To bear 5000kg color steel coil, inner diameter is 500-508mm, Width of the raw material: 1250mm. Max bear weight 5.5Tons (You can also choose hydraulic decoiler machine with coil car and without coil car ,5Tons 8Tons ,10Tons and so on based on your choose)

- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

10 - 30

-

Coil Weight (T):

-

5 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Dimension(L*W*H):

-

1500*1000*1200mm

-

Weight:

-

0.9, 3.5T

-

Type:

-

Shearing Machines

-

Feeding width:

-

600mm-1250mm

-

Material Thickness:

-

0.3 mm~1.0 mm

-

Cutting blade materials:

-

Cr12

-

PLC Brand:

-

mitsubishi or Delta

-

Color:

-

Blue

-

Main Power:

-

5.5kw

-

Shaft diameter:

-

60mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Quick Details

-

Cutting Width (mm):

-

0 - 50 mm

-

Material Thickness(mm):

-

0.8 - 1 mm

-

Cutting Speed(m/min):

-

10 - 15 mm

-

No. of Slitting Lines:

-

10 - 30

-

Coil Weight (T):

-

5 T

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Dimension(L*W*H):

-

1500*1000*1200mm

-

Weight:

-

0.9, 3.5T

-

Type:

-

Shearing Machines

-

Feeding width:

-

600mm-1250mm

-

Material Thickness:

-

0.3 mm~1.0 mm

-

Cutting blade materials:

-

Cr12

-

PLC Brand:

-

mitsubishi or Delta

-

Color:

-

Blue

-

Main Power:

-

5.5kw

-

Shaft diameter:

-

60mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

Product Description

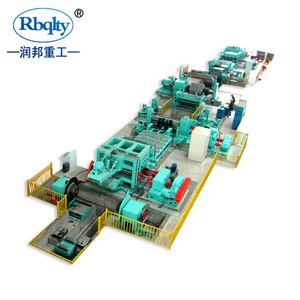

Our steel coil straighten slitting and cutting machine can produce various of steel roof and wall panel, it is a new building materials, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc. It has many advantages, such as easy installation, short building period, beauty, light weight but high strength.

|

Simple Aluminum Stainless Steel Coil Slitting Machine

|

|

|

|

Formed Material

|

PPGI PPGL GI GL

|

|

|

Equipment operation

|

Automatic

|

|

|

Voltage

|

380V 50Hz 3Phase or as your requirement

|

|

|

Thickness of sheet (mm)

|

0.3-0.8mm

|

|

|

Material width(mm)

|

As your requirement

|

|

|

Cover Width of the sheet after formed

|

as your drawing

|

|

|

The size of the roll forming machine

|

about 3500mmx1300mmx1400mm

|

|

|

Speed

|

15-20m/min

|

|

|

Diameter of shaft

|

80mm

|

|

|

Weight of the Machine

|

3000-3500KGS

|

|

|

Material of rollers

|

Cr12

|

|

|

Motor brand

|

According to customer demand

|

|

|

PLC

|

Siemens or Delta or Mitsubishi

|

|

|

Total power (kw)

|

11Kw

|

|

|

Power of hydraulic system

|

4Kw

|

|

|

Power of main molding core

|

4Kw

|

|

|

Rollers' material

|

45# steel with chromn on the surface

|

|

|

Wall thickness of main forming machine

|

16mm

|

|

Production Flow

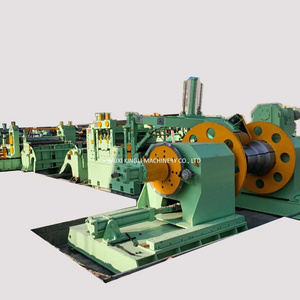

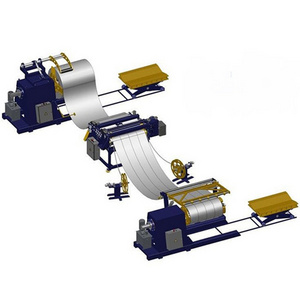

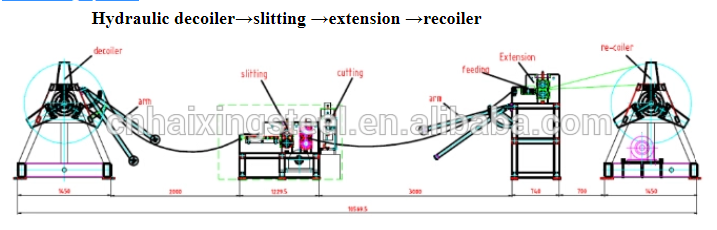

The used steel coil straighten slitting and cutting machine includes in decoiler, guiding device, slitting device, cutting device, length measure device, extension device, re-coiler, hydraulic station and PLC controlling system.

Details Images

Down 6rollers,5 for up, four for down

Leveling rollers diameter:80¢

Material of rollers: ASTM #45 with chrome

The Function is to flatten the material for easy slitting, this equipment include 3 sets blade

It adopts industrial computer to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.Transducer brand :EURA PLC :Mitsubishi Panasonic Siemens or Delta

This is composed of frame, big bearing-stand, recoiling axle, recoiling expansion device, expansion recoiling plate .Function: used for collect the strips which cutted by slitter.

Our Services

1. Warranty :14Months,and we will provide technical support for whole life of the equipment.

2. Delivery time: Within 30-45days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine

and also train your workers/technician face to face.

Without visiting,we will send you user manual and video to teach you to install and operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things

2. Delivery time: Within 30-45days after deposit receipt your payment

3. Guarantee period: 18months free service/ pay service all the machine life

4. Installation and training

If buyers visit our factory and check the machine, we will teach you how to install and use the machine

and also train your workers/technician face to face.

Without visiting,we will send you user manual and video to teach you to install and operate.

If buyer needs our technician to go to your local factory,please arrange board and lodging and other necessary things

Related product

Certifications

Our Company

Tianjin Haixing Imp&Exp

company are specializing in the production of all kinds of Corrugated Metal Roofing Sheet Making Machine,Glazed roof tile roll forming machinery ,double roof making machine ,floor deck machine,curve roof machine ,ridge cap roof forming machine , Electric motor decoiler coil machine,different sizes roofing sheet,PPGI/GI ,Alu-Zinc steel coils , Galvanized steel coils ,Galvanized steel sheet ,Galvalume steel coils/sheet ,cold/hot rolled sheet /coils , professional service and favorable price , satisfied with the quality ,welcome to every customers come to visit and buy ! We will 24 hourse services for you ,please don't hesitate to contact us when you need .

Hot Searches