- Product Details

- {{item.text}}

Quick Details

-

Power:

-

100kw

-

Weight:

-

9000 KG

-

Dimension(L*W*H):

-

24mx2mx4m

-

Machine name:

-

bread crumbs snack food production line

-

Machine capacity1:

-

150-500kgs

-

Machine materials:

-

Stainless Steel Food Grade

-

Machine motors:

-

Siemens chinese brands

-

Machine frequency:

-

Delta

-

Application:

-

bread crumbs snack food production line

-

Raw materials:

-

wheat flour

-

Name:

-

bread crumb machine

-

Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SBN

-

Voltage:

-

380v/50hz

-

Power:

-

100kw

-

Weight:

-

9000 KG

-

Dimension(L*W*H):

-

24mx2mx4m

-

Machine name:

-

bread crumbs snack food production line

-

Machine capacity1:

-

150-500kgs

-

Machine materials:

-

Stainless Steel Food Grade

-

Machine motors:

-

Siemens chinese brands

-

Machine frequency:

-

Delta

-

Application:

-

bread crumbs snack food production line

-

Raw materials:

-

wheat flour

-

Name:

-

bread crumb machine

-

Service:

-

Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

Product description

1.Introduction:

Bread crumb processing line is researched and developed on the basis of international advanced technology.The perform-ance and quality have reached the highest domestic level of the same line.The line changes the traditional making process.From mixing materials,extruding,cutting,drying to finished products are done in one automatic line.The bread crumb is widely used as food coating additives on the surface of frying foods like:frying chincken,fish,sea foods,onion ring etc.The taste is fragrant,crispy,delious and with rich nutrition.

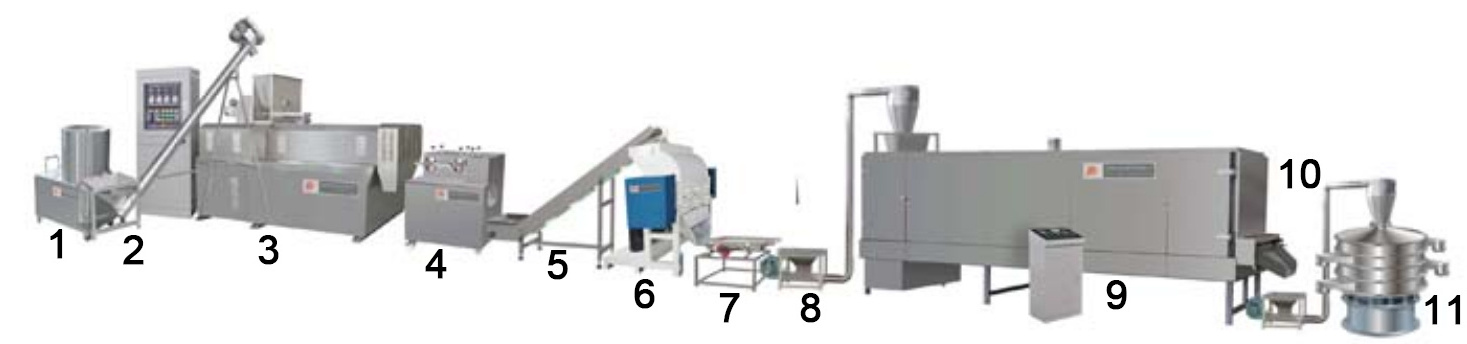

2.Flow chart:

Mixer--Extruder--Cutter--Humid crusher--Air conveyor--Dryer--Air conveyor--Classification sifter

3.Output:

120-150kg/h,200-250kg/h,450-500kg/h

4.Raw material:

wheat

5.Voltage in China:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries.

Sample

Manufacturing process

|

1

|

Mixer

|

It makes the powder raw materials and additives stirred(first step)

|

|

2

|

Screw conveyor

|

It conveys the mixed raw materials to extruder hopper directly.

|

|

3

|

Extruder

|

Raw material can be extruding different shape by the high temperature and high pressure and make the product safe.

|

|

4

|

Cutter

|

can be hauled to form the Continual strip-shaped, after shaping, it can become orderly, clean, and the right dimension.

|

|

5

|

Hoister

|

Transmit products to humid crusher

|

|

6

|

Humid crusher

|

Crush the finished products in small size.

|

|

7

|

Vibrate sifter

|

Remove the dust,the dust will not come into dryer.

|

|

8

|

Air conveyor

|

Transmit products to Dryer

|

|

9

|

Dryer

|

The heating way is electricity heating. It is used to bake and dry food.

|

|

10

|

Air conveyor

|

Transmit products to classification sifter

|

|

11

|

Classification sifter

|

Classification according to different sizes of products

|

Real machine in our factory

Technical parameter

|

Model

|

Installed power

|

Power consumption

|

Output

|

Size

|

|

SLG65

|

58KW

|

38KW

|

120-150kg/h

|

20000x1200x2200mm

|

|

SLG70

|

70KW

|

50KW

|

200-250kg/h

|

22000x1500x2200mm

|

|

SLG85

|

130KW

|

85KW

|

450-500kg/h

|

24000x1500x3500mm

|

Packing & Delivery

wooden packet or according to your desire for bread crumbs snack food production line

Hot Searches