- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1 kg

-

Model Number::

-

PVDF folded Filter

-

Filter media::

-

PVDF folded Filter

-

Micron Rating::

-

PVDF 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um

-

Outer/Inner Cage, End caps::

-

Reinforced Polypropylene

-

After-sales Service Provided:

-

No overseas service provided

-

Outer/Inner Diameter(mm):

-

69/33

-

Length(based on DOE end caps):

-

10"- 254mm, 20"- 508mm, 30"-762 mm, 40"- 1016mm

-

Normal Operating Temperature::

-

Up to 65℃ (140℉)

-

Normal Flow direction::

-

4.2 bar (60 psi) at 25℃ (77℉)

-

connector::

-

222-flat/DOE/226-fin /222/fin

Quick Details

-

Core Components:

-

Filter

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

TS Filter

-

Weight (KG):

-

1 kg

-

Model Number::

-

PVDF folded Filter

-

Filter media::

-

PVDF folded Filter

-

Micron Rating::

-

PVDF 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um

-

Outer/Inner Cage, End caps::

-

Reinforced Polypropylene

-

After-sales Service Provided:

-

No overseas service provided

-

Outer/Inner Diameter(mm):

-

69/33

-

Length(based on DOE end caps):

-

10"- 254mm, 20"- 508mm, 30"-762 mm, 40"- 1016mm

-

Normal Operating Temperature::

-

Up to 65℃ (140℉)

-

Normal Flow direction::

-

4.2 bar (60 psi) at 25℃ (77℉)

-

connector::

-

222-flat/DOE/226-fin /222/fin

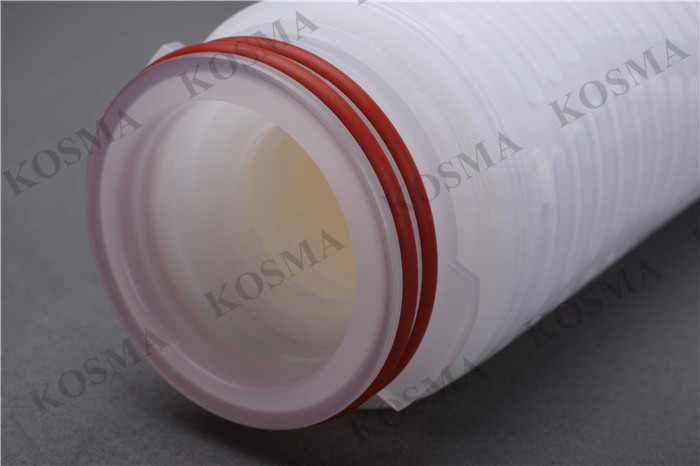

Hydrophobic PVDF Membrane folded filter cartridge 0.1um 10inch

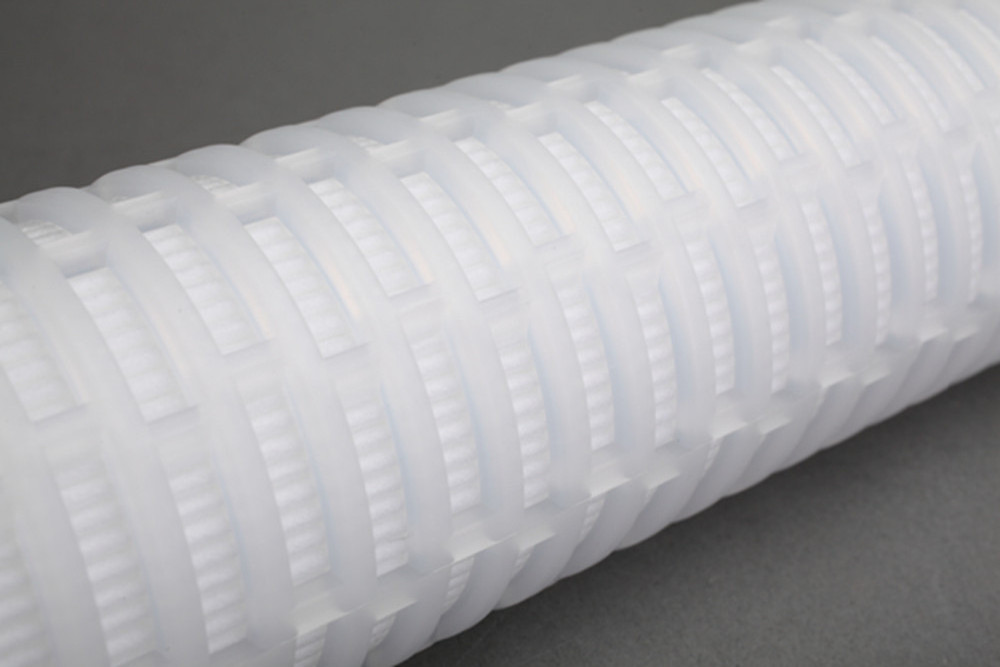

Pharmaceutical grade PVDF membrane filter cartridges are made of hydrophilic polyvinglidene fluoride (PVDF) membrane with excellent retention characteristics, flow rates and low protein binding.

These filters are particularly suited for critical applications in the biopharmaceutical production, as media, vaccines, water for injection (WFI), and other liquids for membrane filter replacement.

Features and Benefits

- Hydrophobic PVDF membrane for gas and solvents sterile filtration

- Absolute rating, filtration effective is ≥99.99%, Minimum micron to 0.1um

- Wide Chemical compatability, low protein binding

- 100% integrity test

Typical Applications

- Fermentation air

- Tank vent;

- Compressed air;

- Sterile filtration of aggressive solvents/gases

| Specifications | ||||||

| Materials Of Construction | Filter Media: | Hydrophobic PVDF Membrane | ||||

| Support Layers: | Polypropylene | |||||

| Micron Rating: | 0.1, 0.2, 0.45, 0.65, 1.0, 3.0 um | |||||

| Inner core: | Reinforced Polypropylene | |||||

| Outer Cage, End caps: | Reinforced Polypropylene | |||||

| Seal Method: | Thermal Bonded, No Adhesives | |||||

| O-rings/gaskets: | Silicone, Nitrile, EPDM, Viton, , etc | |||||

| Cartridge Dimensions | Outer Diameter | 69mm(2.75'') | ||||

| Inner Diameter | 33mm(1.30'') | |||||

| Length(based on DOE end caps) | 10"- 254mm, 20"- 508mm, 30"-762 mm, 40"- 1016mm | |||||

| Filtration Area(m2) | 0.65 m 2 per 10'' | |||||

| Operating conditions | Normal Operating Temperature: | Up to 65℃ (140℉) | ||||

| Max.Operating Temperature: | 90℃ (194℉) at P≤1.0 bar (14psi) | |||||

| Max. Differential Pressure | ||||||

| Normal Flow direction: | 4.2 bar (60 psi) at 25℃ (77℉) | |||||

| Reverse flow direction: | 2.1 bar (30psi) at 25℃ (77℉). | |||||

| PH Value compatibility: | 1-13 | |||||

| Sterilization: |

Steam Sterilization for 30 minutes at 135℃(275℉)

Cumulative Time: 50hours |

|||||

| Cartridge Safety | Endotoxin: | <0.25 EU/ml | ||||

| Extractables: | 0.03g / 10" | |||||

Typical air flow rate @ 25 ℃ (10")

100% Integrity Test

| Cartridge Code | Bubble Point | |

| DPV020 | ≥0.6bar (8.7psi) | |

| DPV045 | ≥0.35bar (5.1psi) | |

| DPV100 | ≥0.20bar (2.9psi) | |

| * Test Liquid: 70%/30% IPA/WATER at 23℃ (73℉) | ||

ORDER INFORMATION

| GRADE | PRODUCT | MICRON | ADAPTER | LENGTH | O-RING / GASKET | |

| P-PHARMACEUTICAL | DPV | 020-0.2um | AA- DOE | 10-10" | S-silicone; N-nitrile | |

| F-FOOD & BEVERAGE | 045-0.45um | CN-226/FIN | 20-20" | E-epdm ; T- (encaptulated) | ||

| H-Chemical | 100-1.0um | BN-222/FIN | 30-30" | V-viton | ||

| BF-222/ FLAT SEAL | 40-40" | How to Order?- Example | ||||

| CF-226/FLAT SEAL | 05-5" |

Pharmaceutical grade; Micron:0.45um; Length:10" ADAPTER: DOE; Gakset: Silicone. Selection Code is: PDPV045AA10S |

||||

| EN-222 three locking ears /Fin | Other-XX | |||||