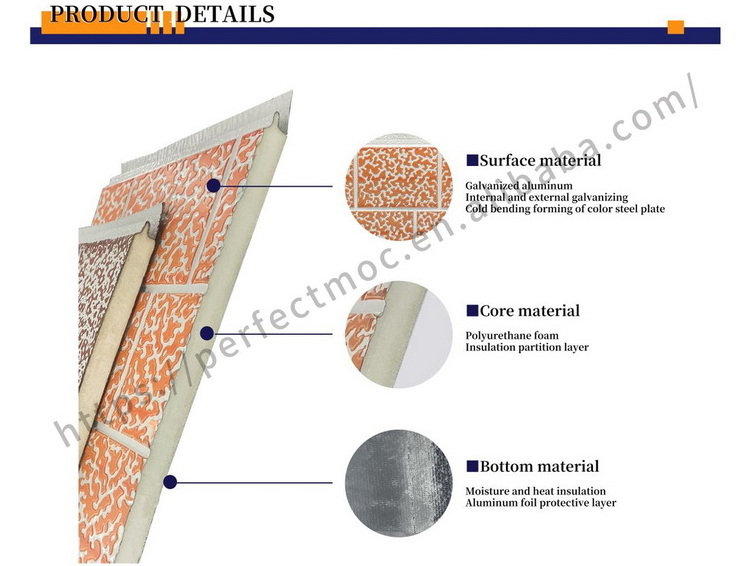

Rigid polyurethane foam is fireproof, flame retardant,and high-temperature resistant. After adding a flame retardant, polyurethane is a kind of flame retardant self-extinguishing material. Its softening point can reach more than 250 degrees Celsius, and it will decompose only at higher temperatures: in addition, polyurethane will burn in its foam when it burns. A carbon deposit forms on the surface, which helps insulate the foam below. Can effectively prevent the spread of flames. Moreover, polyurethane does not produce harmful gases at high temperatures.

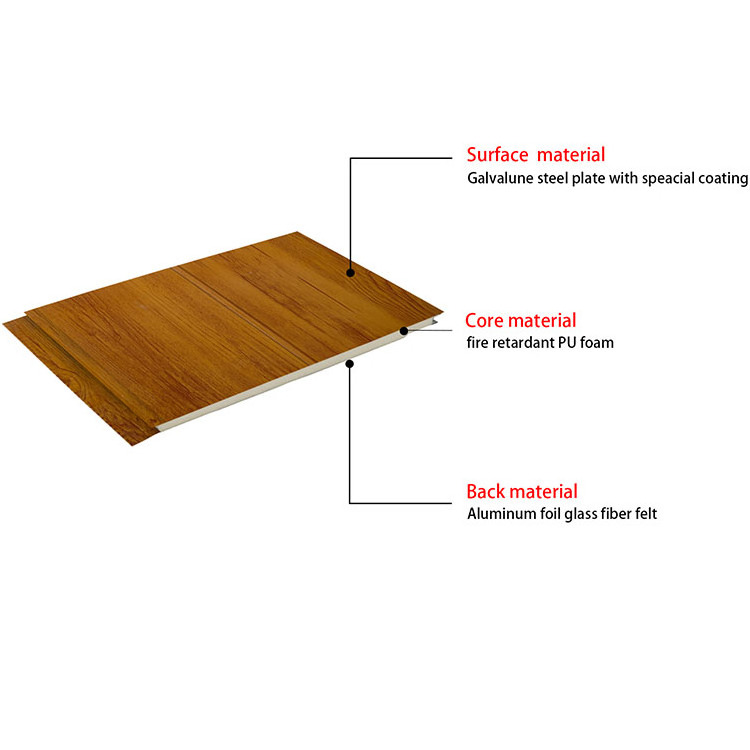

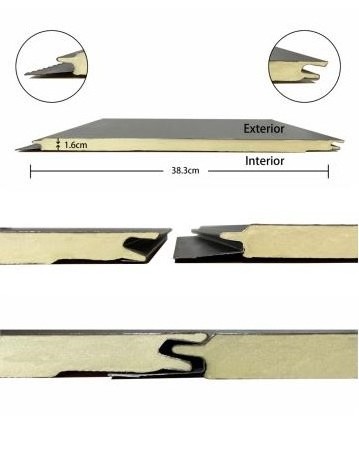

Polyurethane insulation panels are a cost-effective and efficient insulation material used in a variety of buildings. Their excellent insulation properties, durability, water resistance, and low maintenance make them popular in the construction industry. Additionally, their versatility means they can be used for both roof and wall insulation, providing a high level of thermal and sound insulation. The installation of PU panels is relatively simple and can be completed quickly, reducing installation time and costs. Overall, polyurethane insulation panels are an excellent option for building insulation, providing long-lasting protection against the elements.