- Product Details

- {{item.text}}

Quick Details

-

Table Travel (Z) (mm):

-

300 mm

-

Travel (W-axis) (mm):

-

300 mm

-

Range of Spindle Speed(r.p.m):

-

118 r.p.m

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ShenRui

-

Weight (T):

-

0.3 T

-

Product name:

-

Portable Line Boring & Bore Welding Machine

-

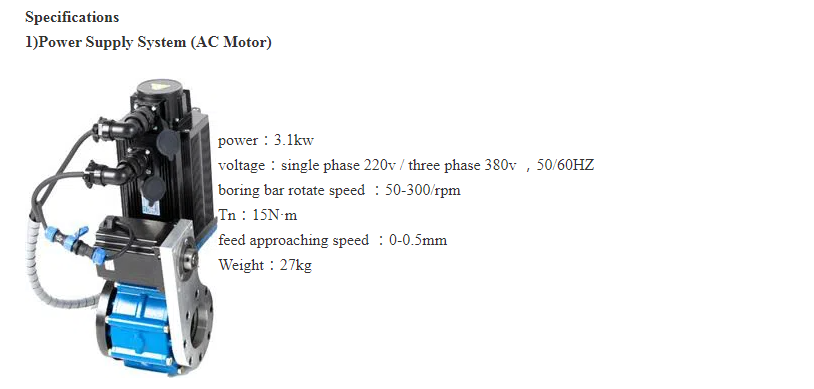

power:

-

3 KW servo motor

-

Automation:

-

Automatic

-

voltage:

-

single phase 220v / three phase 380v ,50/60HZ

-

boring bar rotate speed:

-

40-300/rpm

-

Boring and welding Hole diameter:

-

40mm~300mm

-

welding wire specification:

-

0.8mm / 1.0mm / 1.2mm.

-

Function:

-

Combine line boring and welding into one machine

-

Boring Length:

-

can be customized

-

lead time:

-

5-7days

Quick Details

-

Table Size (mm):

-

Other

-

Table Travel (X) (mm):

-

300 mm

-

Table Travel (Y) (mm):

-

300 mm

-

Table Travel (Z) (mm):

-

300 mm

-

Travel (W-axis) (mm):

-

300 mm

-

Range of Spindle Speed(r.p.m):

-

118 r.p.m

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ShenRui

-

Weight (T):

-

0.3 T

-

Product name:

-

Portable Line Boring & Bore Welding Machine

-

power:

-

3 KW servo motor

-

Automation:

-

Automatic

-

voltage:

-

single phase 220v / three phase 380v ,50/60HZ

-

boring bar rotate speed:

-

40-300/rpm

-

Boring and welding Hole diameter:

-

40mm~300mm

-

welding wire specification:

-

0.8mm / 1.0mm / 1.2mm.

-

Function:

-

Combine line boring and welding into one machine

-

Boring Length:

-

can be customized

-

lead time:

-

5-7days

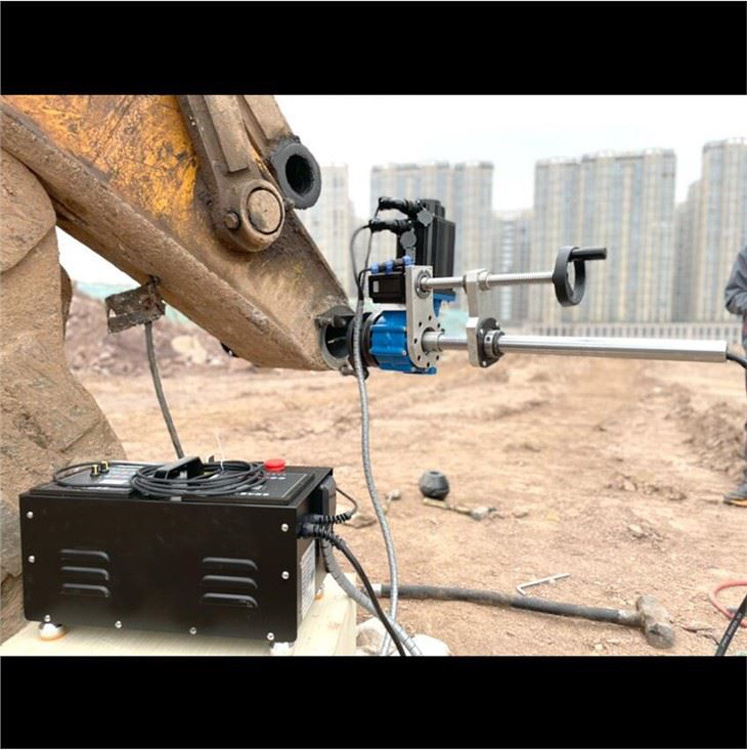

Portable line boring and welding machine

Portable line boring and welding machine is an on-site portable machining/welding machine , repair bores which have been worn out, oversized or irregular shaped. It combine line boring and welding two function into one machine .Against modular design, welding bar allow directly install on the line boring machine frame. Make it immediately switch and start welding work after hole boring ,save much time and better efficiency. our line boring machine exported to India ,Malaysia ,Vietnam ,Indonesia ,Phillipine ,Thailand ,Russia etc

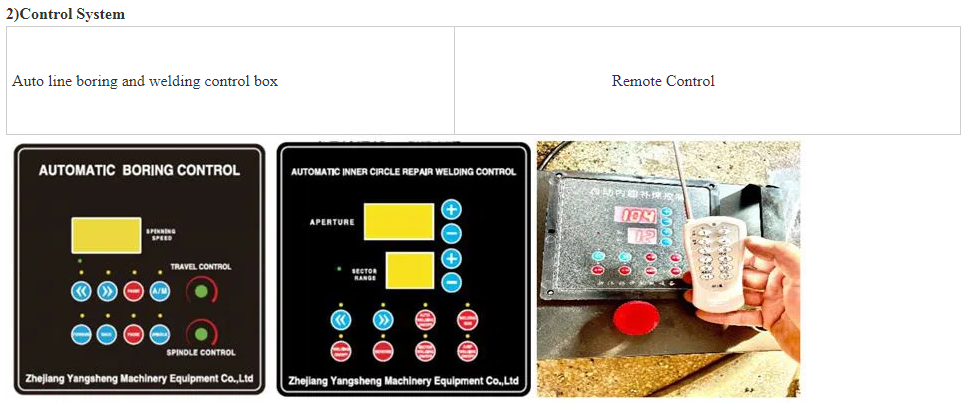

Line Boring and welding diameter is 40mm~600mm ; Modular design, it can be easy assembled and disassembled on site ,minimum effect by the site location and space. Maximum piece weigh 27KG ,it can be operated by one person. Boring and welding two function combine into one machine, client can easy handle and switch boring and welding mode in one machine. Protection system, install intelligent power supply technology, when the voltage fluctuates, control box can make the output stabilized. And If there is over voltage/current/overload, protection will be activated to switch off machine. Remote control, it can operate by remote control operation.

Product Details:

Applications

Boring and welding diameter is 40mm~300mm ; Combine line boring and welding into one machine , against lightweight ,smaller size ,strong power supply, make all repair process very easy to installation and operation .

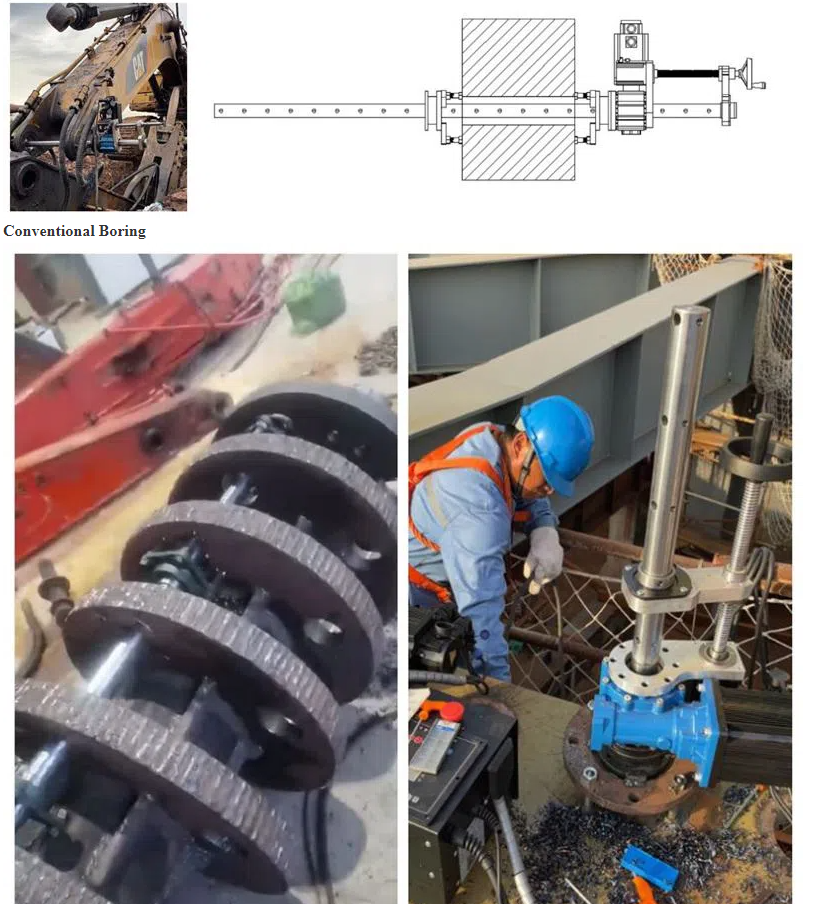

Line Boring

The line boring bar feed approaching have manual gear box control feed and automatic feed by motor speed regulation.

The bar rotary speed is 50-300/rpm, which can be switch in positive and negative rotary direction, and remote control.

Automatic inner hole repair welding system, can be remote control welding gun feed approaching position, set hole machine diameter. Adjust welding gun head to control fan-sector welding area.

Automatic inner hole repair welding can set skip welding, fan-sector welding, full circle welding, slot welding, etc.

1.Delivey time : Generally it is 5-10 days if the goods are in stock. Or 30 days , it's depand to quantity.

2.Packing term :export packing wooden cases, or customer customized requirements .