- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200 KG

-

Name:

-

Stainless Steel Conical brewery fermenting equipment for sale

-

Heating method:

-

Electric /Steam heating /direct fire

-

Control system:

-

PLC Control with Siemens Screen / Pid Control

-

Milling System:

-

Stainless Steel Double Roller Grain Miller

-

Brewhouse System:

-

2 or 3 or 4 Vessels Brewhouse Type with Steam Jackets

-

Filling System:

-

Keg Machine, Bottling Lines, Canning Lines

-

Fermenting System:

-

Stainless Steel Conical Fermentation Tanks

-

Cleaning System:

-

CIP Trolly with Alkaili and Sterilize Tank

-

Cooling System:

-

Ice Water Tank with Glycol Chiller and Pumps

-

Capacity:

-

100L -30000L Turnkey Brewery System

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TONSEN

-

Voltage:

-

Request

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

Capacity Request

-

Weight:

-

200 KG

-

Name:

-

Stainless Steel Conical brewery fermenting equipment for sale

-

Heating method:

-

Electric /Steam heating /direct fire

-

Control system:

-

PLC Control with Siemens Screen / Pid Control

-

Milling System:

-

Stainless Steel Double Roller Grain Miller

-

Brewhouse System:

-

2 or 3 or 4 Vessels Brewhouse Type with Steam Jackets

-

Filling System:

-

Keg Machine, Bottling Lines, Canning Lines

-

Fermenting System:

-

Stainless Steel Conical Fermentation Tanks

-

Cleaning System:

-

CIP Trolly with Alkaili and Sterilize Tank

-

Cooling System:

-

Ice Water Tank with Glycol Chiller and Pumps

-

Capacity:

-

100L -30000L Turnkey Brewery System

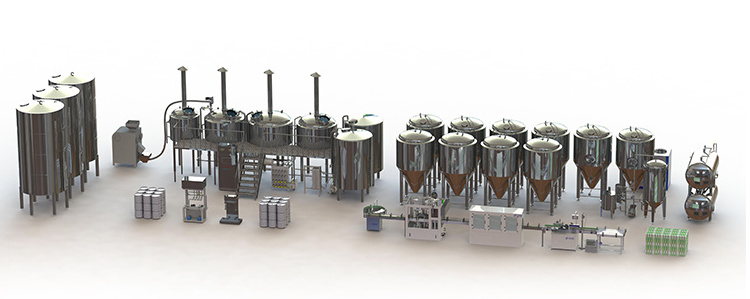

COMPETITIVE ADVANTAGE BREWERY EQUIPMENT FOR SALE

|

CRAFT BEER BREWING EQUIPMENT / MICRO BREWERY EQUIPMENT STAND SETUP LIST:

|

|

|

|

|||

|

|

Components

|

Specification

|

|

|||

|

Milling system

|

Flex Auger

|

Stainless steel

|

|

|||

|

|

Grist case

|

SUS304

|

|

|||

|

Milling System

|

Miller

|

Double Roller,Noise<60db

|

|

|||

|

Heating System

|

Boiler (steam heating)

|

Electric or steam or direct fire

|

|

|||

|

|

Mash / Lauter tun

|

Heating jacket

Material: SUS 304/316 or Red copper 1 Thermometer / tank |

|

|||

|

|

Boiling / Whirlpool Tank

|

|

|

|||

|

|

Heat-exchanger

|

Plate type

|

|

|||

|

|

Fermentation Tank

|

Top manway/Side manway , Glycol cooling jacket

|

|

|||

|

|

Yeast Adding Tank

|

SUS304 Stainless Steel

|

|

|||

|

|

Refrigerator machine

|

With control system

|

|

|||

|

|

Pump / valve

|

|

|

|||

|

|

Ice water tank

|

Fluorine filling

|

|

|||

|

CIP Cleaning System

|

Acid Tank

|

|

|

|||

|

|

Alkali Tank

|

|

|

|||

|

|

Pump

|

|

|

|||

|

Control System

|

Control Cabinet

|

Semi-automatic

|

|

|||

|

Filtering System

|

Candle type diatomite filter/Membrane filter/Bag filter

|

|

|

|||

|

|

Bright beer tank

|

Double-layer with insulation;

|

|

|||

|

Filling System

|

Glass bottle line

|

Manual/semi-auto/full auto type

|

|

|||

|

|

Canning line

|

Manual/semi-auto/full auto type

|

|

|||

|

|

Keg system

|

Manual/semi-auto/full auto type

|

|

|||

PRODUCT DETAILS

Fermentation tank/unitank/CCT/CKT details

*Dimple plate cooling jacket on tank body and conical bottom

*Insulation: polyurethane, thickness: 80mm

*Interior thickness: 3mm

*Exterior thickness: 2mm

*Dished head and taper angle 60°

*Temperature sensor TP100

*Side/top manway

*Inner tank mechanical polishing and out plate surface protection ribbon polished on welds

*1pcs x CO2 port with carbonation stone

*1pcs x Hops adding port

*1pcs x breathing valve

*1pcs x water sealed spunding valve

*1pcs x sample valve

*1pcs x racking arm

*1pcs x pressure gauge

*1pcs x CIP 360°spray device

*1pcs x drain outlet bottom

*4 heavy duty legs with leveling pad

*Max working pressure: 2bar

*Material: SUS304 outer shell. Interior Finish: Overall polishing ≤0.6μm,Completely acid washing and passivation without dead corner.Form a protection film inside tank.

Any special request for the tank, welcome to check with me directly!

Fermentation systems is made up of Fermentation Tank and Bright Beer Tank quantities are based on customer’s request. According to different fermenting request, structure of fermentation tank be be designed accordingly.Generally Fermentation Tank structure is dished head and cone bottom,with Polyurethane installation and dimple cooling jackets .There is a cooling jacket on tank cone section,columnar part has two or three cooling jackets.This not only can meet the relevant requirements of cooling, guarantee cooling rate of fermentation tank, also help to precipitation and storage the yeast.

Tank internal and external wall are made of international quality standards of sanitary 304 stainless steel,the Polyurethane insulation thickness between the inner and outer is 100-200mm.conic bottom install inlet and outlet pipes,valves,temperature transducer,etc,with the help of PLC auto-control, the equipment can reach to automatic and semi-automatic control. The height of conic bottom is a quarter of the total height.the ratio of tank diameter and height of tank is 1:2~1:4,the cone angle usually between 60°~90°.

Brewhouse system

Brew house system consists of Mash Tun, Lauter Tun, Boiling Kettle, Whirlpool kettle, Hop Dosing Equipment.The main equipment adopted international quality standards of sanitary 304 stainless steel,to deal with the tank by plasma cutting ,pure Ar-shielding welding,mechanized automatic polishing machine .

Our scientific Dimple Jacket production technology can utmost ground realizes the effect of heat conduction,use high quality rock wool or polyurethane materials to insulation for the inner tank,effectively prevent heat energy leakage from the tank.advanced Lauter Tun raker systems and automatic hydraulic lifting technology,can ensure mash filter uniform and comprehensive.

The brew house system could be included two-vessels brew house, three-vessels brew house and four-vessels brew house. Two-vessels brew house includes mash/lauter tun and kettle/whirlpool tank. Three-vessels includes mash tank, lauter tun and kettle/whirlpool tank. Four-vessels includes mash tank, lauter tun, boiling kettle and whirlpool tank. The capacity is bigger, the vessels is more. It is just in order to reduce the brewing time, improve the working efficiency.

The saccharification system heating has many forms, such as steam heating, electric heating pipe heating, direct fire heating, heat conducting oil heating and so on.

RELATED PRODUCTS

SHANDONG TONSEN EQUIPEMT CO., LTD

CONTACT US FOR MORE DETAILS AND EQUIPMENT!

ABOUT US

Shandong Tonsen Equipment Co., Ltd. was established in

2016

. It is a company specializing in the research and development, production, sales and technical support of beer equipment, liquor and fruit wine equipment, distillation and purification equipment, biological fermentation equipment, condiment equipment, kitchen waste treatment equipment, etc. An international comprehensive enterprise integrated with service. The company’s headquarters is located in Jinan City, Shandong Province, which is called “the Spring City of China”. Its own factory covers an area of nearly

20,000 square meters

. It has

80

front-line employees,

10

production management personnel,

5

top professional and technical personnel, and 10 management personnel. Over years of industry experience.

Tonsen Company takes the business tenet of respecting customers, serving customers, and creating value for customers, and unremittingly pays close attention to product quality, and strives to provide customers at home and abroad with the highest quality products and the most thoughtful service. The products are now sold all over the country and exported to more than 70 countries and regions including the United States, Europe, Canada, Russia, Norway, Czech Republic, Australia, Germany, the Netherlands, Poland, Argentina, Brazil, South Korea, India, Singapore, etc. Customer recognition and praise.

Based on the principle of reputation first, quality first, and customer focus, the company integrates product cultural heritage and corporate culture, and is committed to building a world-leading fermentation system engineering equipment under the brand " TONSEN" .

CUSTOMER FEEDBACK

SALES SERVICE

Our Service:

1.Our market team can serve you in 24 hours, so please feel free to contact at your convinent.

2.Our dedicated engineers can supply 2D,3D drawing for you if you needed.

3.If you need to inspect our factory, we can book the hotel and make the invitation letter for you.

4.Our market team with our engineer with more than 10 years experiences together can satisfy you with any technology problem;

5.Customize machine can be offered(voltage,material,dimension,heating source and so on)

After-service:

1.When shippment, we will supply a whole set of parts for backup.

2.If there is any parts damaged, we are surely can send the part to you in 24 hours.

3.Main machine is 3 years warranty, auxiliary machine is 12 months warranty,

4.Electrical components is 12 months warranty, life long service.

PAKCING &SHIPPING

PACKING & SHIPPING

1)All tanks will be packed with soft protection material and mounted on steel frame

2)All accessories and spare parts will be packed with soft protection material and then put into iron box

3)After loaded into containers, all equipment will be fixed to the containers.

* Less capital investment, quick return

* Flexible configuration, easy follow brewing

* Health, safety life style, and potential market

Investing a brewery in local region

* Cope with the hand-brew market demand

* Customize design,meet the diverse need

* Warranty for 3 years and lifetime repair guarantee

Increasing brewery production

* Rapid production increasing

* Volume flexible,easy installation

* Small investment help business thrive

Large brewery upgrading project

* Technical renovation and transformation

* Field design and execution

* Professional & Focused

WHY CHOOSE TONSEN

freely.

Three years warranty on main equipment, One year warranty on spare partsand auxilloary equipment.

Please leave messsage in below to get our latest quote and equipment list for beer filter or turnkey brewery.