- Product Details

- {{item.text}}

Quick Details

-

Features:

-

heavyduty/energy saving/high cacity

-

Production Capacity:

-

500-7000kg/h

-

Dimension(L*W*H):

-

1200*200*250cm

-

Voltage:

-

220/380/415/440/480

-

Marketing Type:

-

New Product 2024

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Video Technical Support

-

Color:

-

Customer's Request

-

certification:

-

CE ISO

-

power:

-

35kw

-

Raw material:

-

multiple material

-

Advantage:

-

Low Consumption

-

controller:

-

PLC

-

Function:

-

High Efficiency Drying

-

Capacity:

-

500-7000kg/h

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

kx-machinery

-

Application:

-

sawdust/bagasse/rice husk/biomass waste, dry wet material

-

Features:

-

heavyduty/energy saving/high cacity

-

Production Capacity:

-

500-7000kg/h

-

Dimension(L*W*H):

-

1200*200*250cm

-

Voltage:

-

220/380/415/440/480

-

Marketing Type:

-

New Product 2024

-

Weight:

-

5000 KG

-

After-sales Service Provided:

-

Video Technical Support

-

Color:

-

Customer's Request

-

certification:

-

CE ISO

-

power:

-

35kw

-

Raw material:

-

multiple material

-

Advantage:

-

Low Consumption

-

controller:

-

PLC

-

Function:

-

High Efficiency Drying

-

Capacity:

-

500-7000kg/h

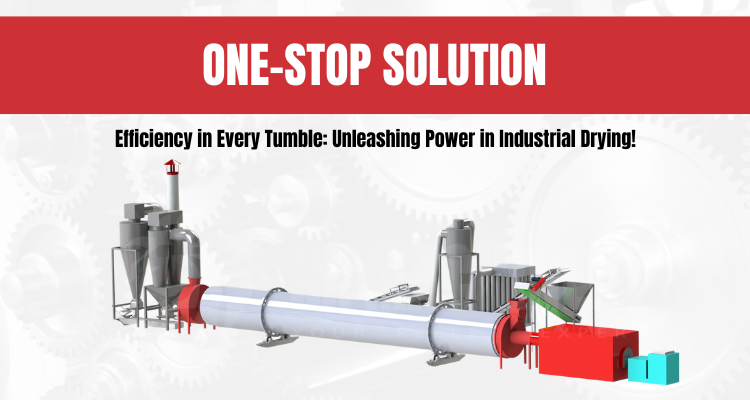

what is a drum dryer?

A

coco peat rotary dryer

is a type of drying equipment that is used to remove moisture from bulk materials, liquids, or slurries by tumbling them through a rotating cylindrical drum. This drum is heated internally, and the material to be dried is spread over its surface. As the drum rotates, the material comes into contact with the hot drum walls, and the moisture within it evaporates, leaving the dried product.

Wood chips rotary drum dryer

are commonly used in various industries for large-scale drying of materials such as grains, minerals, chemicals, food products, and more. The design of the drum dryer allows for efficient and uniform drying, as the rotation of the drum ensures that the material is constantly mixed and exposed to the heated surface.

There are different types of drum dryers, including single-drum dryers and double-drum dryers, each serving specific applications. Single drum dryers have a concentric inner drum and external shell, while double drum dryers have two drums that operate independently. The choice between these types depends on factors such as the nature of the material being dried, required throughput, and desired end product characteristics.

1. Precision Control Cabinet:

Take command of the drying process with our intuitive control cabinet. Seamlessly manage temperature settings, rotation speed, and other vital parameters, providing you with complete control over the drying operation.

2. Robust Drum Design:

The drum is the workhorse of our system, crafted from high-quality materials for durability and longevity. Its cylindrical form allows for efficient tumbling and even heat distribution across the material being dried. The large capacity of the drum accommodates substantial loads, ensuring optimal throughput and productivity.

3. High-Efficiency Hot Air Stove:

Our hot air stove is engineered for superior efficiency, delivering the necessary heat to the drum precisely. Achieve rapid and uniform drying through controlled and evenly distributed hot air. The stove's design emphasizes energy efficiency, minimizing operational costs while maximizing performance.

4. Cyclone Dust Removal System:

Maintain a clean and environmentally friendly workspace with our integrated cyclone dust removal system. As materials undergo drying, any entrained particles or dust are efficiently captured by the cyclone, ensuring a clean and safe operating environment. This system enhances the overall efficiency of the drying process while adhering to stringent environmental standards.

|

MODEL

|

CAPACITY

|

WEIGHT

|

POWER

|

|

KXDD-1800

|

3-5 T/H

|

25TON

|

30KW

|

|

KXDD1801

|

5-10 T/H

|

35TON

|

40KW

|

|

KXDD1801

|

11-14 T/H

|

40TON

|

45KW

|

Why choose us?

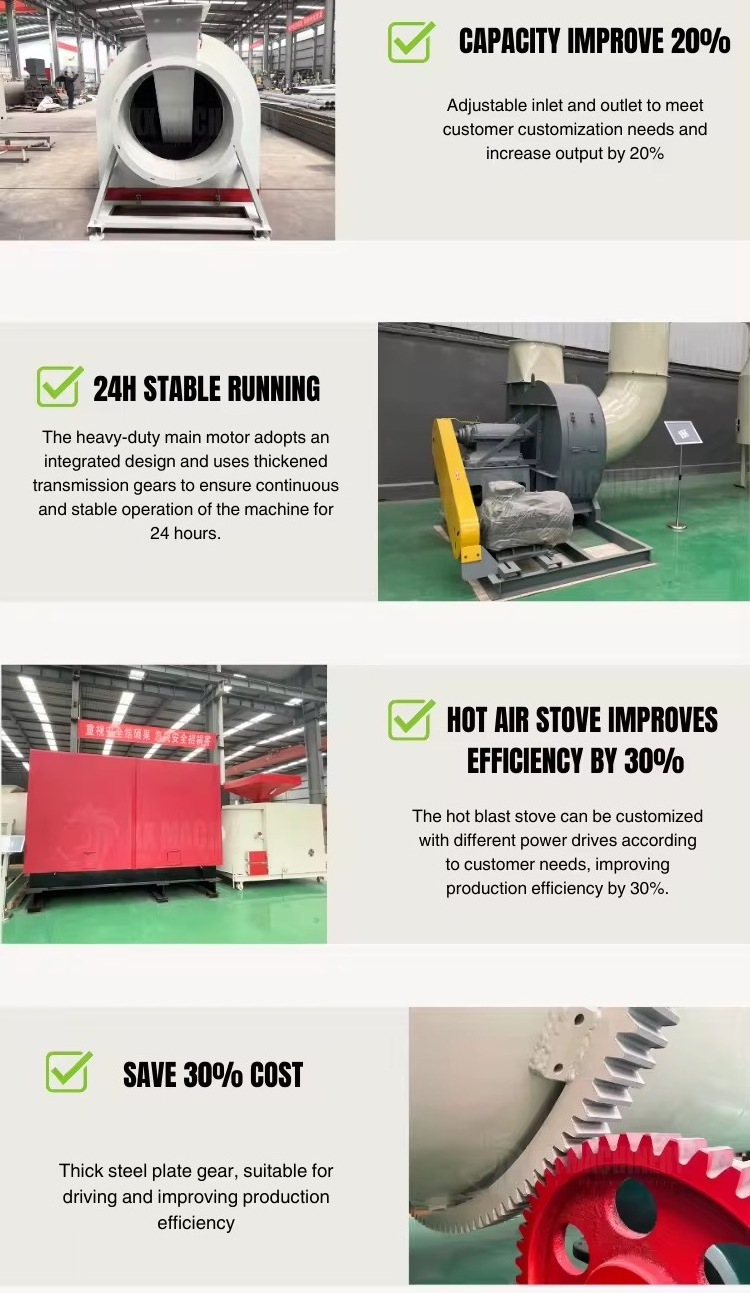

High Capacity Drum

: The heart of our dryer is its spacious drum, capable of accommodating substantial loads of laundry or other materials. This ensures optimal utilization of space and efficient drying.

Advanced Agitation System

: Our industrial dryer is equipped with a cutting-edge agitation system, guaranteeing uniform drying by preventing materials from clumping together. This results in consistently dry and evenly processed items.

Precision Temperature Control

: Tailor the drying process to your specific needs with our precision temperature control system. Achieve the ideal balance of heat for different materials, ensuring a gentle yet effective drying process.

Durable Construction

: Built with durability in mind, our industrial drum dryer is constructed from high-quality materials, capable of withstanding the rigors of heavy-duty usage. This ensures a long operational life and minimal maintenance requirements.

Energy-Efficient Design

: Save on operating costs with our energy-efficient design. The

wood sawdust dryer rotary drum dryer

is engineered to maximize drying efficiency while minimizing energy consumption, contributing to both cost savings and environmental sustainability.

1. Q: What biomass materials can be dried in

a coco peat rotary dryer

?

A: Various biomasses like wood chips, sawdust, and agricultural residues are suitable. Specific dryers cater to different biomass types.

2. Q: How efficient are

wood chips rotary drum dryers

?

A: Efficiency varies; factors include design, heat source, and moisture content. Choose a dryer that aligns with your biomass characteristics for optimal results.

3. Q: How do I control moisture levels in biomass using these dryers?

A: Adjust temperature and airflow settings to achieve desired moisture content. Regularly monitor and test biomass to ensure optimal drying results.

4. Q: How efficient are these dryers in terms of energy consumption?

A: Modern

wood sawdust dryer rotary drum dryers

often incorporate energy-efficient technologies, such as heat recovery systems, to optimize drying processes and reduce overall energy consumption.

Hot Searches