- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

81*4.1 M

-

Weight:

-

500 KG, 4000KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

customized

-

Key Machines:

-

Welding Machine

-

Product Type:

-

Trintfar

-

product name:

-

Panel Radiator Automatic Production Line

-

Reled capacity:

-

other

-

Certification:

-

ISO CE CCC

-

Current:

-

/

Quick Details

-

Machinery Capacity:

-

customized

-

Brand Name:

-

TRINTFAR

-

Year:

-

2022

-

Dimension(L*W*H):

-

81*4.1 M

-

Weight:

-

500 KG, 4000KG

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V

-

Power:

-

customized

-

Key Machines:

-

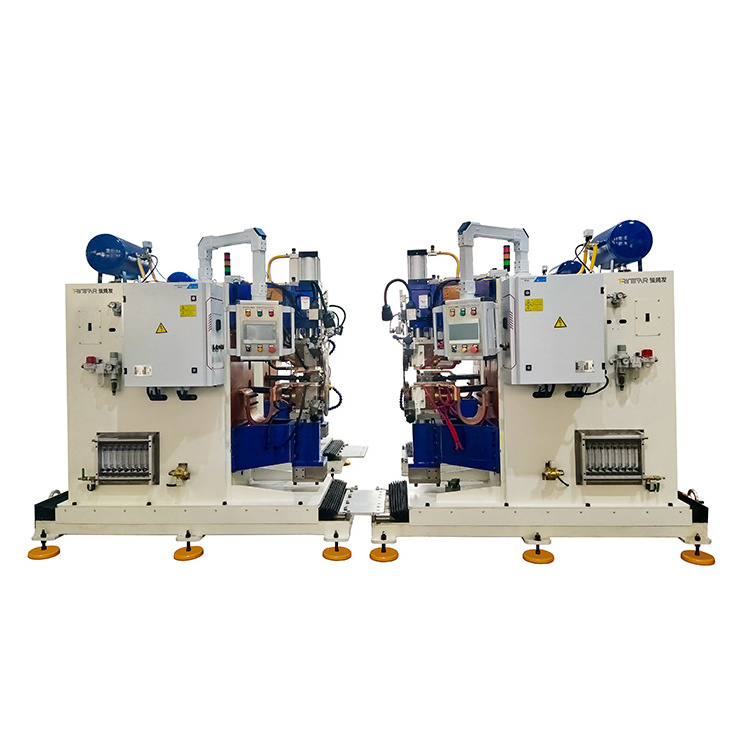

Welding Machine

-

Product Type:

-

Trintfar

-

product name:

-

Panel Radiator Automatic Production Line

-

Reled capacity:

-

other

-

Certification:

-

ISO CE CCC

-

Current:

-

/

Product Description

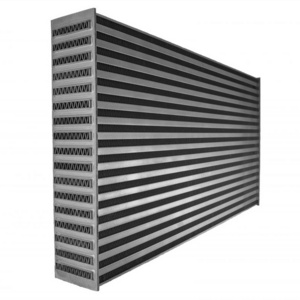

Panel

Radiator Automatic Production Line

We are offering as all our machines and production lines, this machine will also be customized according to your specific needs.It can be bought separately or together with our other production lines that will enable you to produce entire panel radiators for yourself

or your customers.

Support the proofing of welding products.

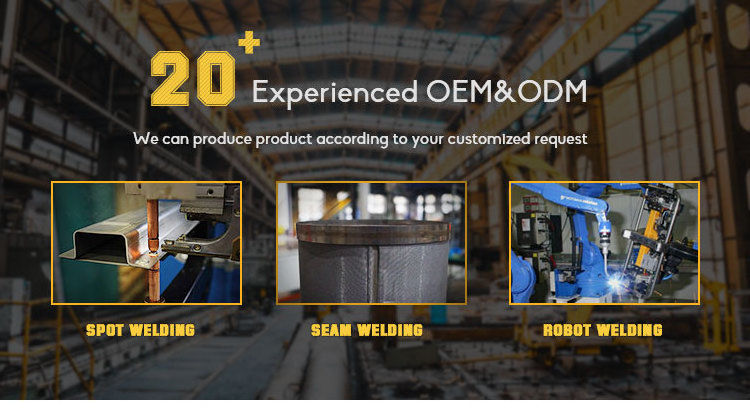

Customized service: We can design and develop welding machines according to your requirements. We have many welding design cases, including automatic welding production lines. We are an efficient and capable OEM supplier.

Welcome to consult.

|

Capacity configuration:

|

700 meters/day/8 hours

|

|

Operator:

|

4 people

|

|

Equipment area:

|

81*42 meters

|

|

Usage

|

Automatic Welding

|

|

Place of Origin:

|

Chnia

|

Feature:

·1.

Roll Form Press

Controlled by a precision servomotor, the Roll Form Press machine produces panels of variable length according to the chosen profile and end detail. Forming and feeding rollers work in combination with a press tool to form panels in a fully automated process.

· 2.

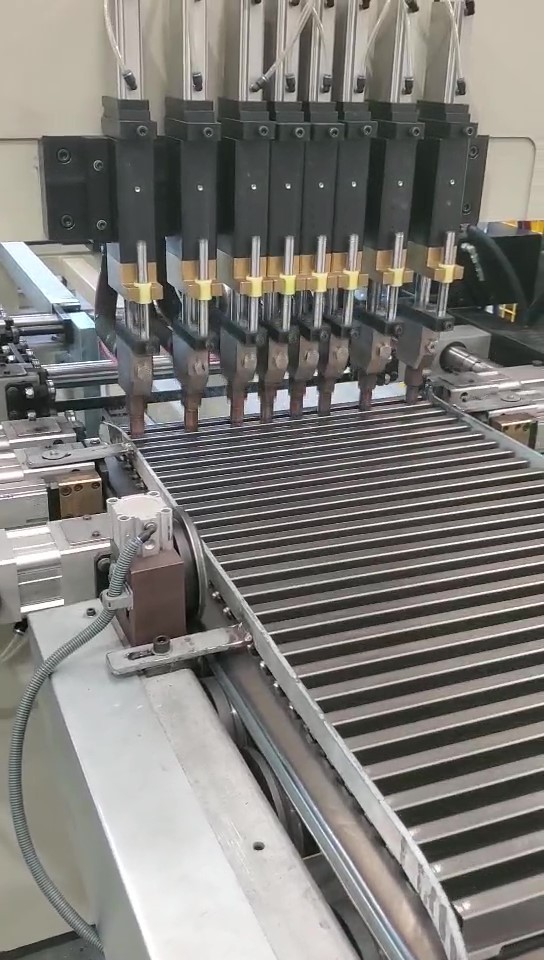

Multi-Spot Welder

The Multi-Spot Welder makes up to rows of spot welds along the ribs through the length of the panel. Software-controlled servo indexing of the panel assembly assures symmetrical positioning of spots for optimal pressure distribution.

· 3.

Seam Welder

The Seam Welder joins the edges of the panels through resistance welding. Each copper-welding wheel is internally cooled, without the need for an external water system.

As an automated solution, the seam is welded by dual welders for the longitudinal sides of the panel and by a third welder for the panel ends. As a manual solution, the operator controls the position of the panel relative to the welding wheels and rotates the panel in a single motion.

Related Products

Company Introduction

TRINTFAR in 1995, Trintfar is a high-tech enterprise of automatic welding equipment integrating scientific research, development, manufacturing and sales. As a national high-tech enterprise, after more than 20 years of unremitting efforts,

TRINTFAR has many cutting-edge welding technology products, including medium frequency, high frequency inverter resistance welding machine, numerical control resistance welding, laser welding equipment, automobile welding production line, welding robot integrated system, high speed steel drum seam welding machine, etc.

It is not only used in major automobile manufacturing and parts manufacturing enterprises, but also in aerospace, home appliance manufacturing, high-speed rail, low-voltage electrical appliances and other industries. The innovative team, excellent product design, advanced technology and reliable quality have made the TRINTFAR brand a reputation as a "reliable partner" in the welding equipment market at home and abroad.

Hot Searches