- Product Details

- {{item.text}}

Quick Details

-

Power:

-

300000

-

Weight (KG):

-

6000

-

Commodity:

-

wire rod/section bar continuous casting and rolling production line

-

Advantages:

-

Large Output, High Efficiency

-

Final product:

-

Angel bar,rebar,wire rod,U steel,flat bar

-

Capacity:

-

1-40T/hour

-

After sales service provided:

-

Video technical support, Online support, Spare parts, etc

-

Certification:

-

ISO9001,CE

-

Rolling type:

-

Hot rolling mill

-

Inlet material:

-

Steel Scraps/Billets

-

Input:

-

380v,50hz

-

Feature:

-

Multifunctional

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Judian

-

Voltage:

-

380-400v

-

Power:

-

300000

-

Weight (KG):

-

6000

-

Commodity:

-

wire rod/section bar continuous casting and rolling production line

-

Advantages:

-

Large Output, High Efficiency

-

Final product:

-

Angel bar,rebar,wire rod,U steel,flat bar

-

Capacity:

-

1-40T/hour

-

After sales service provided:

-

Video technical support, Online support, Spare parts, etc

-

Certification:

-

ISO9001,CE

-

Rolling type:

-

Hot rolling mill

-

Inlet material:

-

Steel Scraps/Billets

-

Input:

-

380v,50hz

-

Feature:

-

Multifunctional

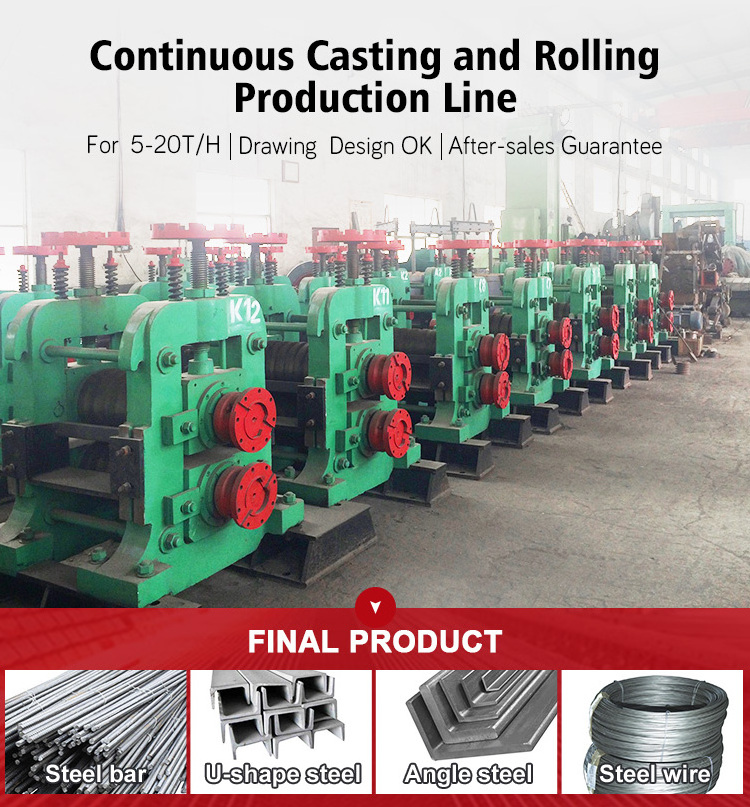

10mm continuous automatic Small steel rebar production line steel flat bar hot rolling mill machine rebar steel making machine

PRODUCT SHOW

Rolling Mill Continuous Production Line

1. The continuous rolling mill is an advanced method which can improve labor productivity and rolling type, mainly used in iron and steel plants to produce section bar, wire rod, steel bar, channel steel, flat bars, steel plates and other products. The raw material is steel scrap or billet (40-120mm).

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

1, Provide overall solution and after-sales guarantee.

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services.

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other

services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied.

5, Long-term technical support, long-term machine warranty.

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services.

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other

services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied.

5, Long-term technical support, long-term machine warranty.

DETAIL DISPLAY

1, By using metallurgical heat energy of continuous casting blanks, 30% of energy consumption can be saved.

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products.

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products.

SPECIFICATION

|

Specification and Technical Parameter

|

|

|

|

|

||||

|

Capacity(T/Hour)

|

Working hours(Year)

|

Electricity consumption

|

Feeding section

|

Rolling Specification

|

||||

|

5

|

2400

|

5MW

|

60*60mm

|

Φ6.5-32mm

|

||||

|

8

|

2400

|

8.5MW

|

70*70mm

|

Φ6.5-32mm

|

||||

|

10

|

3600

|

9.5MW

|

90*90mm

|

Φ6.5-32mm

|

||||

|

15

|

3600

|

10MW

|

120*120mm

|

Φ6.5-32mm

|

||||

|

20

|

6000

|

15MW

|

120*120mm

|

Φ6.5-32mm

|

||||

|

35

|

6000

|

26MW

|

150*150mm

|

Φ6.5-32mm

|

||||

RECOMMEND

ABOUT US

PACKING & DELIVERY

FEEDBACK

Hot Searches