cold rolling mill

Main spare parts of flat bar cold rolling mill Final product of flat bar cold rolling mill

FAQ

Q: How many types flat bar cold rolling mill do you have?

A: We have two main types:

1.Three ribs cold rolling mill

2.Two ribs cold rolling mill

Two ribs cold rolling mill is more expensive than three ribs.

Q: How about the capacity for flat bar cold rolling mill?

A: Capacity: 55T ---62T(10hours as one shift), when input size is 10mm.

Q: How many size for flat bar cold rolling mill?

A: Because we have two machine types for the flat bar cold rolling machine.

Machine type 285: i nput scope 8-16mm output scope 7-15mm

Machine type 228: i nput scope 6-12mm output scope 5-11mm

Q: Do you have any steel bar packing machine?

A: Yes, we have.

Our Service for flat bar cold rolling mill

We will send our engineer to customer area for installing and trainning. But customer should undertake engineer salary. Welcome to visi our factory, we will pick up you at our nearest airport, and provide our best service.

If you are interested in this flat bar cold rolling mill, please contact with me freely as the followings: