Products Details:Suspended ceiling t grid is made from hot dipped galvanized steel, pressed to T shape after cooling, baked paint on surface finish, it is suspension false ceiling consisting of the main tee, cross tee, and wall angle to make the grid system to support the lay-in ceiling tiles. Mostly applied in the public buildings such as office, hospital, classroom, airport and so on.

Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

projects

-

Design Style:

-

morden

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jintailong

-

Model Number:

-

JTL-S002

-

Product name:

-

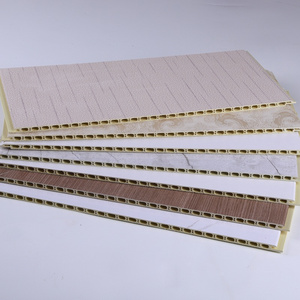

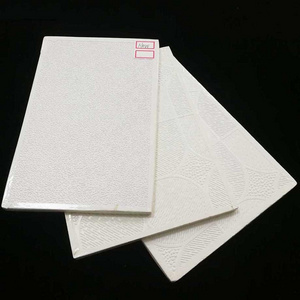

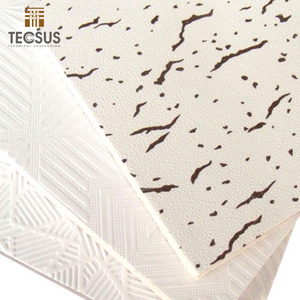

Pvc Gypsum Ceiling Board

-

Material:

-

gypsum powder

-

Usage:

-

Interior Decoration Materials

-

function:

-

home interior decorations

-

Surface:

-

Pvc Lamination Film

-

Color:

-

white or customized

-

Key word:

-

Suspended Ceiling Grid

-

Name:

-

Product Decorative PVC Gypsum Ceiling

-

Size:

-

595*595mm 603*603mm

-

Installation:

-

T-grid Galvanized Steel Keels

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

-

Application:

-

projects

-

Design Style:

-

morden

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jintailong

-

Model Number:

-

JTL-S002

-

Product name:

-

Pvc Gypsum Ceiling Board

-

Material:

-

gypsum powder

-

Usage:

-

Interior Decoration Materials

-

function:

-

home interior decorations

-

Surface:

-

Pvc Lamination Film

-

Color:

-

white or customized

-

Key word:

-

Suspended Ceiling Grid

-

Name:

-

Product Decorative PVC Gypsum Ceiling

-

Size:

-

595*595mm 603*603mm

-

Installation:

-

T-grid Galvanized Steel Keels

Product Description

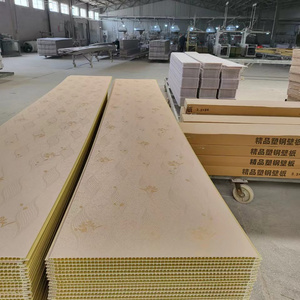

pvc gypsum ceiling In Yemen Gypsum Board Suspended Ceiling Panels Hot Selling PVC and Aluminum Foil Plasterboard Ceilings

we are a leading professional gypsum board manufacturer in china,we can provide all kinds of gypsum board as following:Standard gypsum board, Moisture-resistant gypsum board, Fire-proof gypsum board, Water-proof gypsum board ,PVC gypsum ceiling tile, Mineral fiber-board T-grids ,light keel steel ,self-tapping screw, paper joint tape, jointing compound and some other auxiliary material .

Specification

|

PVC Gypsum Board Ceiling

|

|

|

|

|

|

|

|

||||||

|

Material

|

Gypsum, Quartz Sand, Fiber

|

|

Bending Strength

|

≥187N

|

Surface Coating

|

PVC front side and

aluminum foil back side

|

|

||||||

|

Thickness

|

6.4-12mm

|

|

Impact Strength

|

≥472N

|

Usual Size

|

595~605*959~1210

|

|

||||||

|

Tolerance

|

Length

|

2mm

|

Density

|

9.2kg/m2

|

Moisture Rate

|

≤1%

|

|

||||||

|

|

Width

|

3mm

|

Coefficient of Thermal Expansion

|

≤5x106m/m.k

|

Strength

|

≥150N

|

|

||||||

|

|

Thickness

|

0.2mm

|

Coefficient of Moisture Expansion

|

≤0.20%

|

Unit Weight

|

≤7kg/sqm

|

|

||||||

|

|

Non uniformity of Thickness

|

≤8%

|

Coefficient of Drying Expansion

|

≤6*106

|

Packing

|

6,8 or 10 pieces per carton

with film

|

|

||||||

|

|

Edge Straightness

|

≤1.5mm

|

Thermal Conductivity

|

≤0.1%

|

Sagging resistant properities

|

Warranty against visible

sag

|

|

||||||

|

|

Surface planeness

|

≤2mm

|

Radioactivity

|

<1.0L

|

Noise reduction coefficient

|

0.1-0.3

|

|

||||||

|

|

Squareness

|

≤2mm

|

Nonflammable

|

Class A

|

Thermal conductivity

|

Resistant to 95% humidity

and standing water

|

|

||||||

|

100% asbestos free

|

|

|

|

|

Light reflectance

|

0.75

|

|

||||||

Features

A.Type:

1. Regular Gypsum Board

2. Fire proof Gypsum Board

3. Water-resistance Gypsum Board

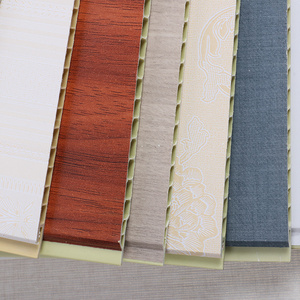

B.Color of the surface protection paper:

white-usually for standard gypsum board

red-usually for fire-resistant gypsum board

green-usually for moisture proof gypsum board

C.Features:

1) Non-absorbent, fire retardant and self-extinguishing

2) Weather proof, vandal proof, can be shaped, molded, painted and screen printed

3) Non-corrosive, non-toxic and chemical resistant

4) Tough, rigid with high impact strength

5) Non-warping and stain ;proof

D.Performance

1 Aging proofing

2. Frost resistance

3 Light weight

4 Environment friendly

E.Application

Hotel, Restaurant, Office, Station, Shopping Hall and private home of Ceiling, Partition and Dry lining wall

A.Type:

1. Regular Gypsum Board

2. Fire proof Gypsum Board

3. Water-resistance Gypsum Board

B.Color of the surface protection paper:

white-usually for standard gypsum board

red-usually for fire-resistant gypsum board

green-usually for moisture proof gypsum board

C.Features:

1) Non-absorbent, fire retardant and self-extinguishing

2) Weather proof, vandal proof, can be shaped, molded, painted and screen printed

3) Non-corrosive, non-toxic and chemical resistant

4) Tough, rigid with high impact strength

5) Non-warping and stain ;proof

D.Performance

1 Aging proofing

2. Frost resistance

3 Light weight

4 Environment friendly

E.Application

Hotel, Restaurant, Office, Station, Shopping Hall and private home of Ceiling, Partition and Dry lining wall

1) Surface: Imported or domestic PVC Film. / Painting

2) Back: Aluminium foil /Non-woven fabric

3)Edge: square and Fell level

4).Environment protection product: Adopting natural gypsum material free of any harmful material.

5).Non-flammable B1, in accordance with Chinese standard GB8624-1997

6).Not deforming, not cracking: keeping integrity and sound insulation for long under normal changes of.

7).Light weight, convenient to transport.,Corrosion-resistant, Non-dust, Easy clean

2) Back: Aluminium foil /Non-woven fabric

3)Edge: square and Fell level

4).Environment protection product: Adopting natural gypsum material free of any harmful material.

5).Non-flammable B1, in accordance with Chinese standard GB8624-1997

6).Not deforming, not cracking: keeping integrity and sound insulation for long under normal changes of.

7).Light weight, convenient to transport.,Corrosion-resistant, Non-dust, Easy clean

Installation Instructions

Various styles White Ceiling t grid Components t bar suspended ceiling grid Fut t grid tiles paint keel ceiling frames 32/38

Step 1

: Construct a pair of T-braces from 2 X 4s about an inch longer than the distance from floor to ceiling. Nail 2 X 4s about 3 feet long to one end of each longer 2 X 4 to form the Ts. Alternately, adjustable T-braces can be rented.

Step 2: Cut drywall panels to size. Use a sharp utility knife along a straightedge to cut drywall. After you make the cut through the face paper, place the board over a length of 2 X 4 laid flat on the floor, or some other type of support, and snap the scored section down. The gypsum core will break along the line you cut. Then turn the panel over, cut the paper on the other side, and smooth the rough edges with very coarse sandpaper on a sanding block.

Step 3: Install drywall panels on the ceiling. If possible, try to span the entire width with a single sheet of wallboard to

reduce the number of joints. Position and wedge the T-braces against the drywall sheet to hold it in place until you finish

nailing it.

Step 4: Drive nails at 6-inch intervals into all the joists covered by the sheet. Start in the center of the drywall panel and

work out. Give each nail an extra hammer blow to dimple the surface slightly without breaking the face paper.

Step 5: When the ceiling is finished, cut and install wall panels. Carefully measure for any cutouts in the drywall, including

electrical outlets, switches, or light fixtures. To make cutouts, draw a pattern of the cutout on the wallboard, drill a hole on

the pattern line, and then use a keyhole saw to follow the pattern.

Step 6: Space the nails 6 inches apart along studs, but start nailing 4 inches from the ceiling. Butt the wall panels against

ceiling sheets. Dimple all nails. Nail metal outside cornerbeads to cover any outside corners.

Step 2: Cut drywall panels to size. Use a sharp utility knife along a straightedge to cut drywall. After you make the cut through the face paper, place the board over a length of 2 X 4 laid flat on the floor, or some other type of support, and snap the scored section down. The gypsum core will break along the line you cut. Then turn the panel over, cut the paper on the other side, and smooth the rough edges with very coarse sandpaper on a sanding block.

Step 3: Install drywall panels on the ceiling. If possible, try to span the entire width with a single sheet of wallboard to

reduce the number of joints. Position and wedge the T-braces against the drywall sheet to hold it in place until you finish

nailing it.

Step 4: Drive nails at 6-inch intervals into all the joists covered by the sheet. Start in the center of the drywall panel and

work out. Give each nail an extra hammer blow to dimple the surface slightly without breaking the face paper.

Step 5: When the ceiling is finished, cut and install wall panels. Carefully measure for any cutouts in the drywall, including

electrical outlets, switches, or light fixtures. To make cutouts, draw a pattern of the cutout on the wallboard, drill a hole on

the pattern line, and then use a keyhole saw to follow the pattern.

Step 6: Space the nails 6 inches apart along studs, but start nailing 4 inches from the ceiling. Butt the wall panels against

ceiling sheets. Dimple all nails. Nail metal outside cornerbeads to cover any outside corners.

Packing & Delivery

Package: Carton with film

8 pcs/ paper box ,10 pcs/ paper box , 12 pcs / paper box or according to customer asking

8 pcs/ paper box ,10 pcs/ paper box , 12 pcs / paper box or according to customer asking

|

Normal Size

|

Thickness

|

SQM/20'

|

Gross Weight(KG)/20GP

|

Package

|

|

|

(mm)

|

|

|

|

|

595*595mm

|

7

|

4032

|

23600

|

Carton

|

|

600*600mm

|

7.5

|

3800

|

23800

|

with shrinking film

|

|

603*603mm

|

8

|

3600

|

23000

|

|

|

595*1195mm

|

8.5

|

3400

|

22800

|

10pcs/ctn

|

|

600*1200mm

|

9

|

3200

|

22600

|

|

|

603*1212mm

|

9.5

|

3000

|

22200

|

8pcs/ctn

|

|

|

10

|

2700

|

21800

|

|

|

|

12

|

2200

|

21800.00

|

|

Hot Searches