- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Aile

-

Power:

-

15 kw

-

Dimension(L*W*H):

-

Can be customized

-

Product name:

-

bottle washing machine

-

Function:

-

Clean

-

Application scope:

-

Chemical Cosmetic Food

-

Motor:

-

Chinese Famous Brand

-

Usage:

-

Chemical Industry

-

Control:

-

Button

-

Intermittent divider:

-

China Taiwan

-

Transducer:

-

Panasonic

-

Advantage:

-

Easy Control

Quick Details

-

Weight (KG):

-

450

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Aile

-

Power:

-

15 kw

-

Dimension(L*W*H):

-

Can be customized

-

Product name:

-

bottle washing machine

-

Function:

-

Clean

-

Application scope:

-

Chemical Cosmetic Food

-

Motor:

-

Chinese Famous Brand

-

Usage:

-

Chemical Industry

-

Control:

-

Button

-

Intermittent divider:

-

China Taiwan

-

Transducer:

-

Panasonic

-

Advantage:

-

Easy Control

Product Description

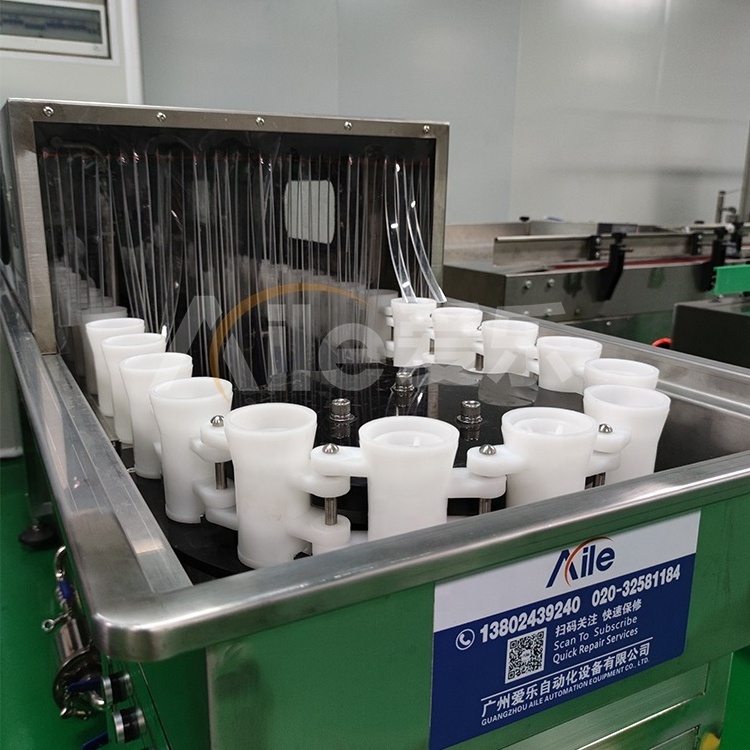

Specification

|

Rated Production Capacity

|

3000 bottles/hour

|

|

Bottle spacing

|

85mm

|

|

Number of flushing heads

|

12 heads

|

|

Chain pitch

|

50.8mm

|

|

Bottle box spacing

|

101.6mm

|

|

Operating cycle period

|

3000 bottles / hour : 14.4 seconds

|

|

Circulating water flushing time adjustable

|

10-20 seconds

|

|

Water rinser time adjustable

|

5-10 seconds

|

|

Water consumption

|

1.5-3m3 / h

|

|

Total power distribution

|

35kw

|

|

Air source pressure

|

0.6Mpa

|

|

Power supply

|

220V / 380V , 50Hz

|

Suitable for different size bottles

Not only glass bottle is available, but also perfume bottle, from glass bottle, hard plastic jar.

Hot wind drying before output

12 heads per line, equip with hot wind drying function after water flushing outside and inside.

PLC touch screen control

Machine adopt electric control and water recycling function, save cost and fast speed.

Products Description

1. This machine is a two-end intermittent operation washing, drying and cooling integrated machine, one end of the bottle enters the other end of the bottle, compact structure, using PLC programmable control technology, combined with touch screen operation interface, easy to operate, high degree of automation.

2. The main transmission adopts air cylinder transmission, with stable start and stop, intermittent operation, low wear of transmission parts and long service life.

3. Reasonable process,

water recycling

, rinse once

outside the bottle

, rinse twice with circulating water

inside the bottle,

and finally rinse once with pure water, with less water, high washing rate, and very few broken bottles.

4.Using linear bottle washing, the total

flushing time is more than 30 seconds

, and there is no water splash outside the body, which can maintain a good working environment.

5. After washing the bottle, there is a

drying time of 3-5 minutes

. The

hot air of 120-150℃

is blown into the bottle, which can meet the requirements of fast drying, and the temperature of the hot air is adjustable.]

Hot Searches