- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

YUSEN

-

Model Number:

-

YUS-C115

-

Brand:

-

Yusen

-

Function:

-

Industrial

-

Size:

-

0.01mm~10mm

-

End types:

-

Custom

-

Surface treatment:

-

Zinc-plated, nickel-plated

-

ODM / OEM:

-

Available

-

Use:

-

Industrial

Quick Details

-

Style:

-

Spiral

-

Material:

-

Steel

-

Usage:

-

Industrial

-

Place of Origin:

-

Guangdong, China, Guangdong, China

-

Brand Name:

-

YUSEN

-

Model Number:

-

YUS-C115

-

Brand:

-

Yusen

-

Function:

-

Industrial

-

Size:

-

0.01mm~10mm

-

End types:

-

Custom

-

Surface treatment:

-

Zinc-plated, nickel-plated

-

ODM / OEM:

-

Available

-

Use:

-

Industrial

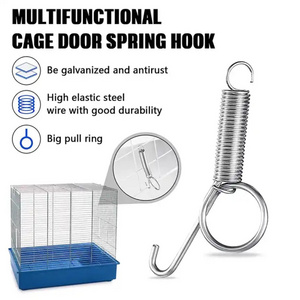

Products Description

Cage Door Spring Specification

Cage Door Spring 60mm

Material: spring steel

Surface Treatment: zinc plating

Total Length: 60mm

Cage Door Spring 70mm

Material: spring steel

Surface Treatment: zinc plating

Total Length: 70mm

Surface Treatment: zinc plating

Total Length: 70mm

Cage Door Spring 85mm

Material: spring steel

Surface Treatment: zinc plating

Total Length: 85mm

Surface Treatment: zinc plating

Total Length: 85mm

Cage Door Spring 115mm

Material: spring steel

Surface Treatment: zinc plating

Total Length: 115mm

Surface Treatment: zinc plating

Total Length: 115mm

|

S

PECIFICATION:

|

|

|

|

Material

|

stainless steel, carbon steel, spring steel, alloy spring steel, refractory steel, brass, metal, bronze, etc.

|

|

|

Wire Diameter

|

0.01~10.0mm

|

|

|

Finish

|

zinc, nickel, chrome, silver, gold, imitation gold plating or as request

|

|

|

Style of Ends

|

circle shackle/single shackle/side pull tab/extension retractor

|

|

|

Load

|

our computer program can assist you based on the load design

|

|

|

OEM & ODM

|

acceptable

|

|

FAQ

On this page, we have attempted to give you a short explanation of the terminology that is used to describe our springs, their technical characteristics and their features.

Q:

I

don't k

now about springs, how can I describe to you what I need?

---S

end us your design drawing, samples or design concept draft, after that we will assess your products and budget unit price for you.

Q:

How do

I ensure

that my

data is

protected and secured?

---We can sign a non-disclosure agreement with the client and a non-disclosure bond with our staff. We will never distribute any client information or data without the prior written consent of the client except to the extent required for execution of the project.

Q: In what format can the drawings be sent?

---The files can be of any graphic format, such as TIFF, JPEG or PDF. Auto CAD drawings can also be emailed to us for 3D modeling and animations,

Q: Do you provide post sales support and modifications?

---Yes. We provide correction and modification services after sales upon request. Our team will work on correction, adding new content, modification and upgrading with new technologies.

Q: How do you deal with the defective products?

---For the defective products, we will analyze failures and discard those ones, and then upgrade process, reduce failure rate and improve product quality.

Q: How long will a spring last?

---A correctly designed spring, without any extraordinary stress will last indefinitely. Designing a spring based on its operating environment is necessary to increase the life of the spring. If the spring is in corrosive environment, or under extreme temperatures, the proper material must be used in the design of the spring. Using s stainless steel material, or putting a protective finish on the spring according to the elements involved will increase the life cycle of the spring.

Q: How do I know if a spring is left hand or right hand wound?

---The best way to determine the direction of the spring is to use your right index finger and lay it over the spring. If the end of the spring starts at the tip of your right index finger and proceed to wrap towards your palm, this is considered a right hand wound spring. On the contrary, a left hand wound spring would start at the tip of your left index finger and wrap towards your left palm.

Q: Dose it matter if a torsion spring is left or right hand would?

---Yes. A torsion spring should be coiled so that the spring would wind up as a load is applied. If the spring unwinds as a load is applied it should probably be coiled in the opposite direction.

Q: What is the proper deflection of a spring?

---Deflection refers to the distance a compression spring is compressed, the distance an extension spring in extended, and the distance a torsion spring is rotated. Every spring is designed with a certain amount of sage deflection. If a compression spring is compressed more than its safe deflection the spring will begin to take a set, and not to come back to its original height. If an extension spring is extended beyond its safe deflection the spring will begin to increase in length as it is returned to its original position. The same is the case with a torsion spring, if it is wound beyond its safe deflection it will take a set and not unwind to its original starting position.

Hot Searches